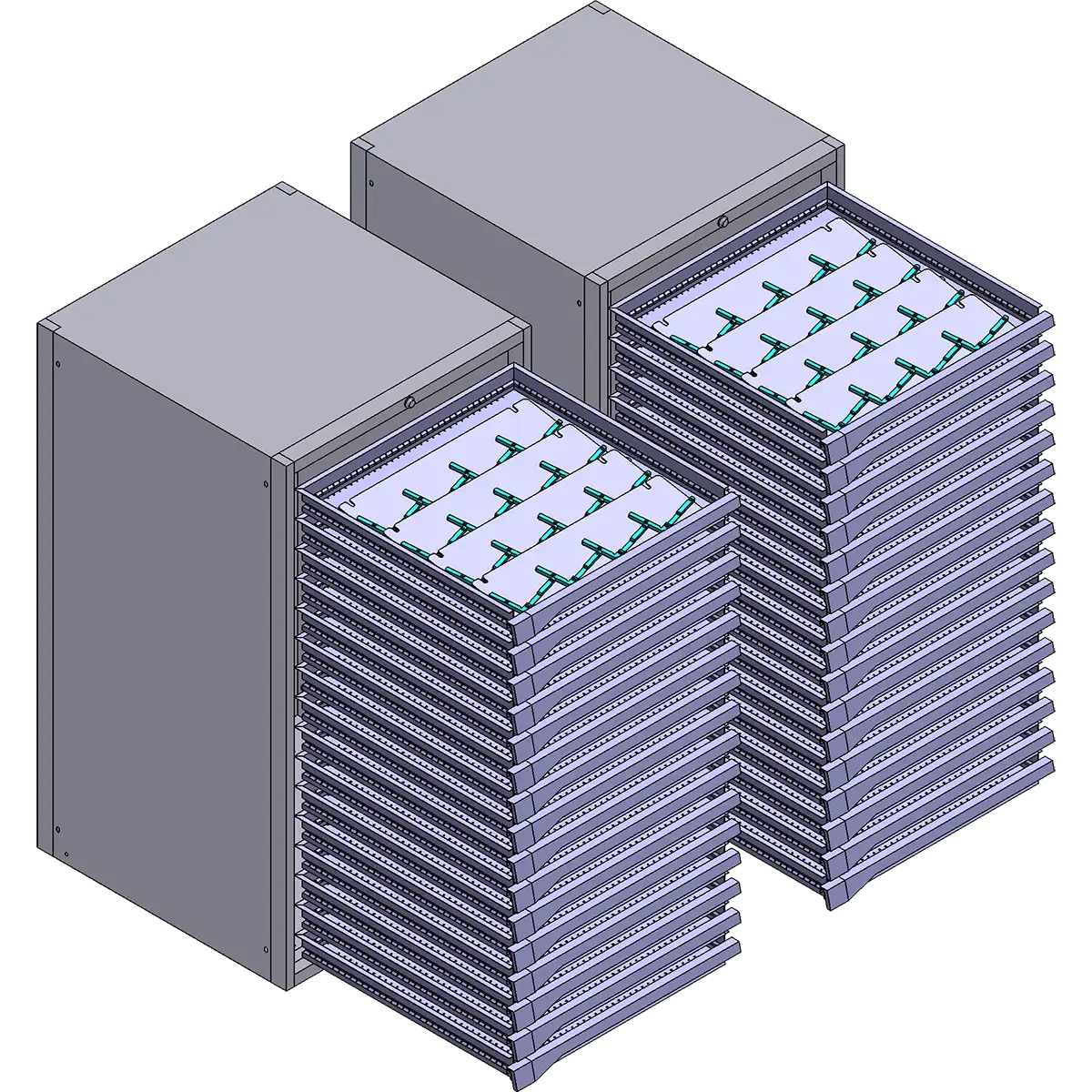

Italtronic is a leading manufacturer of plastic components for the electronics industry. The company’s decision to integrate our RoboFeed into its machine fleet stemmed from the need to increase its market competitiveness and optimise the production efficiency of a new 5-axis CNC machine tool.

