As part of our ongoing search for advanced solutions to optimise industrial processes and maximise efficiency, we have entered into a strategic partnership with OnRobot, a leader in cutting-edge workpiece gripping solutions. Let’s explore how OnRobot’s solutions, when combined with our RoboFeed, have brought significant benefits to company seeking to automate their CNC machine tools.

OnRobot's innovative solutions and tools offer unmatched versatility and ease of use, which are revolutionising operations for thousands of companies globally. Among these, three solutions particularly stand out when it comes to workpiece gripping: the 2FG7 electric gripper, the VGC10 electric vacuum gripper, the MG10 electric magnetic gripper and the new 3FG15 flexible three-finger gripper.

The 2FG7 electric parallel gripper is renowned for its flexibility and accuracy, making it perfect for a wide range of industrial applications. Its ease of implementation and programming, without the need for custom designs, ensures a swift return on investment. We integrated this gripper into both our collaborative RoboFeed series C and our RoboFeed A30 and A20 equipped with anthropomorphic robots.

The 2FG7 electric parallel gripper is renowned for its flexibility and accuracy, making it perfect for a wide range of industrial applications. Its ease of implementation and programming, without the need for custom designs, ensures a swift return on investment.

We integrated this gripper into both our collaborative RoboFeed series C and our RoboFeed A30 and A20 equipped with anthropomorphic robots.

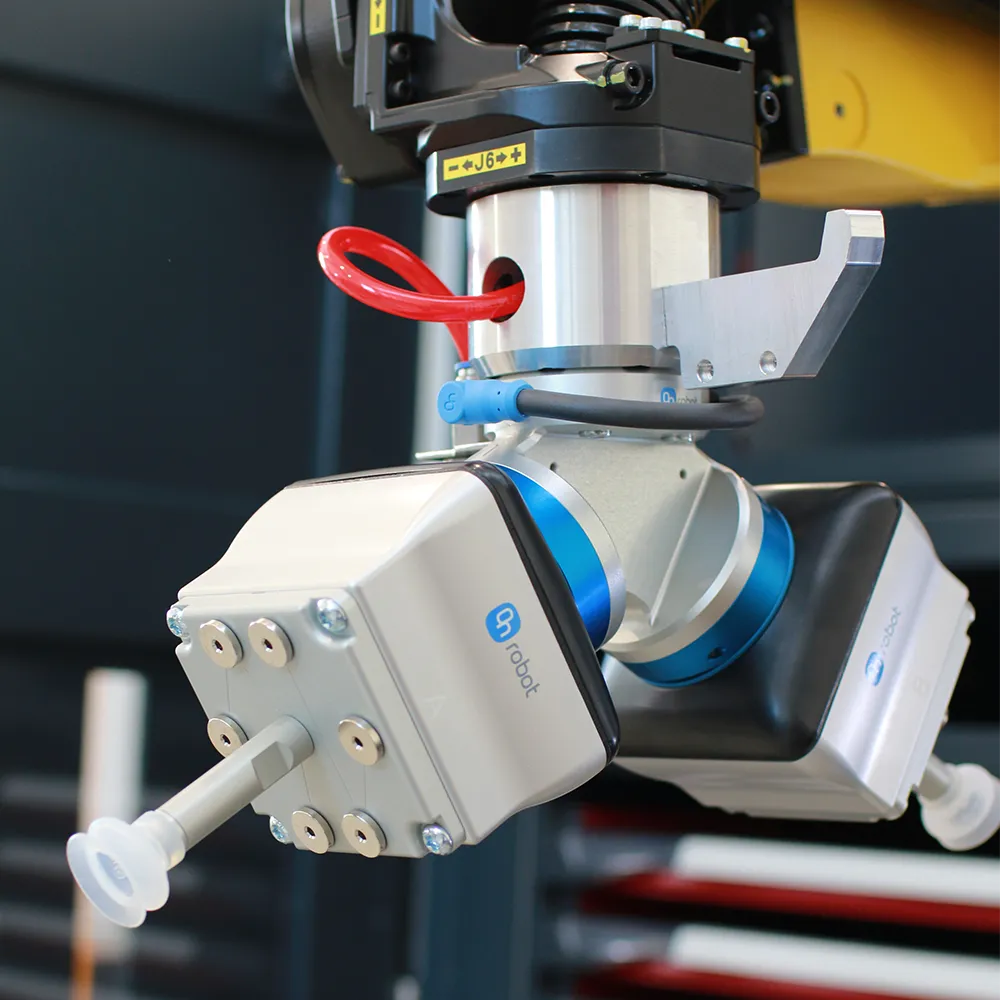

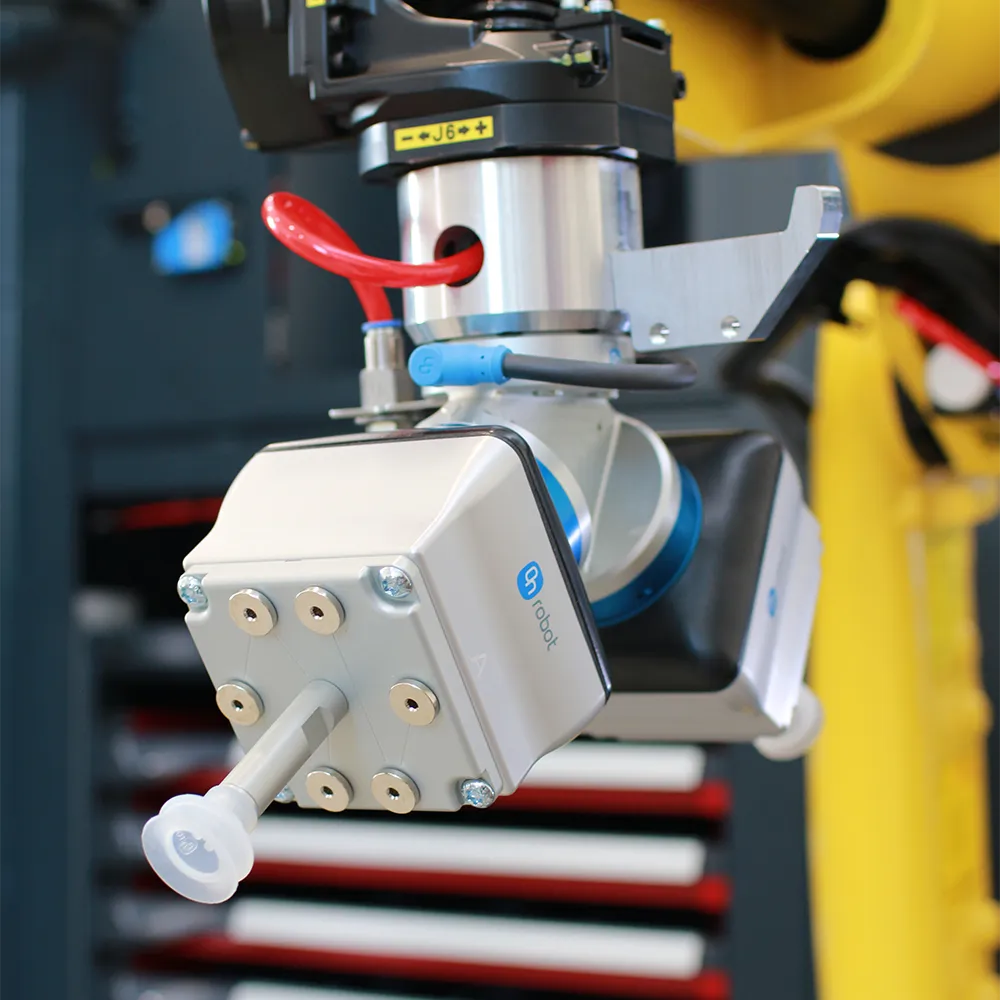

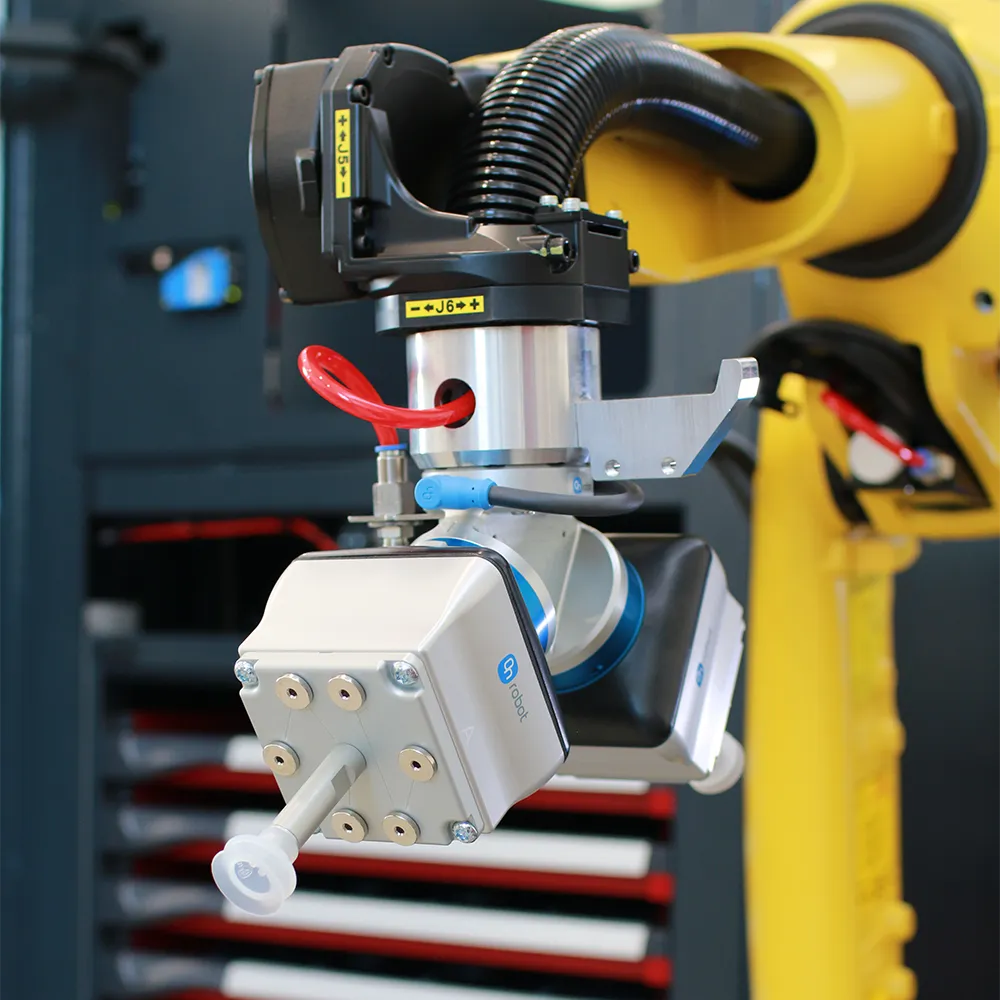

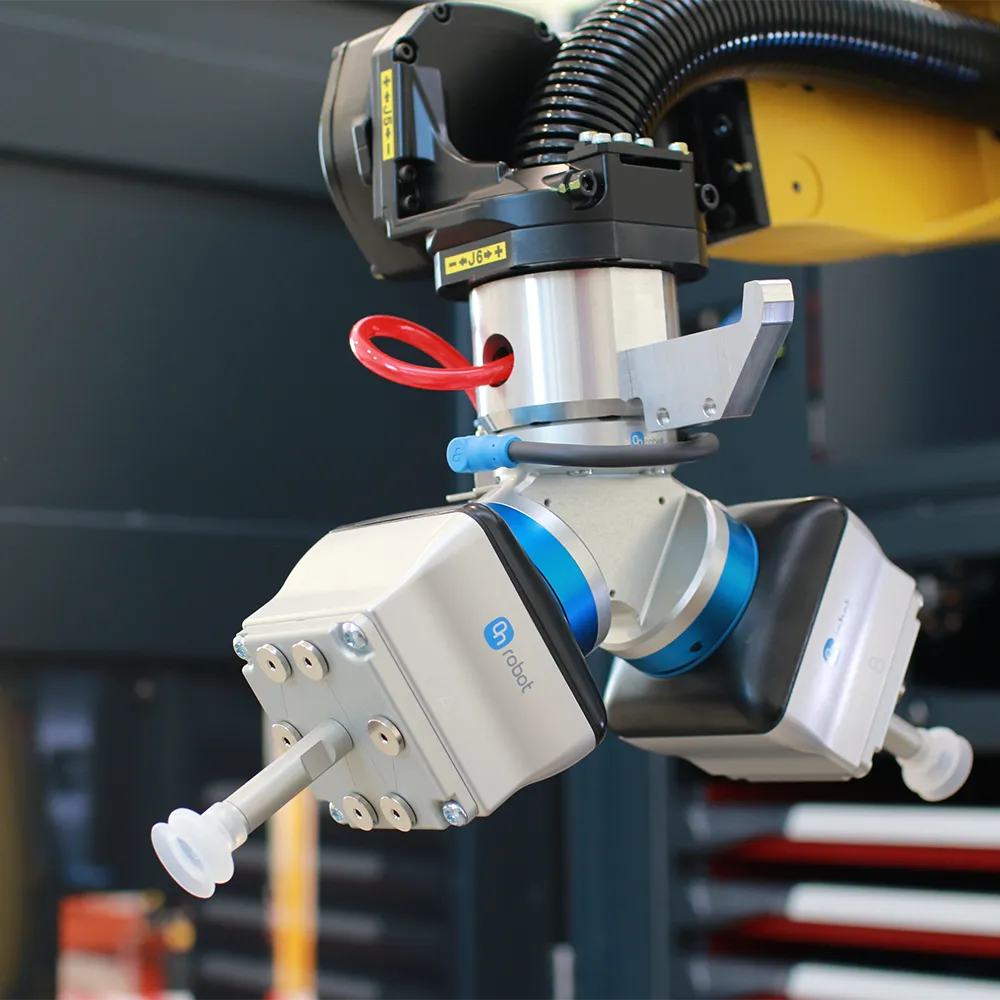

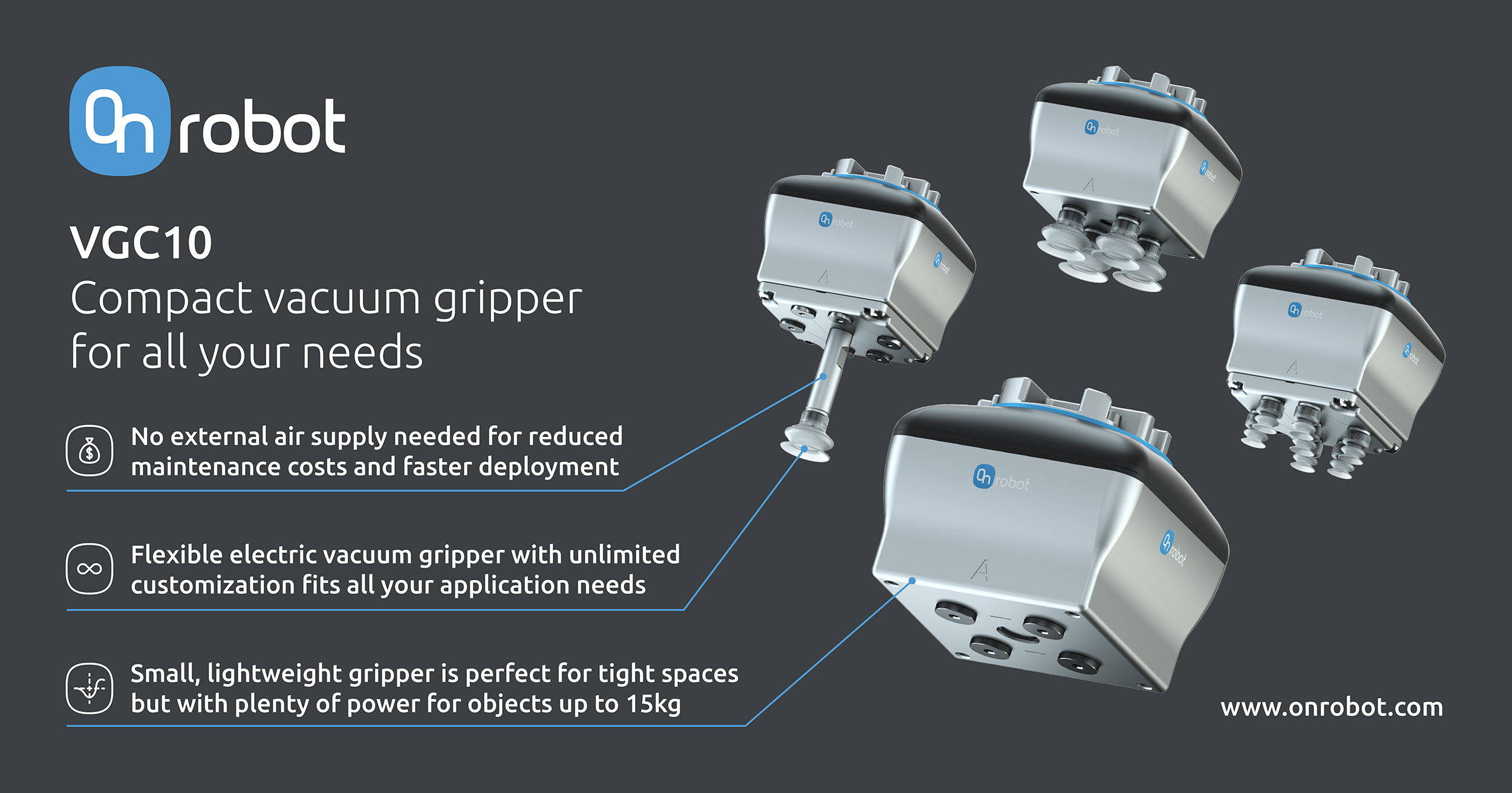

The VGC10 electric vacuum gripper stands out as a compact and flexible solution that can be customised to meet diverse application requirements. Despite its compact and lightweight design, it boasts impressive strength, considering that it can lift up to 15 kilograms.

One of its distinguishing features is that is does not require an external air supply, which simplifies maintenance, cuts down operating costs and accelerates deployment.

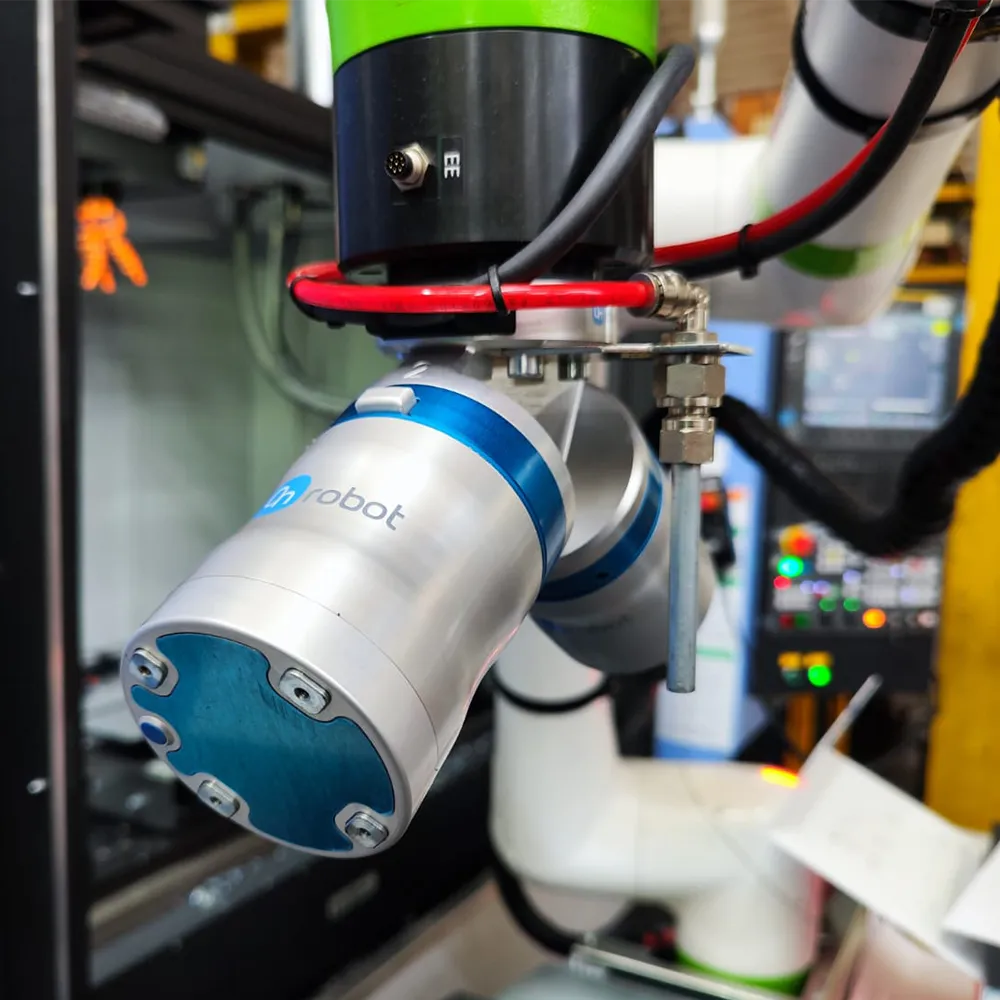

We successfully tested and integrated it into our RoboFeed A20 Custom for our customer, Italtronic. This integration allows transparent plastic parts to be picked up with pinpoint accuracy so that they can be machined with CNC machine tools.

The MG10 electric magnetic gripper is a versatile, ready-to-use solution capable of handling a wide variety of applications in terms of material movement, assembly and machine servicing.

With built-in intelligence, the MG10 adjusts its force for reliable workpiece handling, maintaining the grip even in critical situations, such as when power is lost.

