Why is everyone talking about automation and robotics? Figures, trends and real impacts

Over the last two years, robotics has gone through a complex phase: the market has seen a significant drop in orders, with a 23% decline

Welcome to Robo Feed, your trusted partner in industrial innovation. We specialise in the

development of robotic islands for servicing CNC machines and offer a complete technical,

electronic and mechatronic support service for your machine park.

With our state-of-the-art

technology solutions, you can improve production efficiency, reduce downtime and cut

operating costs.

Contact us today for a personalised consultation and start on the path to a more efficient and competitive future.

Our robotic cells are designed to automate and optimise the servicing of CNC machines,

guaranteeing precision and continuity of production. Robo Feed supports you in

developing and configuring solutions that improve the efficiency of your machining

operations, reducing cycle times and increasing overall production capacity. Discover our

robotic cells and find the perfect configuration for your production needs.

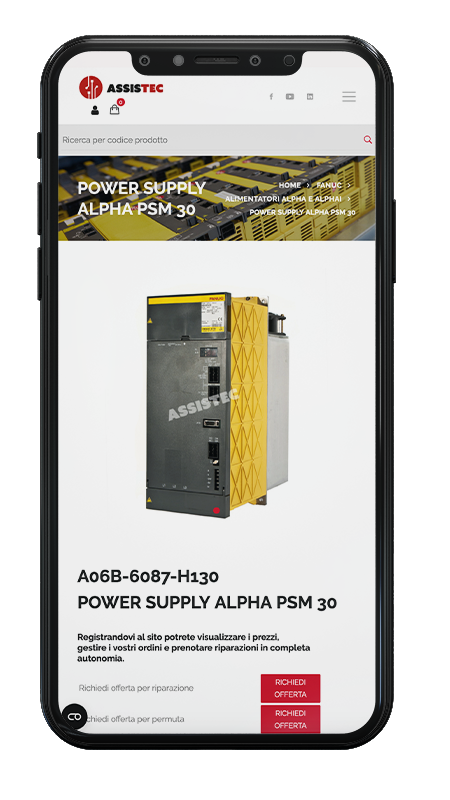

With established know-how from Assistec, we offer a comprehensive and highly

specialised robotics service, integrating expertise in technical

support for CNC machines and robots, advanced electronic support and integrated

mechatronic support.

Our continuously trained technicians intervene promptly on Fanuc robots and cobots, as well as on our Robo Feeds and robot cells, ensuring fast and tailor-made solutions.

Automatic handling to optimise time and reduce costs.

Integrate automated systems for turning, milling and other machining operations.

Advanced technology to handle components accurately, even in dirty conditions.

Thanks to our experience, we can support your production with complex machining

operations. These include:

Solve today’s problems, build tomorrow’s success. At Robo Feed, we have the solution to

the challenges your business faces every day.

Smart strategies to improve productivity and stay competitive.

Solutions for flawless and consistent results.

Optimise your processes: Reduce waste and inefficiency.

Technologies to suit your needs and demand.

Eliminate burdensome tasks to protect the health and safety of your team.

Make the most of every square metre with smart, scalable solutions.

Make the most of every square metre with smart, scalable solutions.

The Bin Picking system project was developed with the support of the European Union and other funding bodies such as:

Over the last two years, robotics has gone through a complex phase: the market has seen a significant drop in orders, with a 23% decline

In the world of industrial production, where precision and speed are everything, robots are now the beating heart of automated lines. But if technology is

The Italian industrial landscape is undergoing a period of significant change. Following the success of the National Industry 4.0 Plan, which has supported thousands of

Assistec and ROI-Calculator by FANUC help you calculate an accurate estimate of the return on investment for automated servicing robots.

Active Installs

Destinations

Countries

Premium Users

Get 10% discount on your first purchase