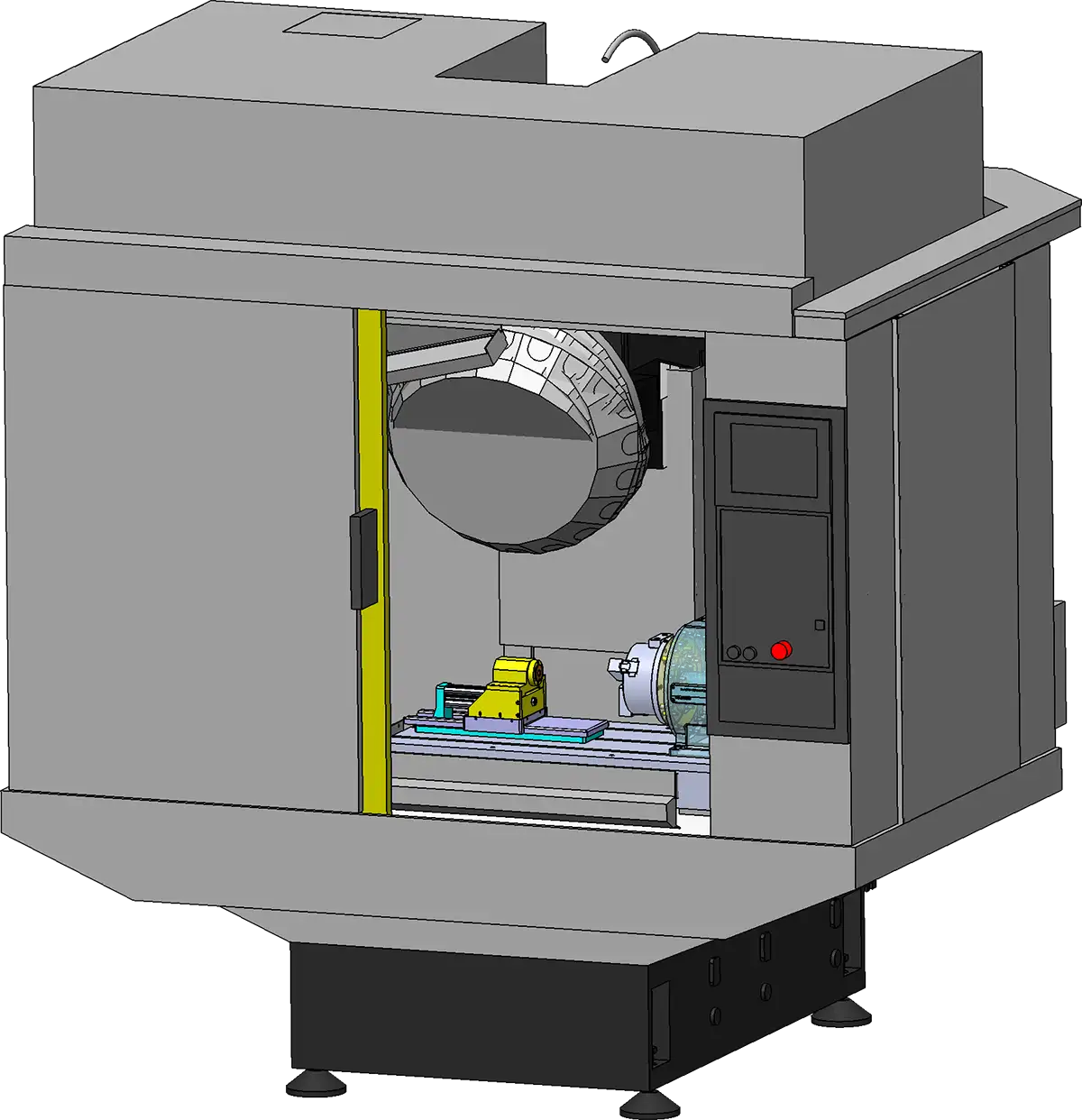

Microtools, a leading manufacturer of bespoke equipment for the processing of pipes and profiles, was faced with the challenge of automating the production process of its new RoboDrill Fanuc 4-axis machine tool, aimed at improving efficiency and reducing cycle times.