Customisable and adaptable, it suits a wide range of applications, while its built-in proximity sensor detects the presence of irregularly shaped workpieces or those on large flat metal sheets. Particularly suited for pressing and bending applications.

It is integrated with our RoboFeed C20 for processing flat blades, ensuring excellent results without causing any damage to the materials.

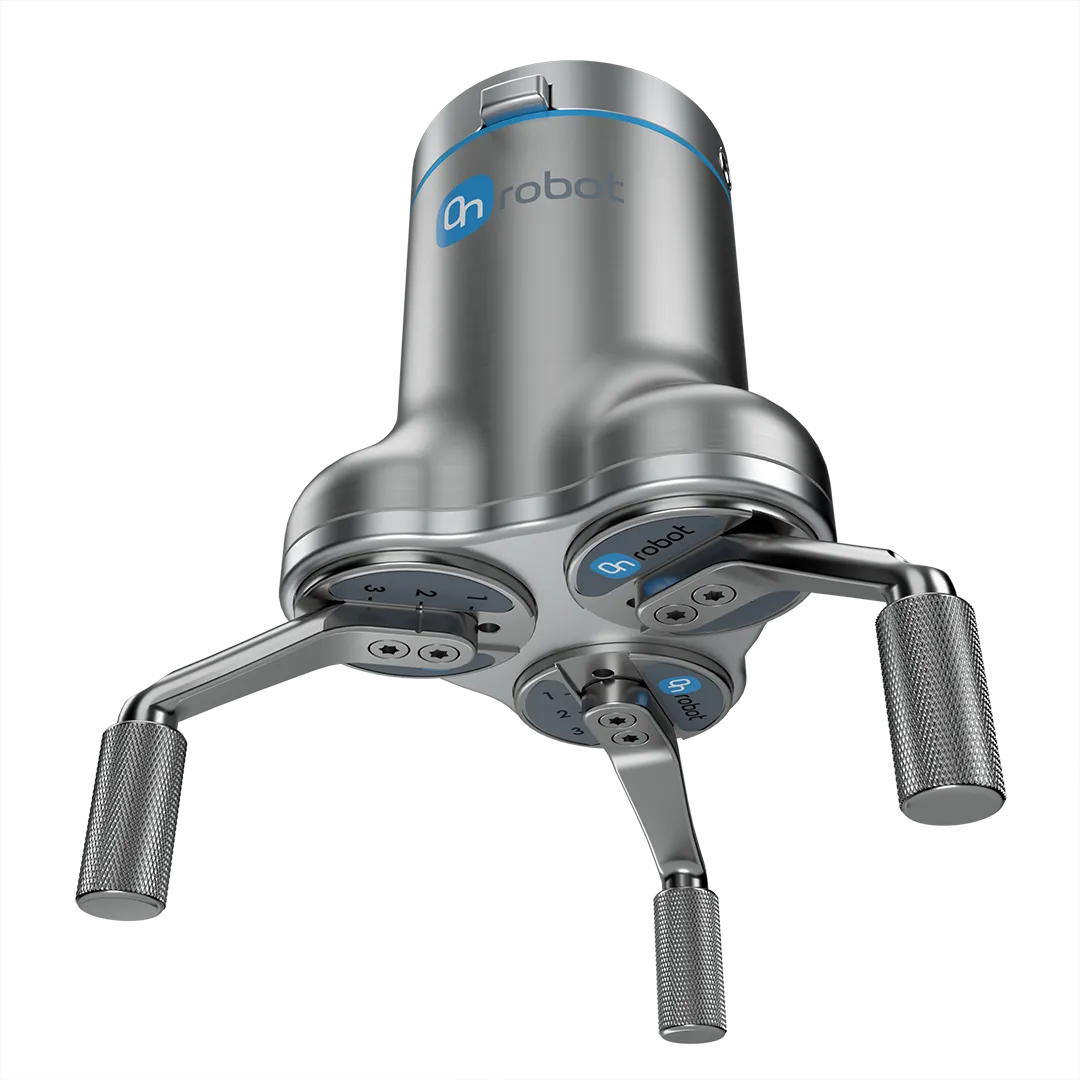

The 3FG15 flexible three-finger gripper offers numerous advantages for optimising machining on CNC lathes. Thanks to its versatile design, it can handle a wide range of cylindrical workpieces of varying sizes (20 to 150 mm) with a single gripper, greatly simplifying production processes.

The main advantages include: