COLLABORATIVE ROBOT SOLUTIONS FOR MOBILITY AND PRODUCTION FLEXIBILITY

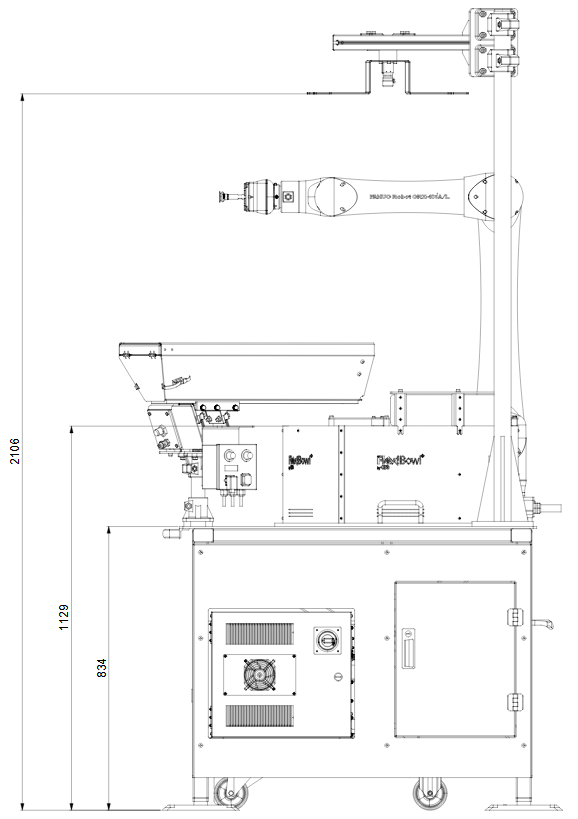

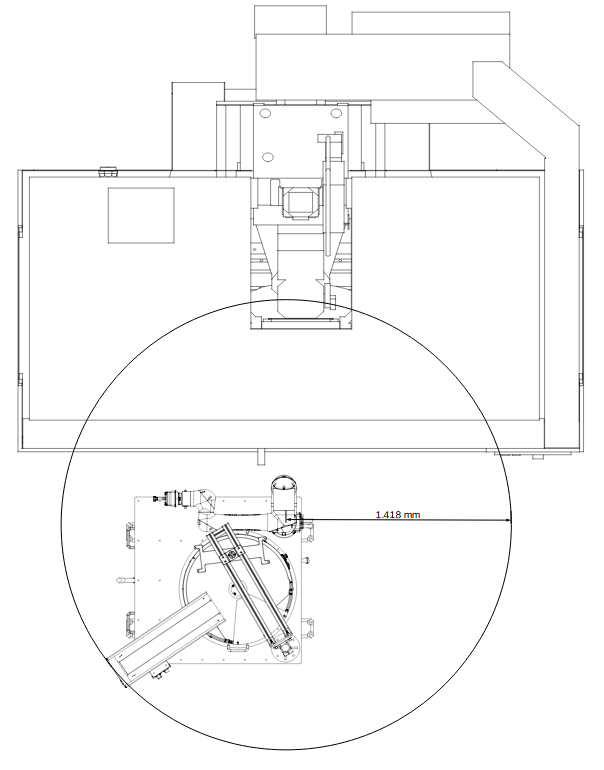

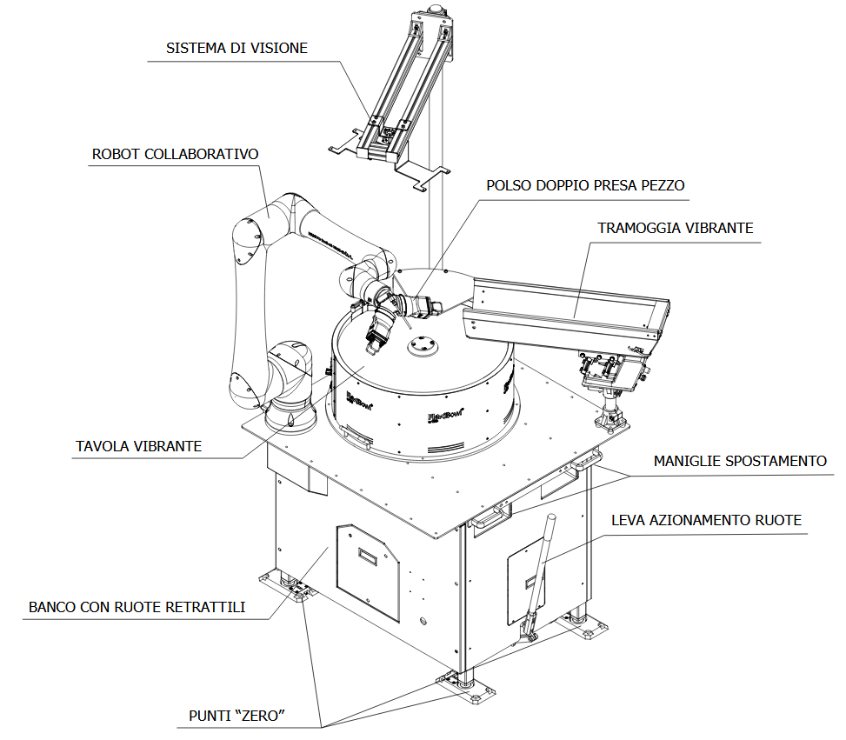