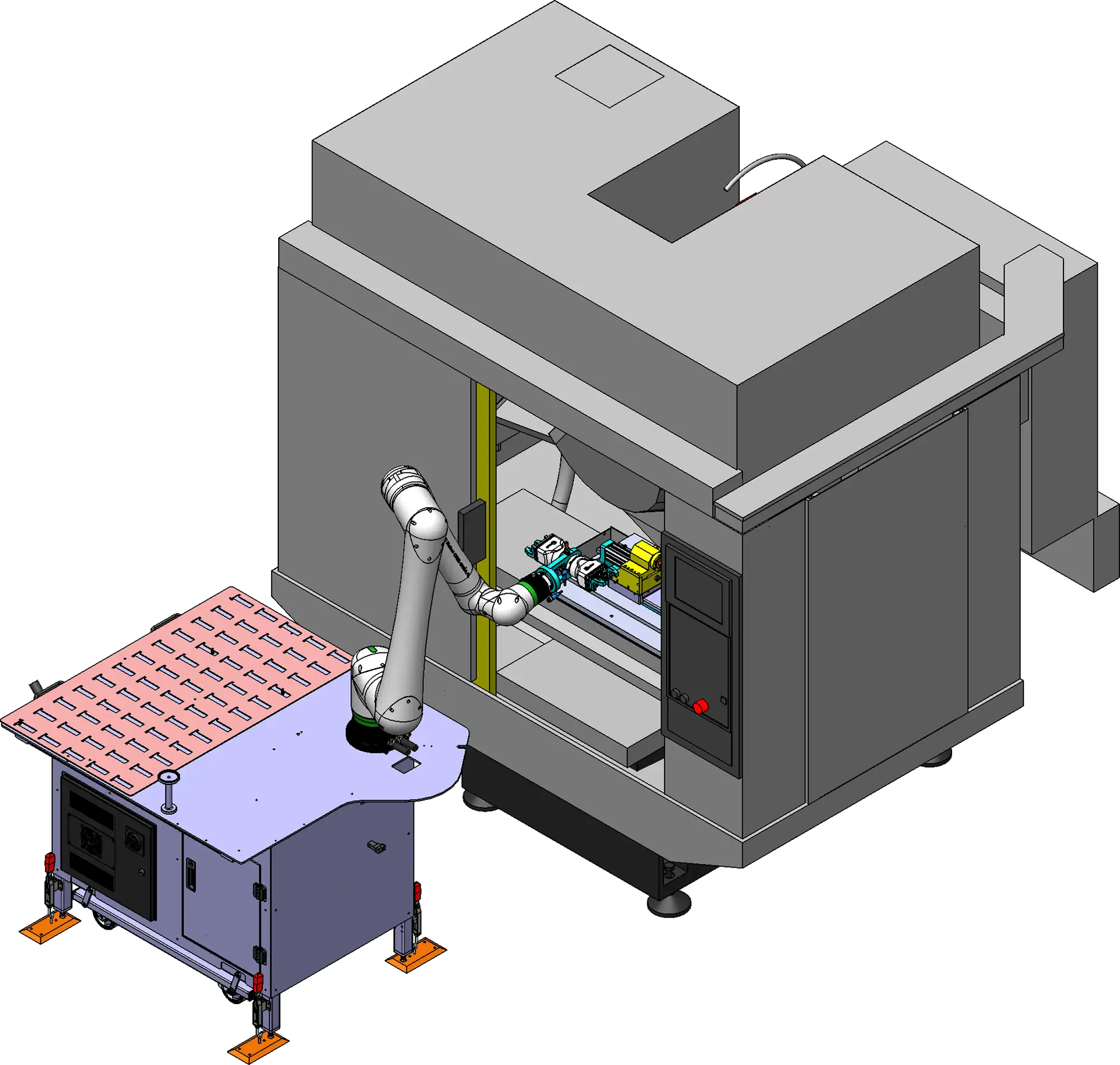

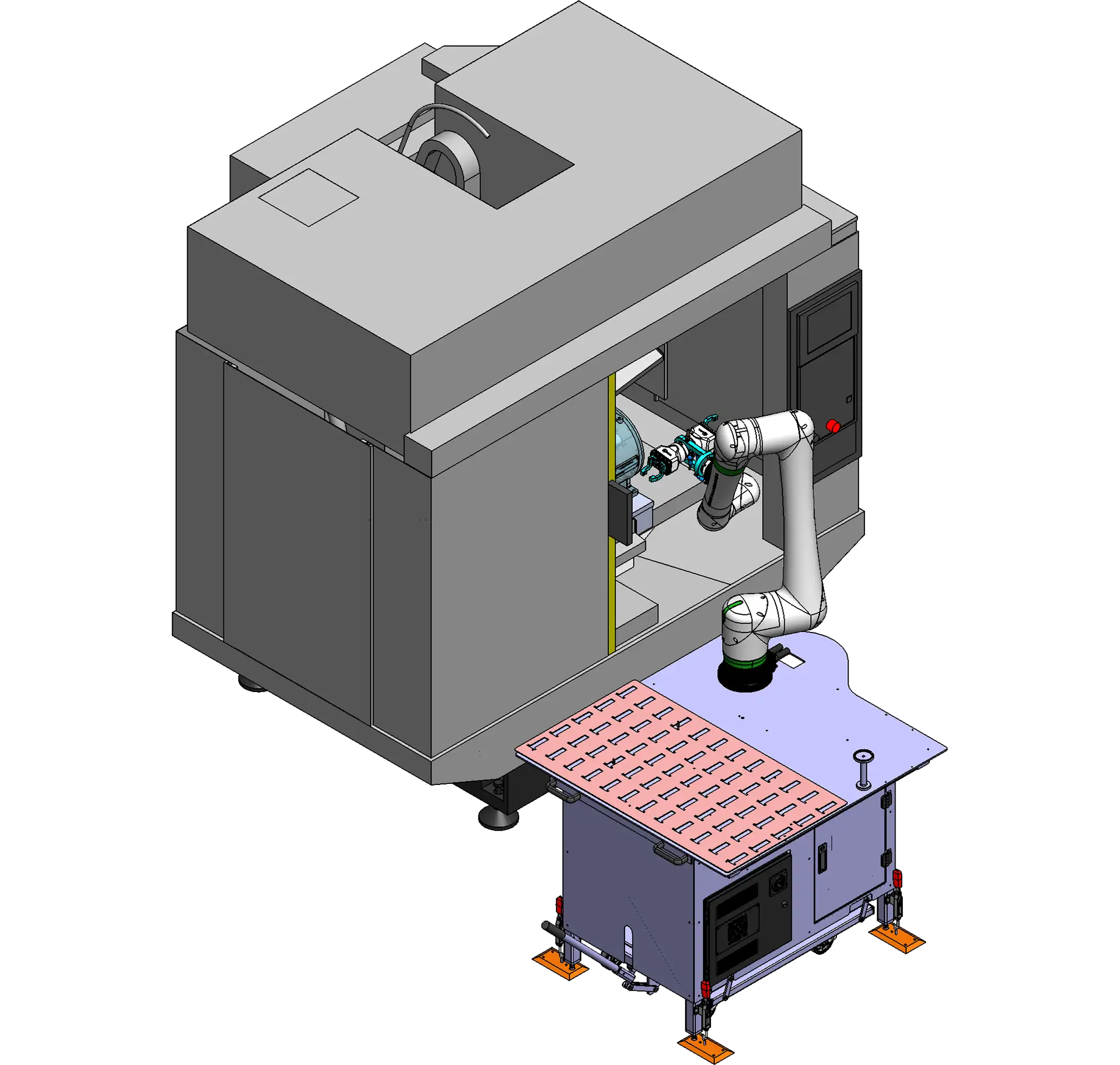

SOLUTION: ROBOFEED C21

