Welcome to the era of advanced industrial automation, where efficiency meets innovation, with no compromises. We’re thrilled to present our partnership with KEYENCE Italia, an outstanding Japanese company in the field of sensors, measuring systems and artificial vision, to introduce the RB series 3D Robot Guide into the world of Bin Picking.

Our commitment to maximum quality and efficacy has prompted us to integrate Keyence’s RB-1200 3D vision system into our demo showroom and into an operating unit on the premises of one of our customers. This leading-edge technology is key to our Bin Picking system, radically changing our approach to object handling.

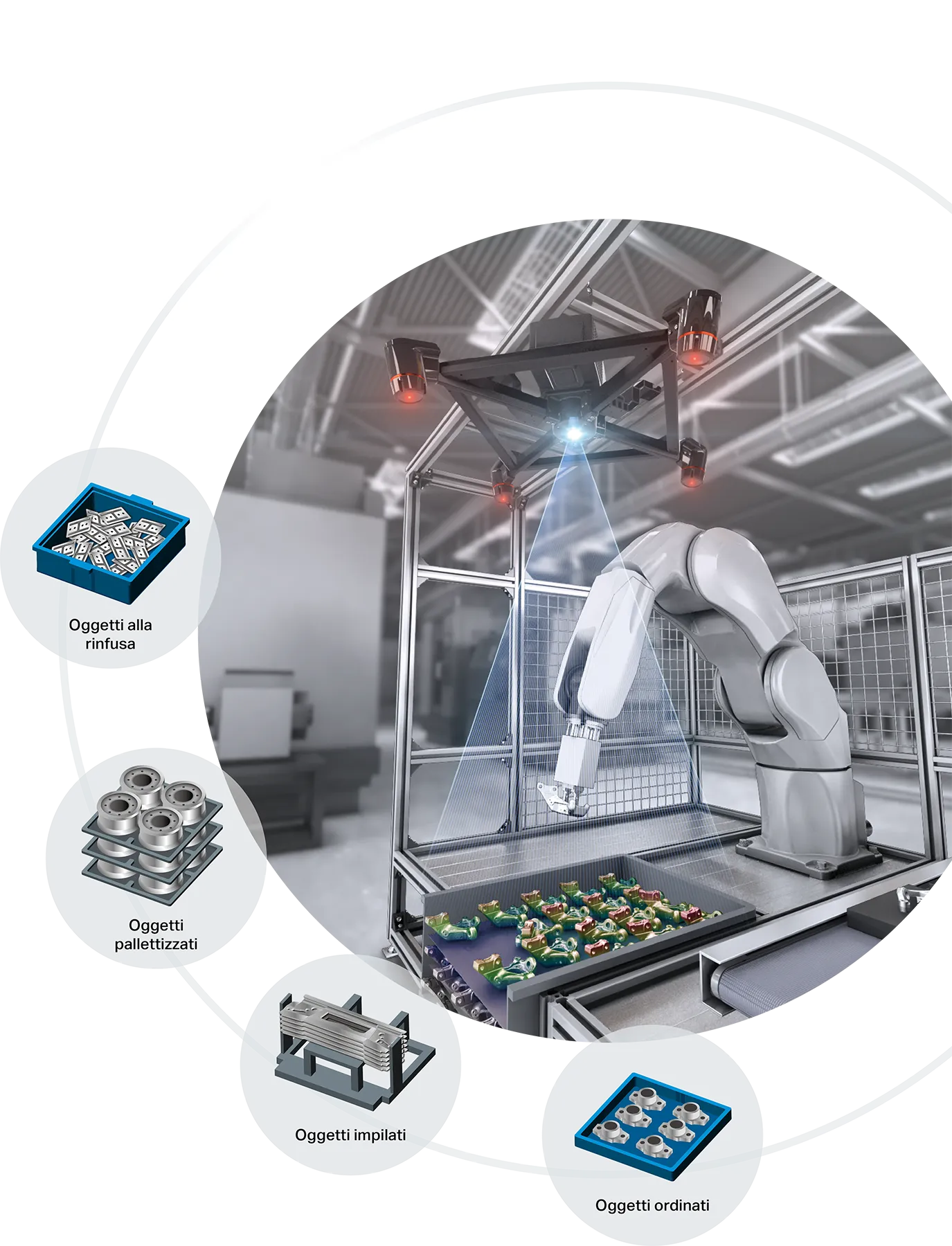

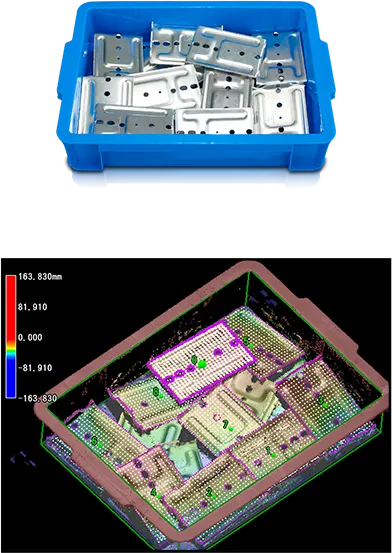

3D CV-X robot guide technology, model RB-1200, is a system equipped with 4 cameras and a single structured light projector. The high-speed 3D imaging makes it possible to reduce working time, while the high resolution and rapid processing boosts the overall efficacy of the process.

