CMO , one of the leading companies in the field of hydraulic equipment, decided to integrate a robot cell into its machine park to increase market competitiveness and improve production efficiency. However, the island installed by a third-party integrator was not working properly, presenting significant malfunctions.

The cell, which was installed three years ago, has never been able to function in unmanned mode.

It consists of the following elements:

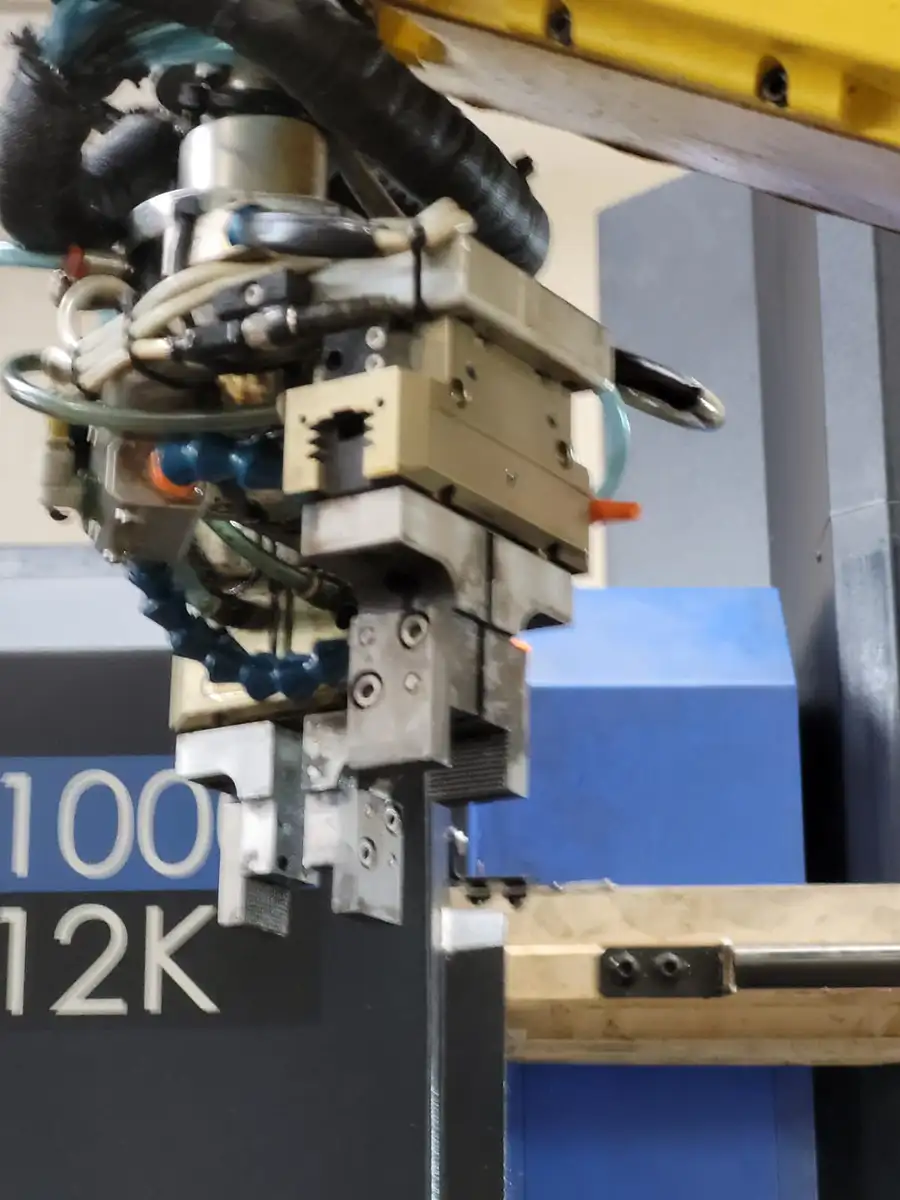

- a robot on a pedestal;

- a CNC machine tool;

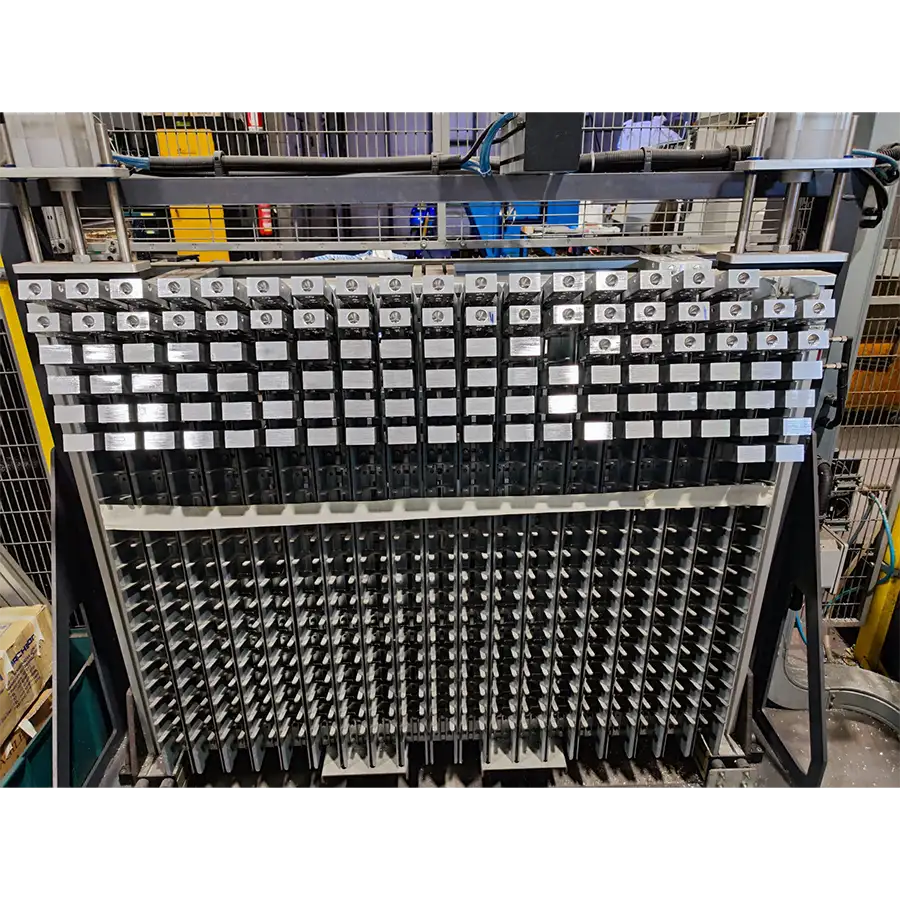

- rack magazine installed on a rotary table for loading blanks in masked time

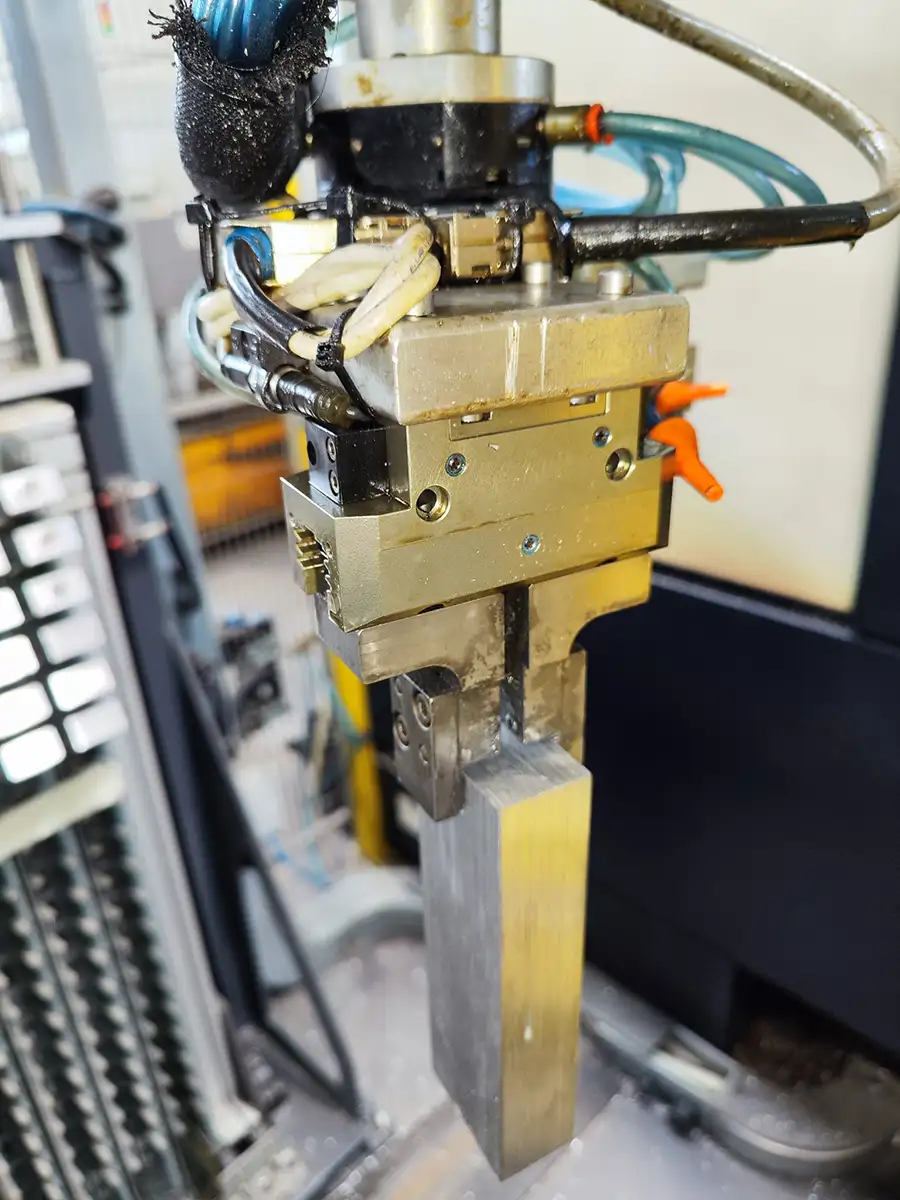

- Retraining station for correct workpiece pick-up.

- Workpiece washing station: workpiece washing after machining to remove impurities left over from machining.

After a discussion with the customer, it was decided to take action on the problems highlighted without redesigning the island due to the costly investment.