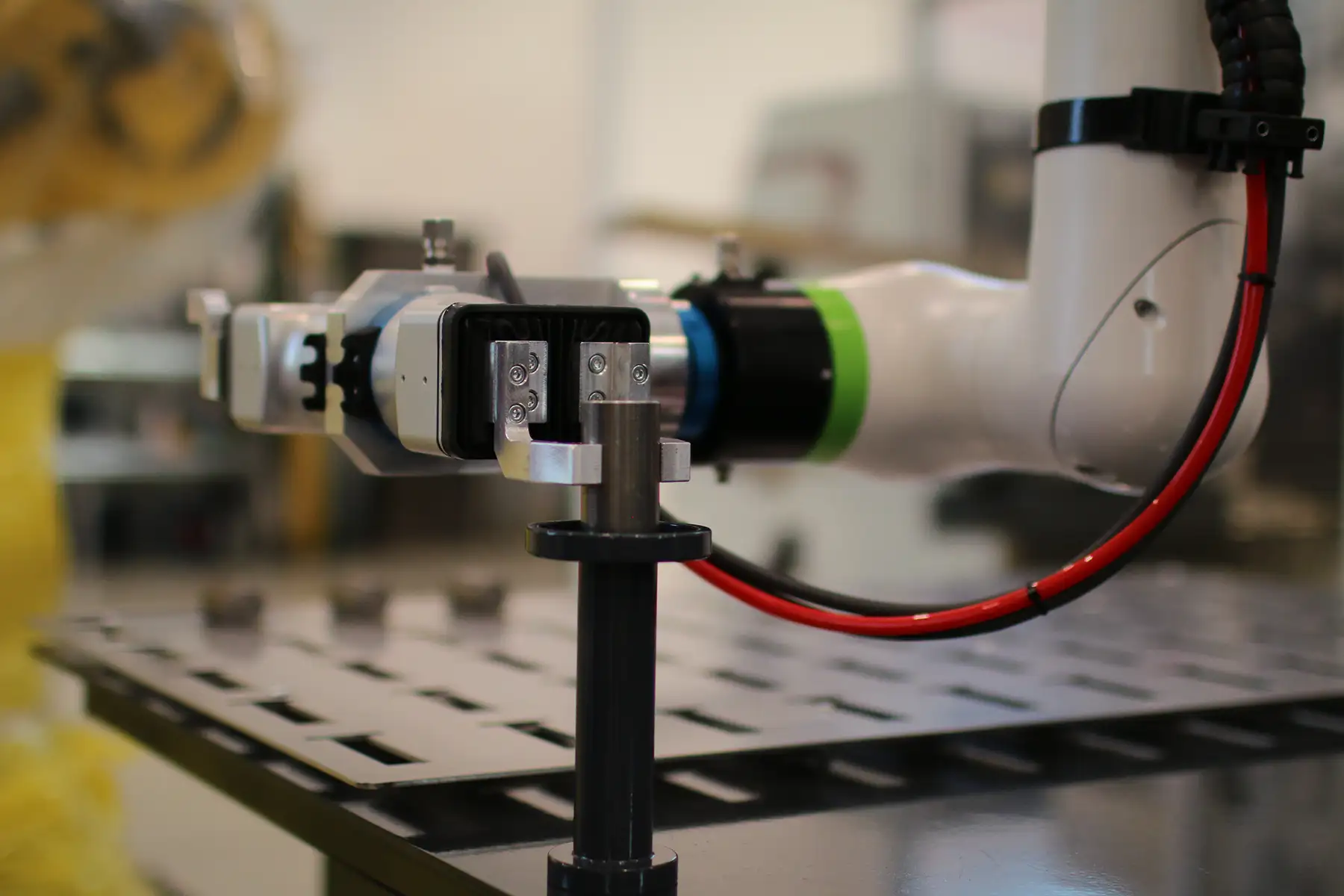

After first meeting with the customer, our Technical Team conducted an in-depth analysis that identified the RoboFeed C21 model as the most suitable solution to meet the specific requirements.

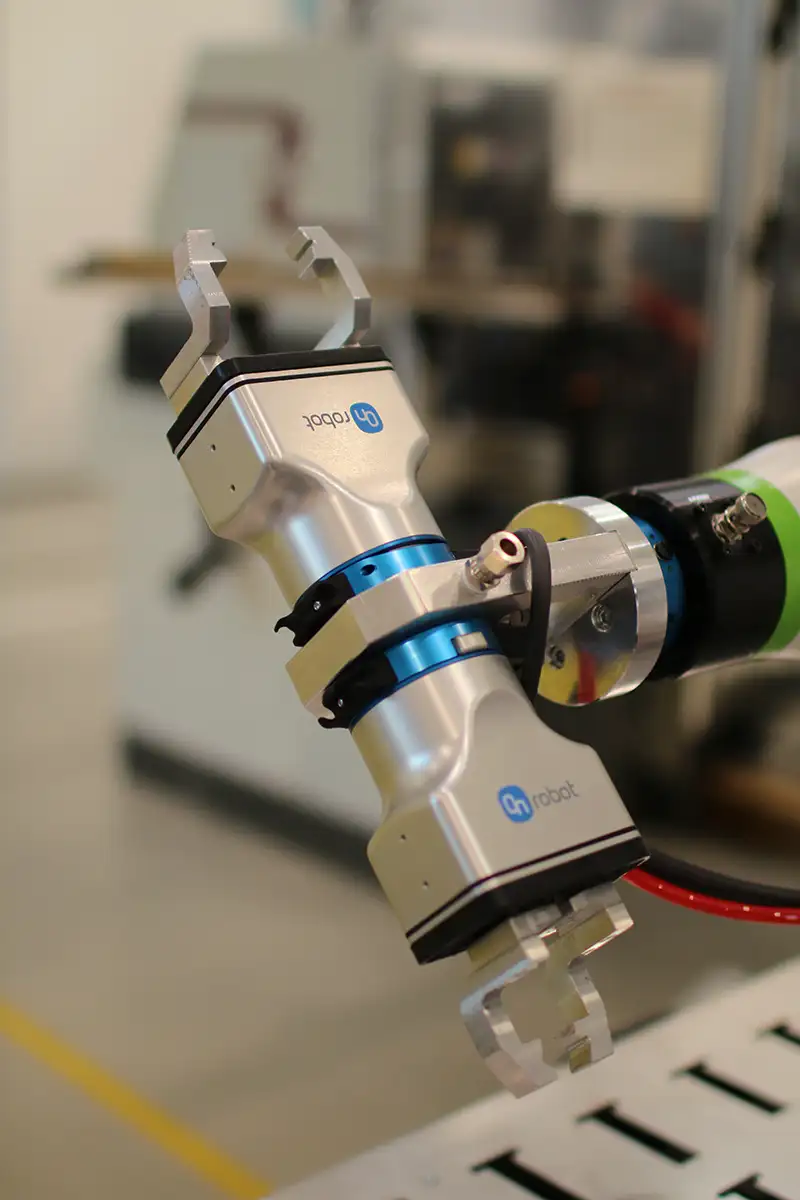

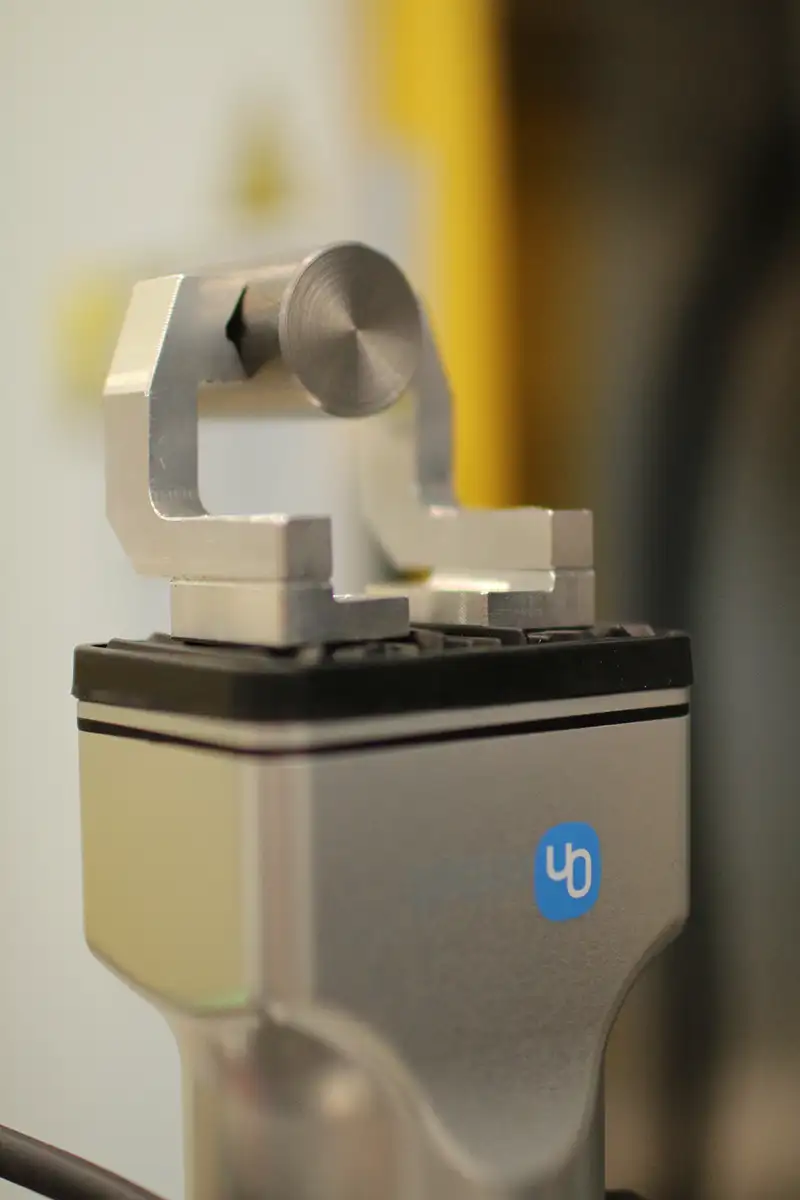

During the feasibility analysis, our Technical Team identified the need to customise the RoboFeed C21 model. This customisation, pertaining particularly to the Robot, enabled Microtools to achieve its objectives, overcoming the limitations of the standard RoboFeed C20 model with a 10kg cobot.