Even with a large visual field, lighting remains uniform right across the image, guaranteeing a stable search. Distortion is kept to a minimum thanks to the inclination angles of the four cameras.

The 3D positions are calculated for each piece, regardless of orientation and inclination. Where there is a low contrast with the background, the height image enables an accurate search without external influences.

Common issues in production processes, such as the management of a variety of recipes, the handling of large or easily damaged components and the speed limitations or expensive errors that can be caused by manual working, can be effectively resolved with the 3D vision system.

The stand-out feature of this system is its high efficacy in terms of costs, safety and stable operation.

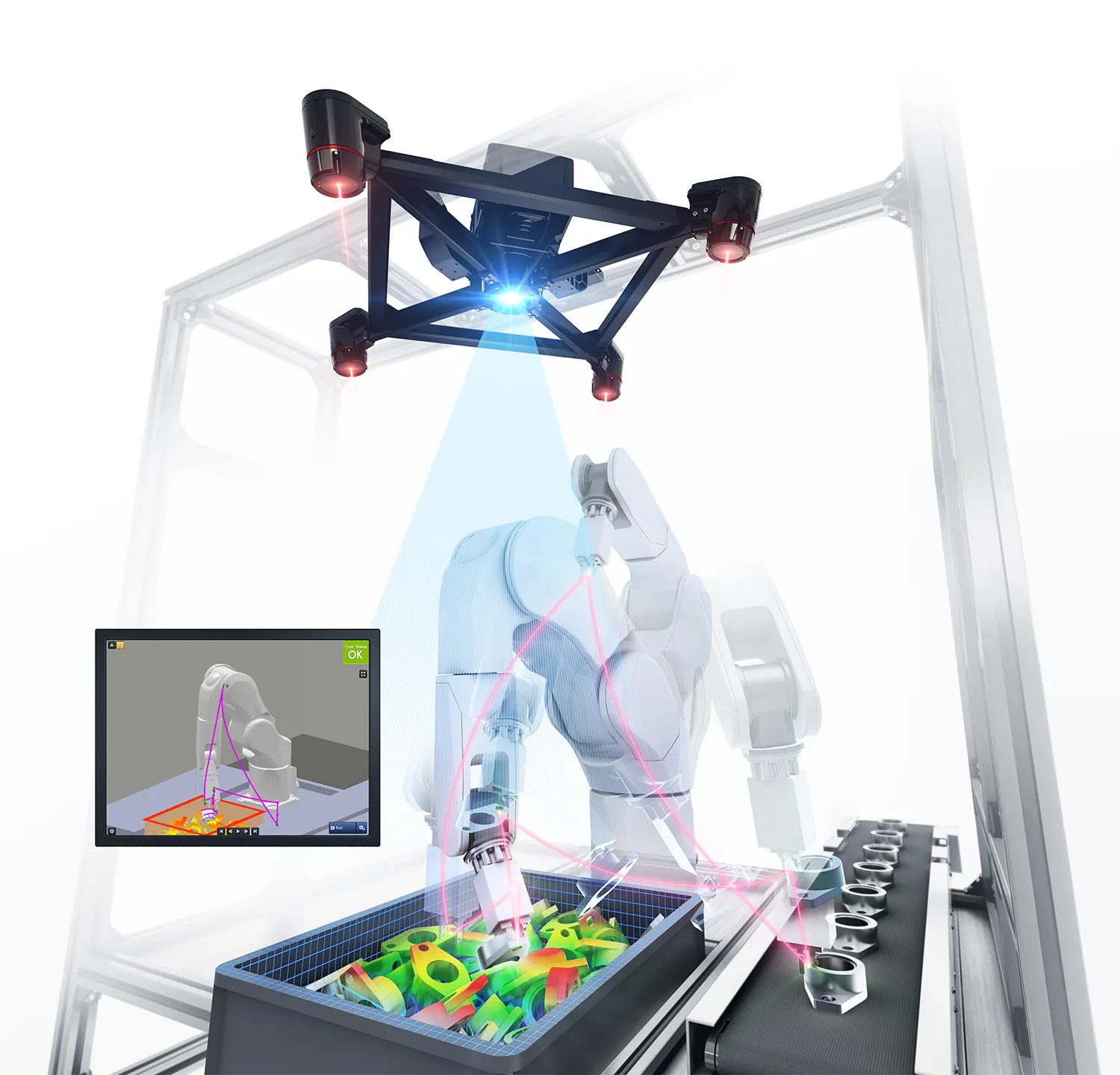

The 3D search algorithms and optical systems developed by KEYENCE offer high-precision performance and high speed, guaranteeing an automatic calculation of the movements for the robot and drastically reducing configuration time.

The complete simulation, from the generation of images to the movements of the robot, can be conducted on a PC, further simplifying the configuration process, also at the preliminary stage of the project.

In conclusion, the integration of RB series 3D CV-X vision systems is a significant step forward in the field of industrial automation. Thanks to its high precision, speed and user friendliness, this system offers effective solutions for a wide range of challenges in the production process. With the assistance of leading-edge technologies like this, we are determined to continue improving the efficiency and optimisation of industrial processes, by providing our customers with innovative, reliable solutions. If you’d like to find out more about how our 3D vision system can boost your productivity and reduce costs, don’t hesitate to contact us. We’re here to help you achieve your industrial automation aims.

Send us your requests and we will be happy to develop with you the best Robofeed solution for your company