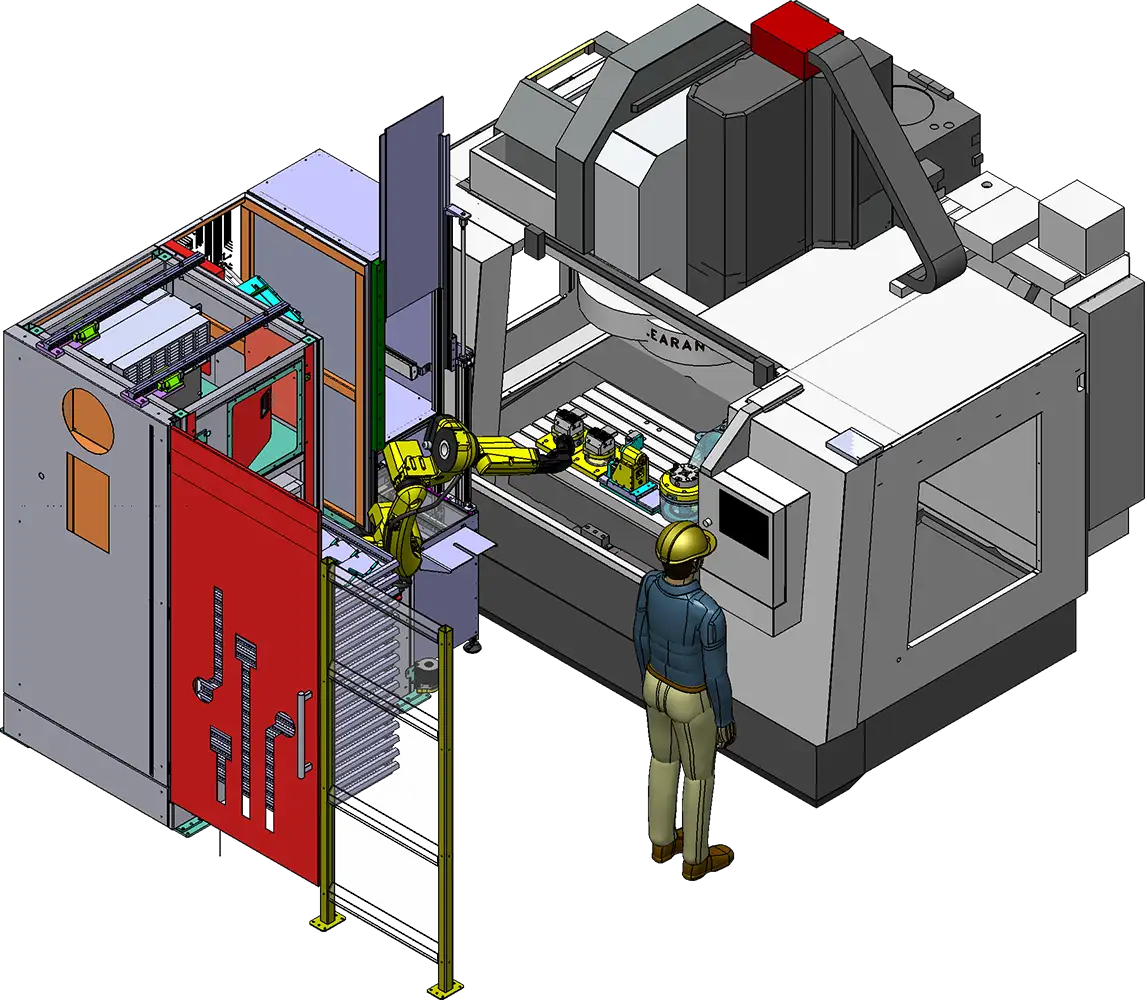

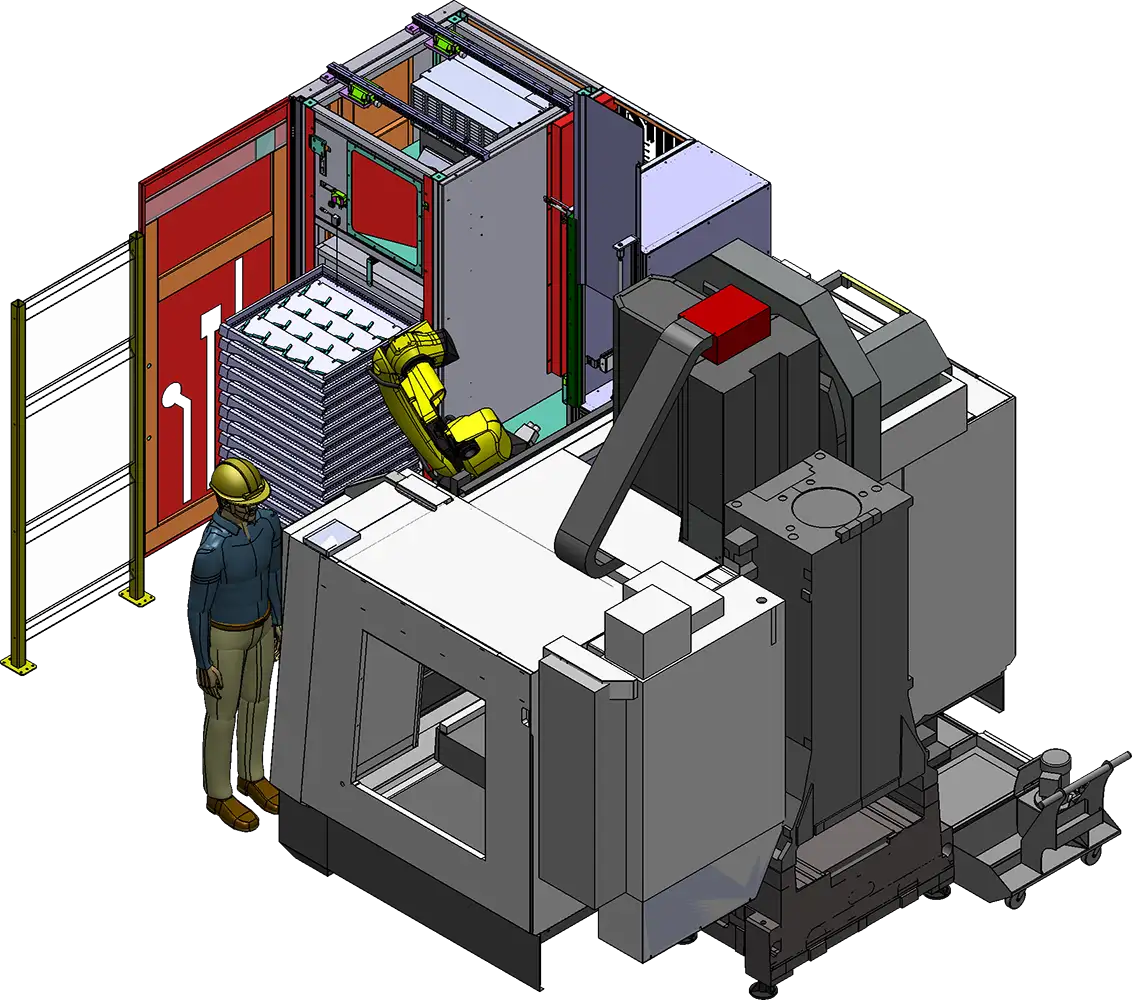

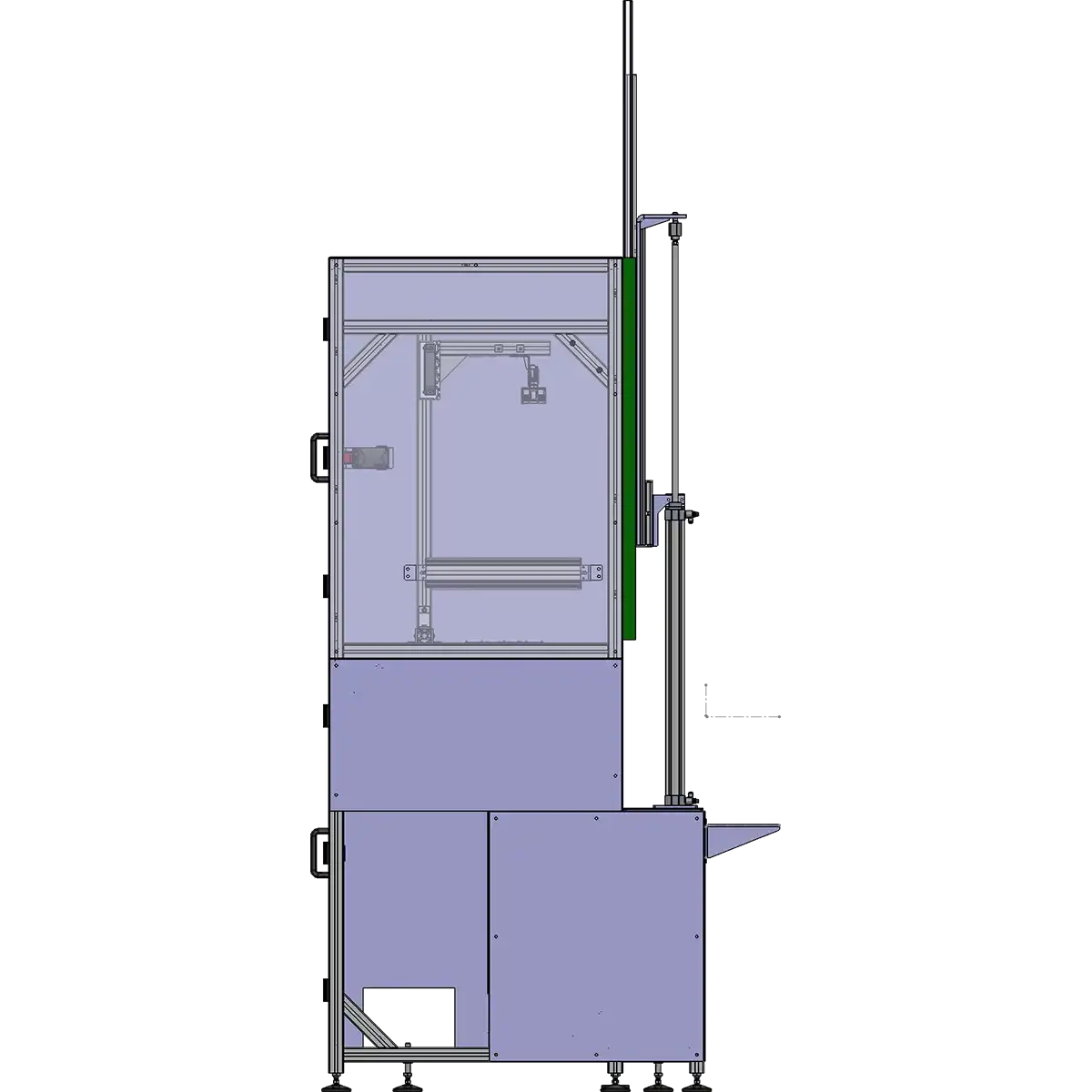

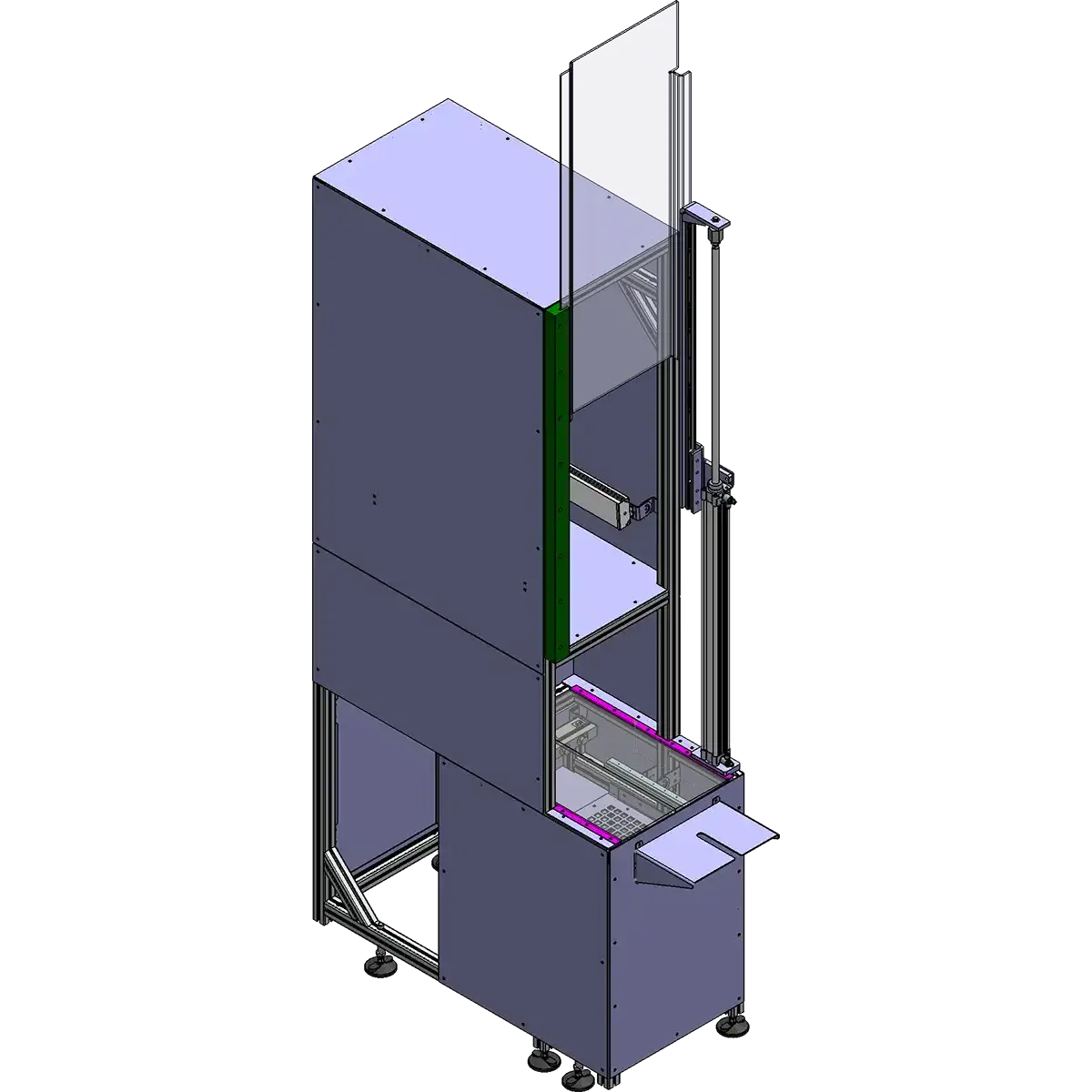

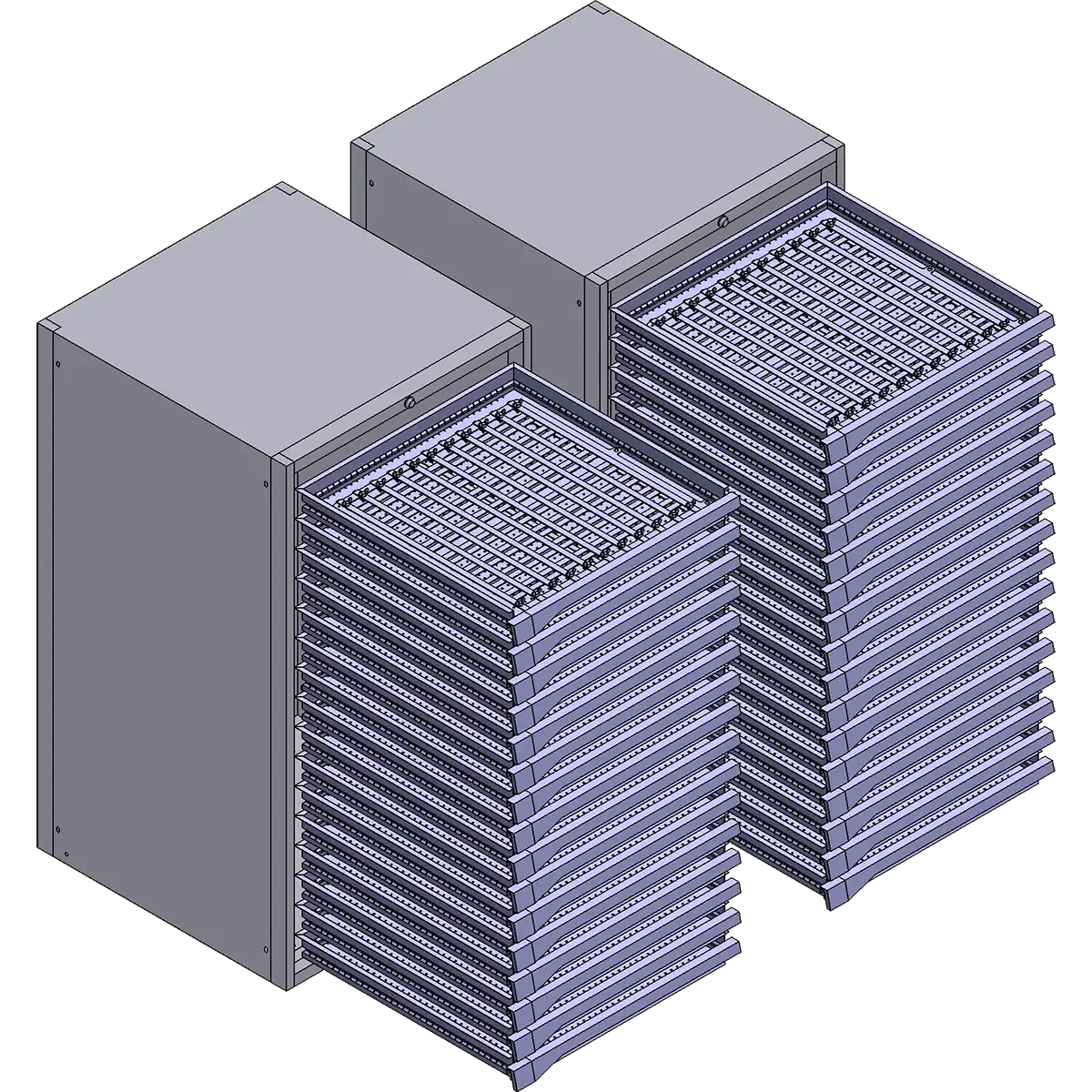

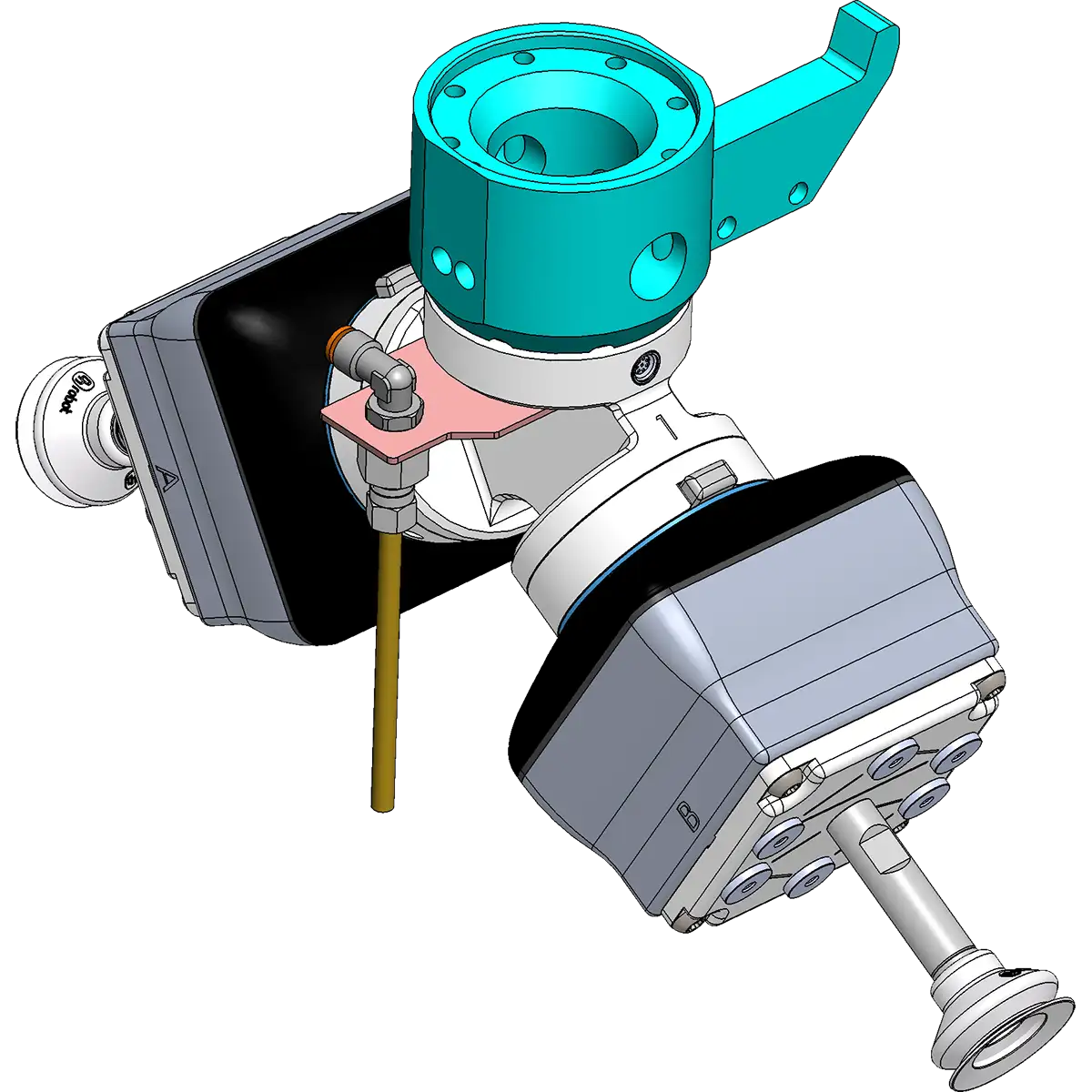

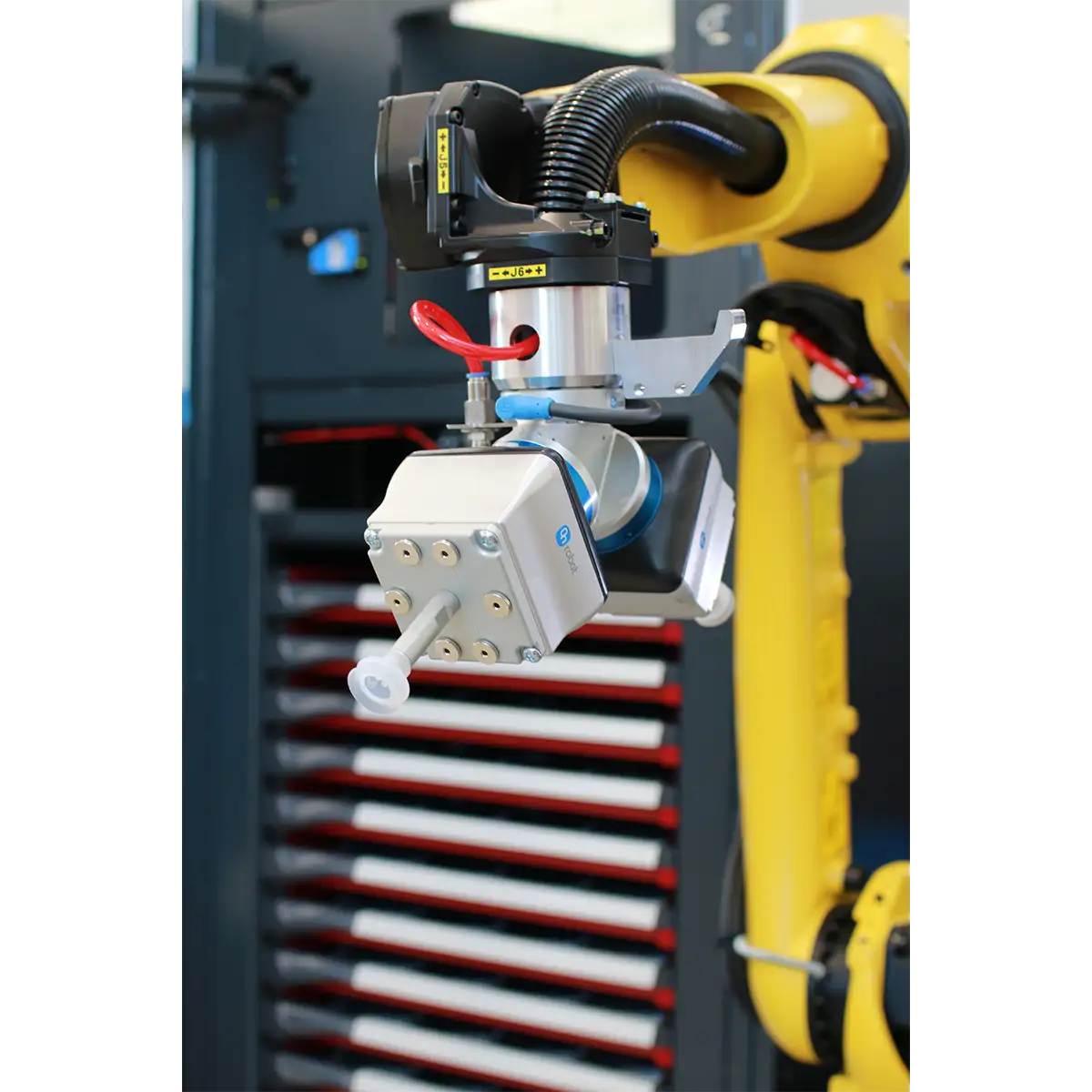

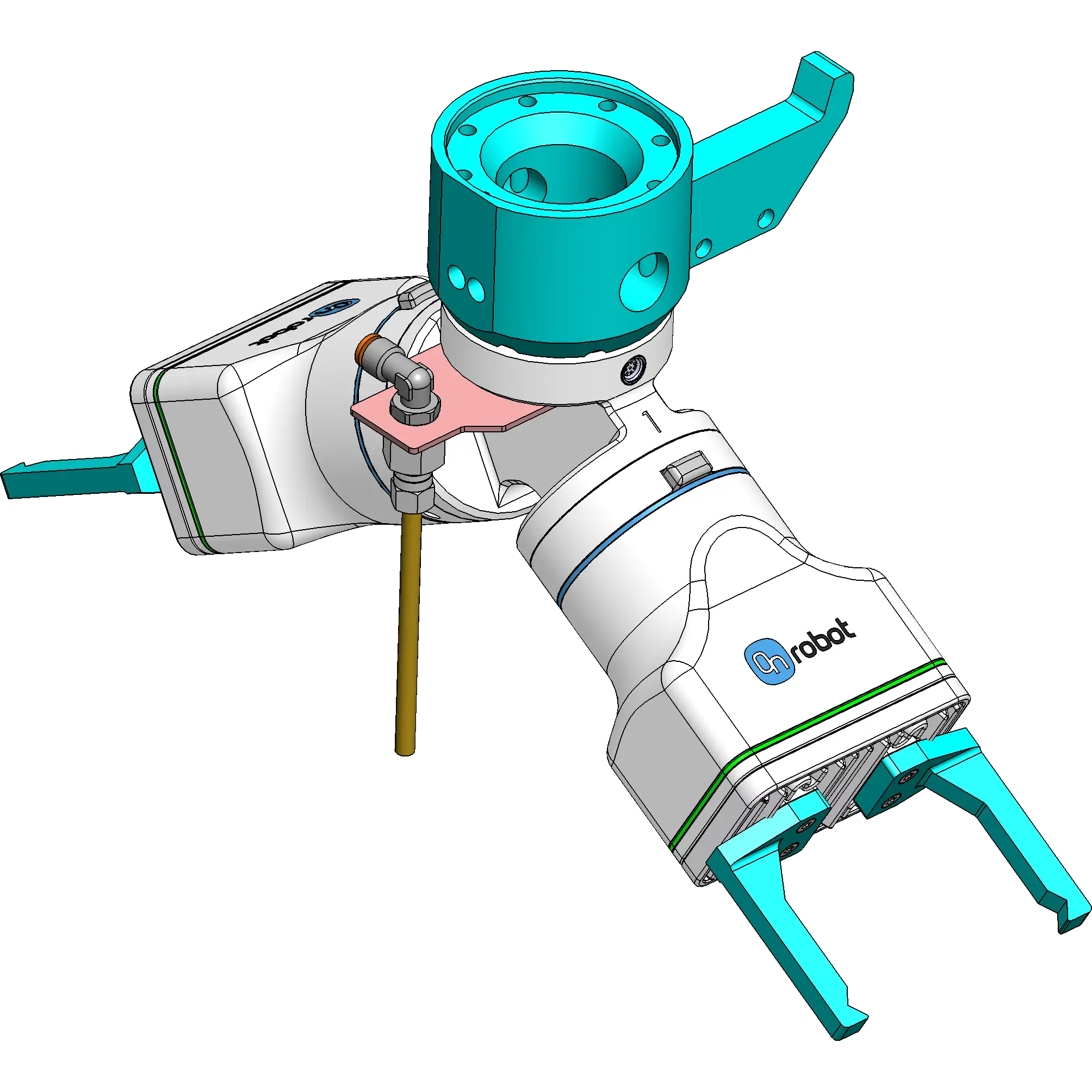

Solution: Customised RoboFeed A20

