Bin Picking was developed to solve a number of problems faced by our customers, such as palletising workpieces, reducing the physical effort required by the operator when loading and unloading machine tools, and reducing handling times.

When the first Bin Picking solutions were created, we encountered a mathematical and physical problem typical of robotics and vision, which was overcome only with the introduction of 3D vision, coupled with an anthropomorphic robot. Initially, 3D vision was achieved by means of a fairly rudimentary laser scan, which scrolled on a linear axis of the vision system to reconstruct the data. The technological progress over the last 15 years has enabled what was previously considered a mathematical problem to become a technology accessible to everyone and ready to use.

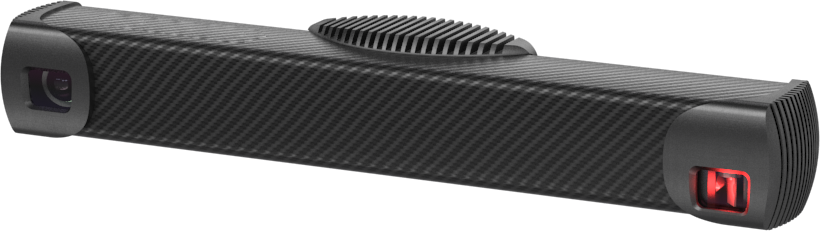

The introduction of 3D sensors has made it possible, without moving the parts, to capture a very precise 3D image of the acquired volume. This technology allows improved performance both in terms of the speed of the operation itself and with regard to grip.

The greater calculation speed of the on-board computers that predict all robot trajectories and movements.

The evolution of software in recent years.

When a very large object to be picked from a small crate, we speak of a simple application. When, on the other hand, a small object is to be picked from a very large crate, we speak of a more complex application, as a higher degree of repeatability and accuracy is required.

In our show room we have set up an example of Bin Picking of a piece of raw sheet metal measuring 90x80x3 mm for the purpose of palletising parts.

As there may normally be thousands of parts inside the bin, the degree of complexity we had to deal with was quite high.

Data la difficoltà medio alta dell’applicazione è stato scelto un sensore 3D tecnologicamente molto avanzato che consente di avere un’accuratezza e una velocità notevole sul dato. The robot chosen, on the other hand, is a Fanuc M 10 iD – 12, which allows an extremely high performance in terms of speed and a minimal footprint, favouring a completely agile entry into the bin without any type of obstacle.

Based on the type of product and customer requirements, a preliminary feasibility check is carried out. This initial analysis enables us to provide the customer with a series of data that are indispensable for formulating the choice: feasibility outcome, cycle times, bin emptying rate, type of robot and gripper systems, cell layout and many other useful data. In addition to a simulation aimed at the required specifications, it enables the operator to see a working application at any time.

The Bin Picking system project was developed with the support of the European Union and other funding bodies such as:

In addition to the technological benefits, the salient improvements at the Human Centric level are: