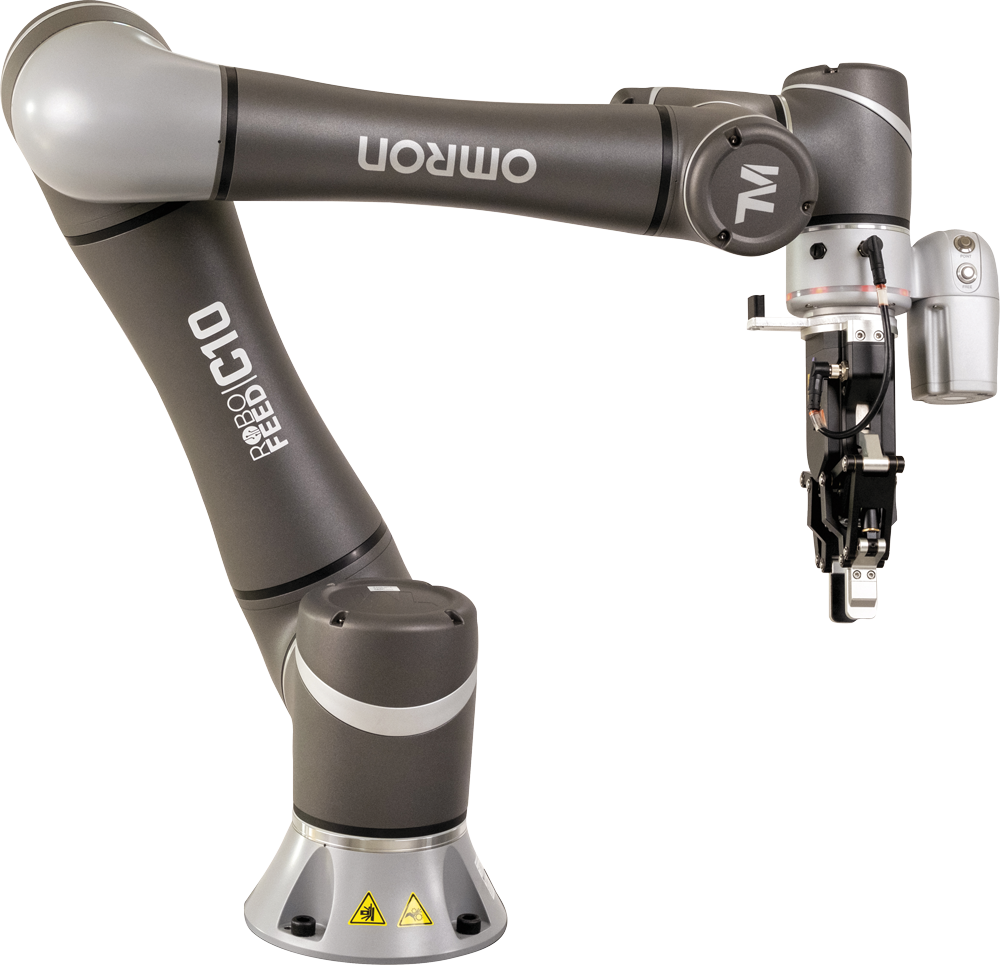

Mobile collaborative robot

for unloading workpieces from the conveyor belt, thus preventing damage.

for unloading workpieces from the conveyor belt, thus preventing damage.

Unloading of the machined parts from the conveyor belt forces the operator to empty the destination drawers in order to prevent dents or other surface damage that generatea significant number of defective and rejected workpieces.

This inevitably leads to increased costs and problems with work schedules.

Systematic tracking of production = rapid detection of nonconformities The parts are stored in blisters housed in the drawers provided, which means that defects are quickly recognised and the problem can be easily resolved. This optimises the production flow and ensures high performance

Unloading of the machined parts from the conveyor belt forces the operator to empty the destination drawers in order to prevent dents or other surface damage that generatea significant number of defective and rejected workpieces.

This inevitably leads to increased costs and problems with work schedules.

Robofeed C10 prevents nonconforming machined parts. The parts are stored in blisters housed in the drawers provided, which means that defects are quickly recognised and the problem can be easily resolved. This optimises the production flow and ensures high performance

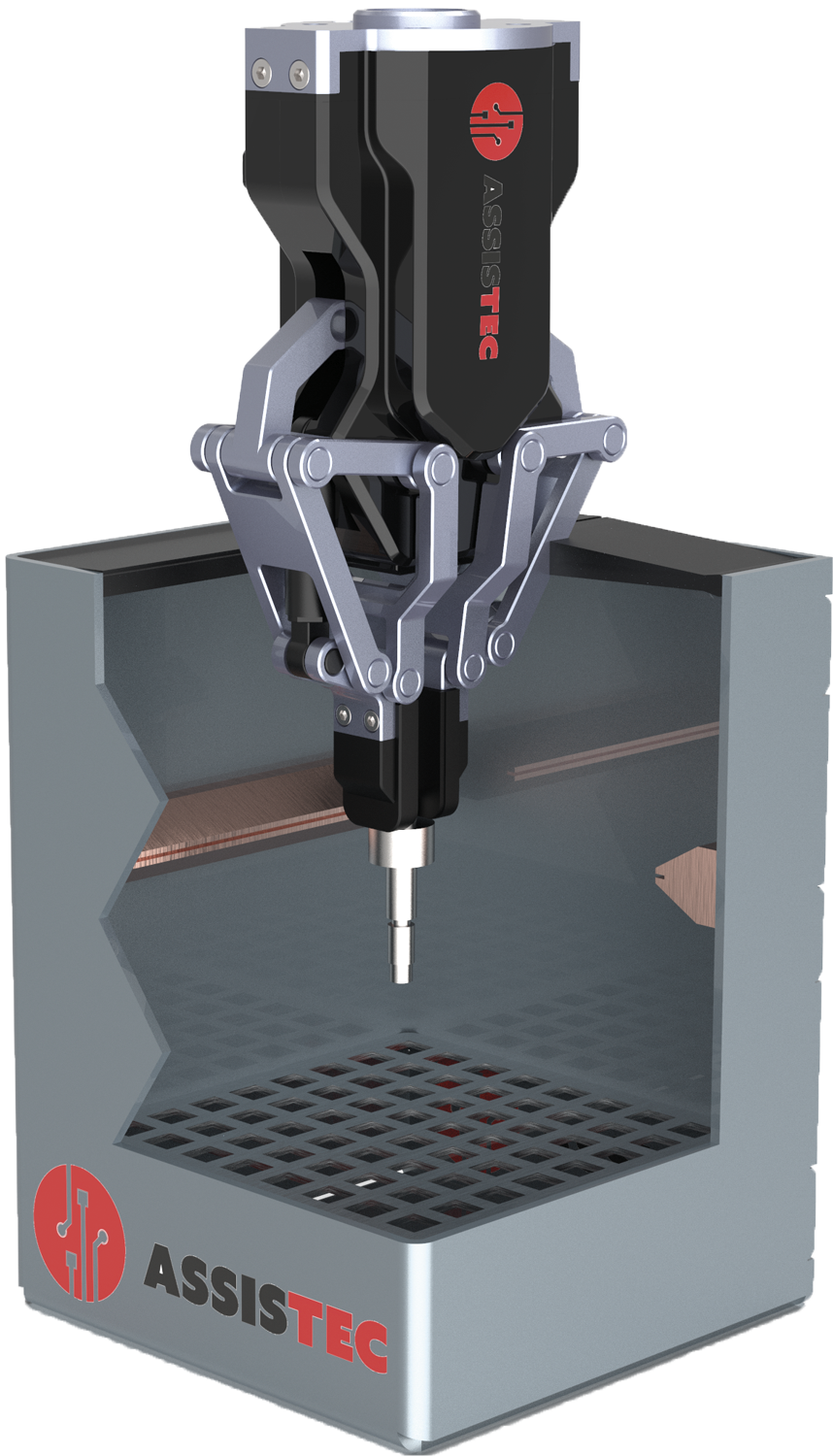

Workpiece storage is fully automatic. The integrated robotic arm places the machine parts in easily extractable drawers, even placing them in blisters.

Systematic production tracking enables rapid detection of defective parts in order to quickly take action to reduce tool wear and breakage.

The optional integrated blowing unit enables chips and oil traces to be effectively removed from workpieces.

(partial/total)

jaws and optional excluded

Assistec and ROI-Calculator by FANUC help you calculate an accurate estimate of the return on investment for automated servicing robots.