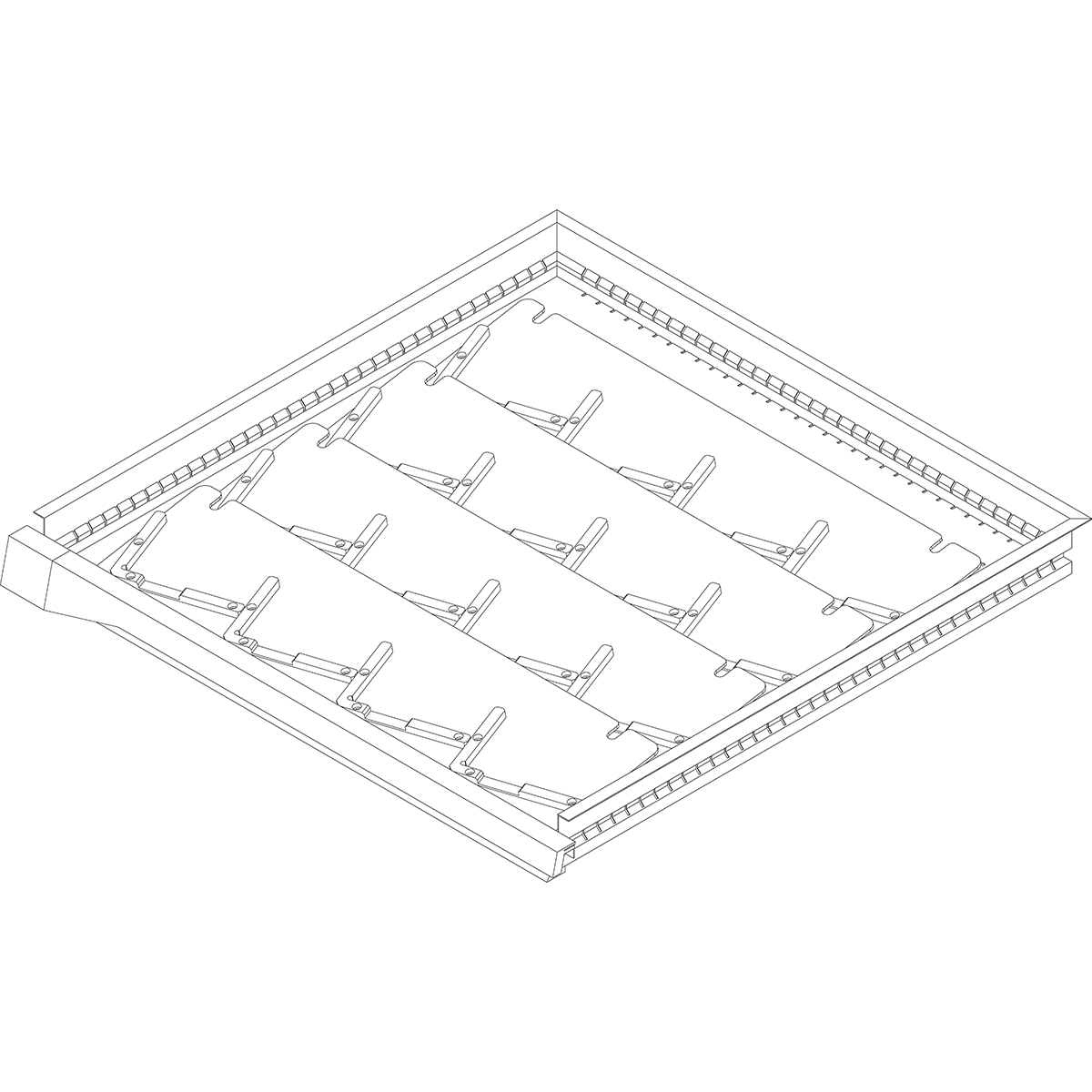

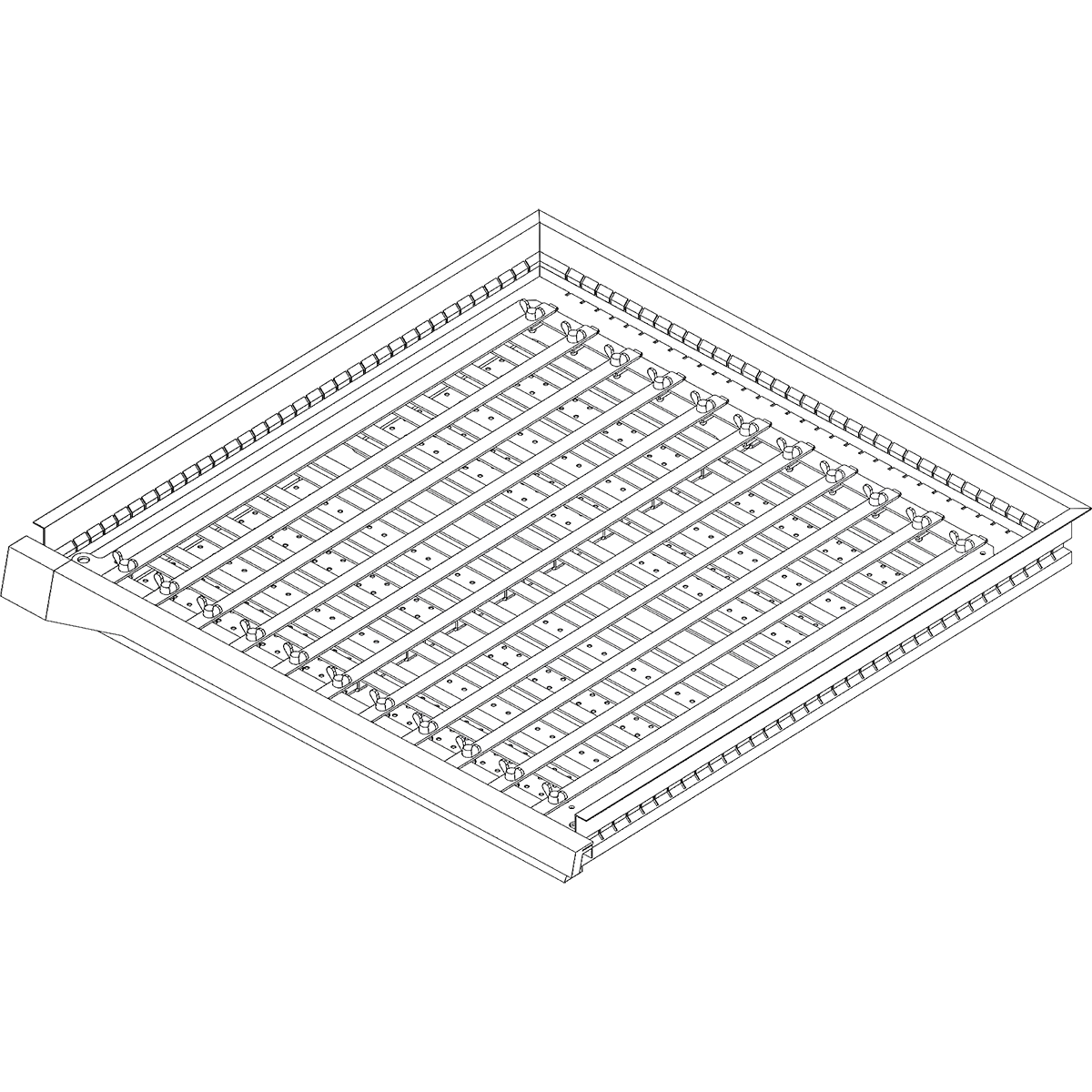

After first meeting with the customer, our Technical Team conducted an analysis that identified the RoboFeed A20 model as the most suitable solution to meet the customer’s needs.

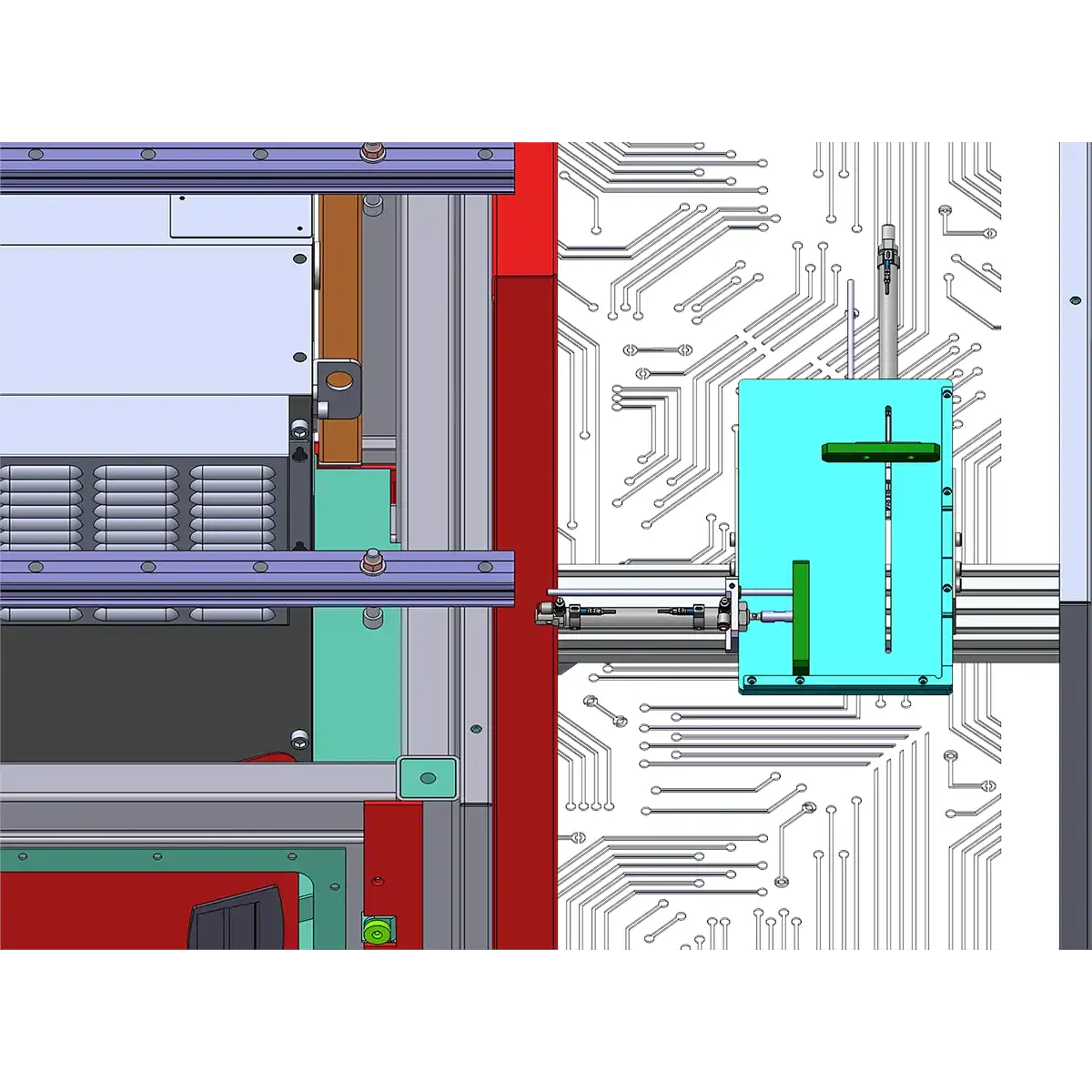

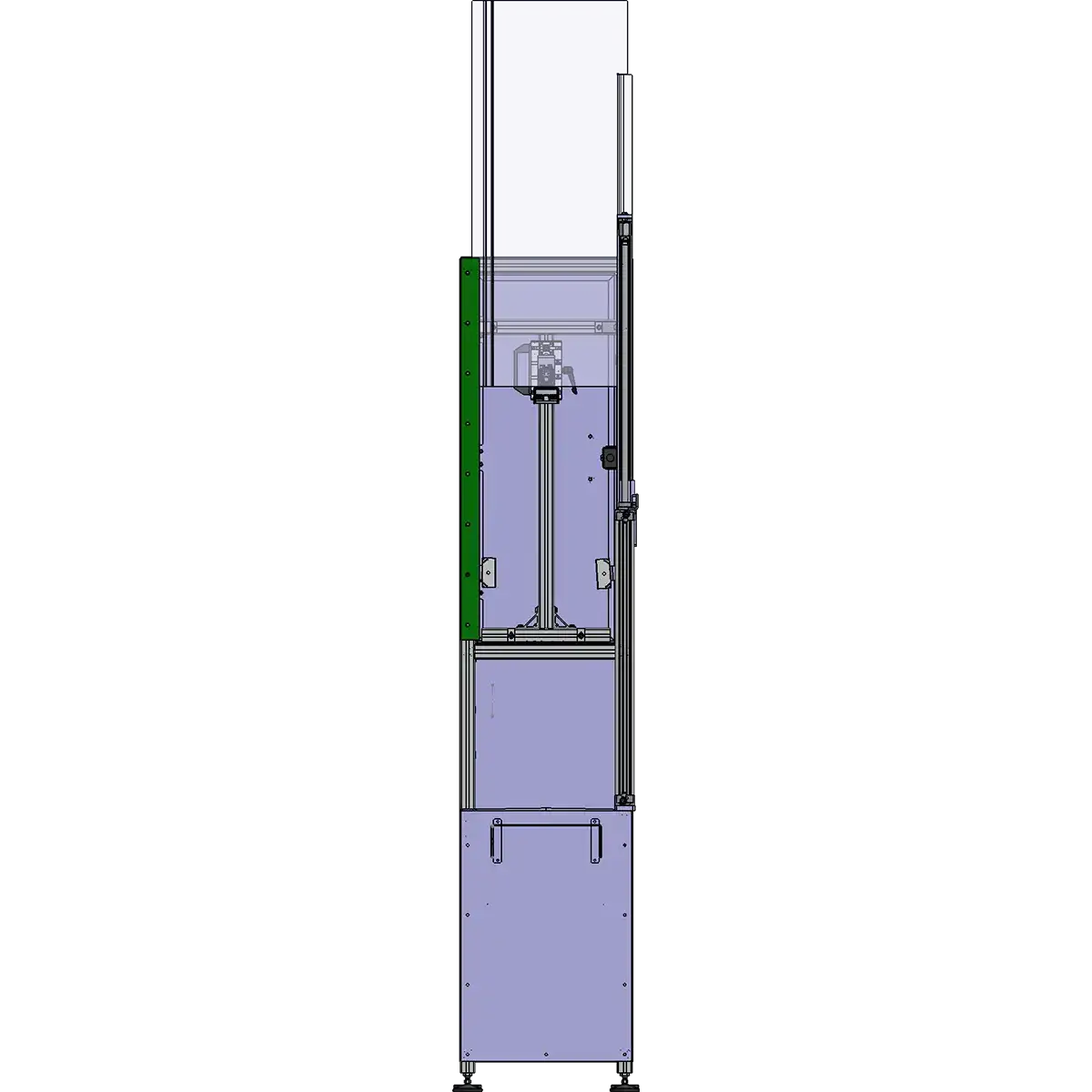

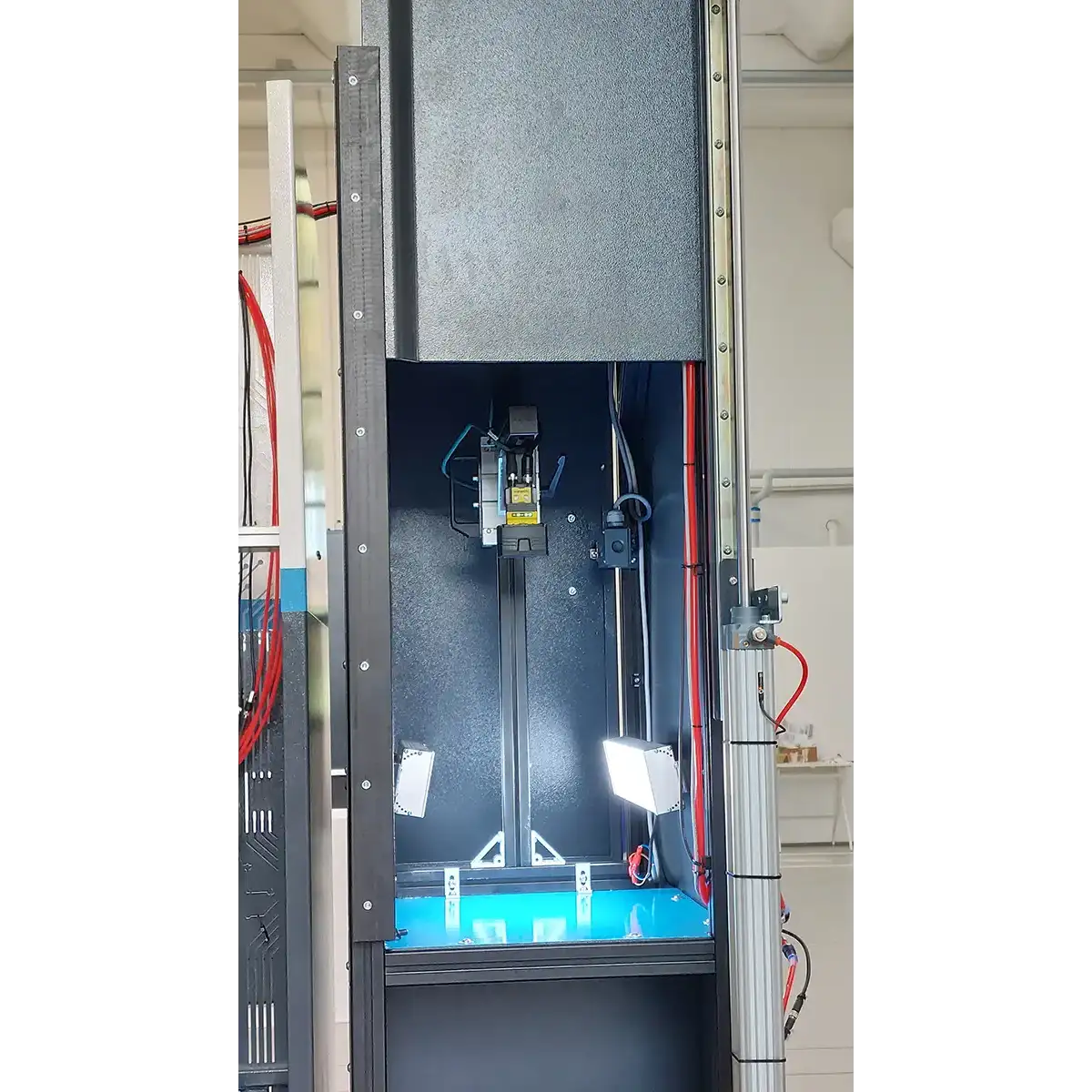

During the feasibility analysis, it became clear that our standard RoboFeed A20 model fell short of meeting the customer’s objectives. Consequently, it was decided to customise the robotic cell by adding unique elements.