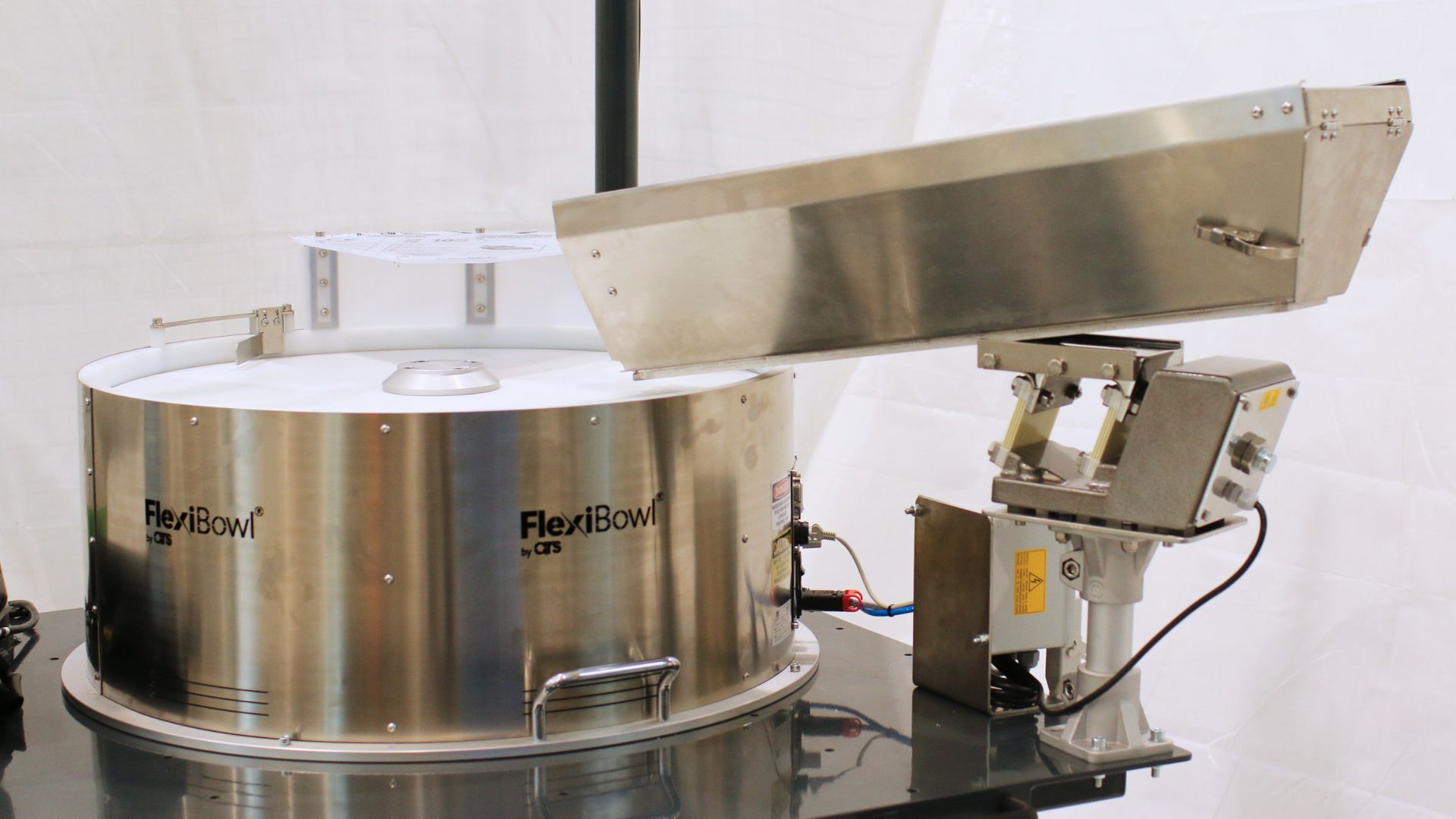

ROBO FEED CX is the collaborative robotics solution from Assistec, designed to provide an automated robotic feeding and handling system for small to medium-sized parts.

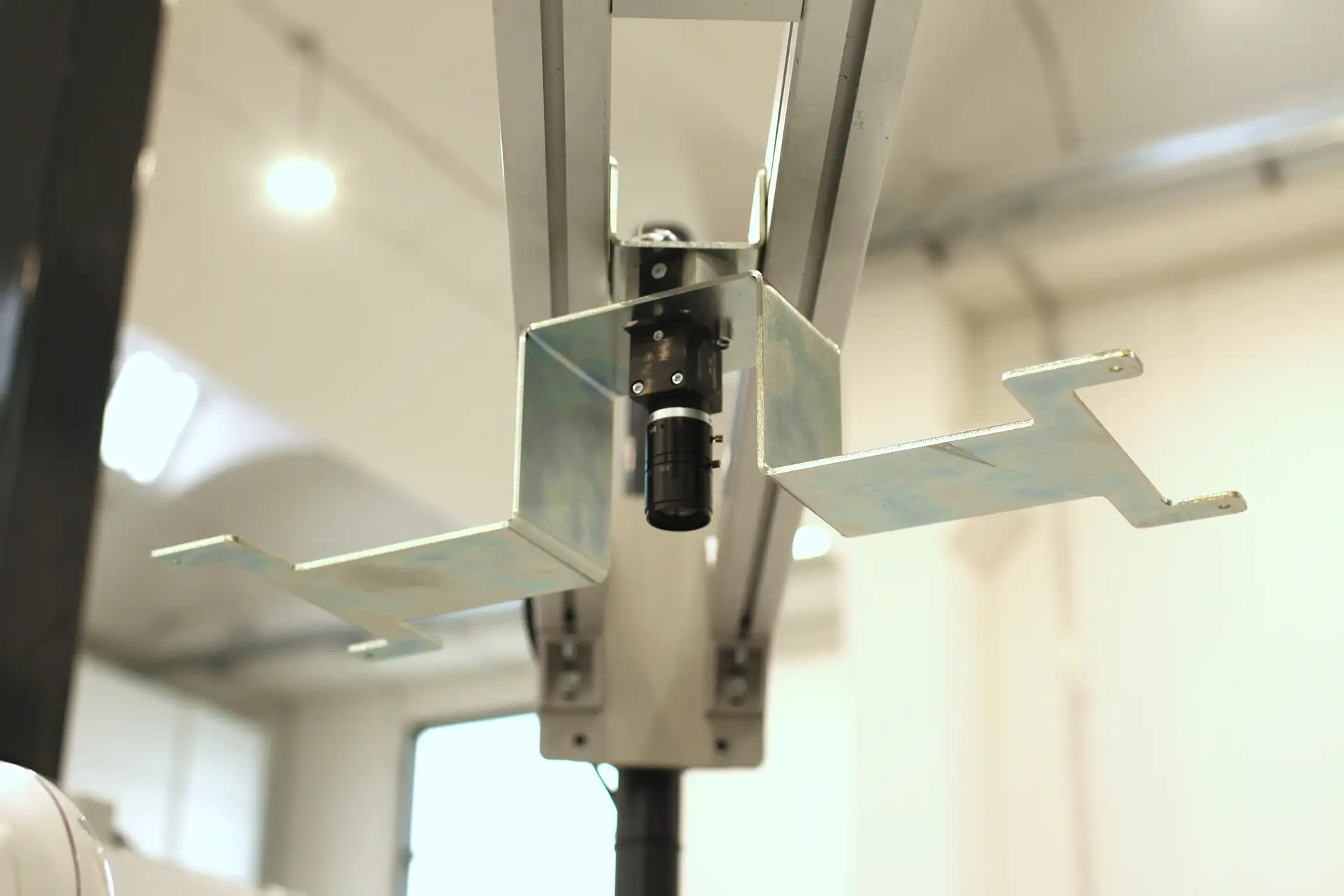

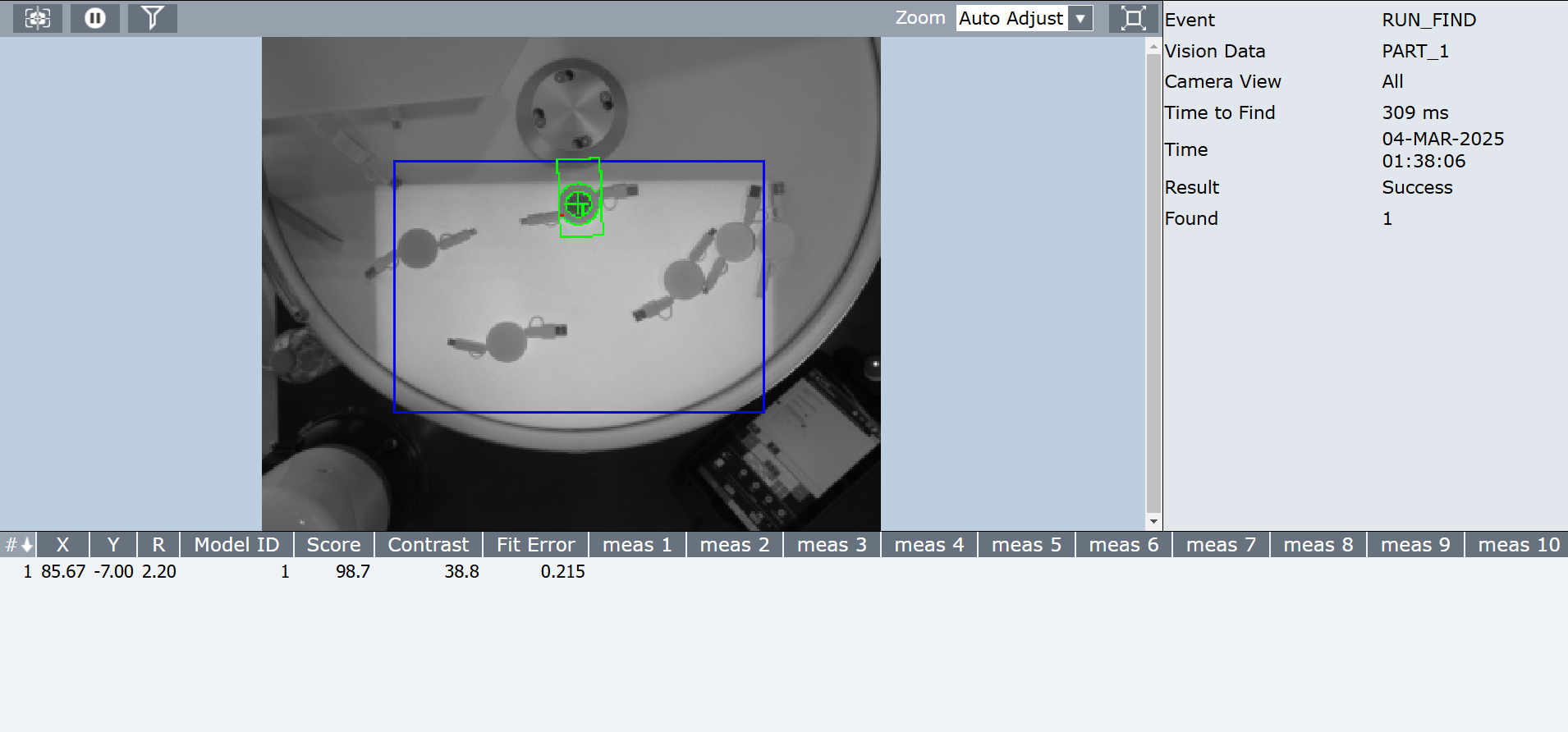

ROBO FEED CX allows parts to be fed, oriented, separated and scanned for fast retrieval by a FANUC CRX10iA/L collaborative robot.

The compact dimensions and absence of bulky structures save space on the shop floor and allow the CNC machine to be used in manual mode, with one operator, as often as necessary.

The software developed by Assistec and the self-learning functions of the Fanuc Cobot reduce programming time and simplify the work of the toolmaker.

(*indicative data to be verified according to the model selected)

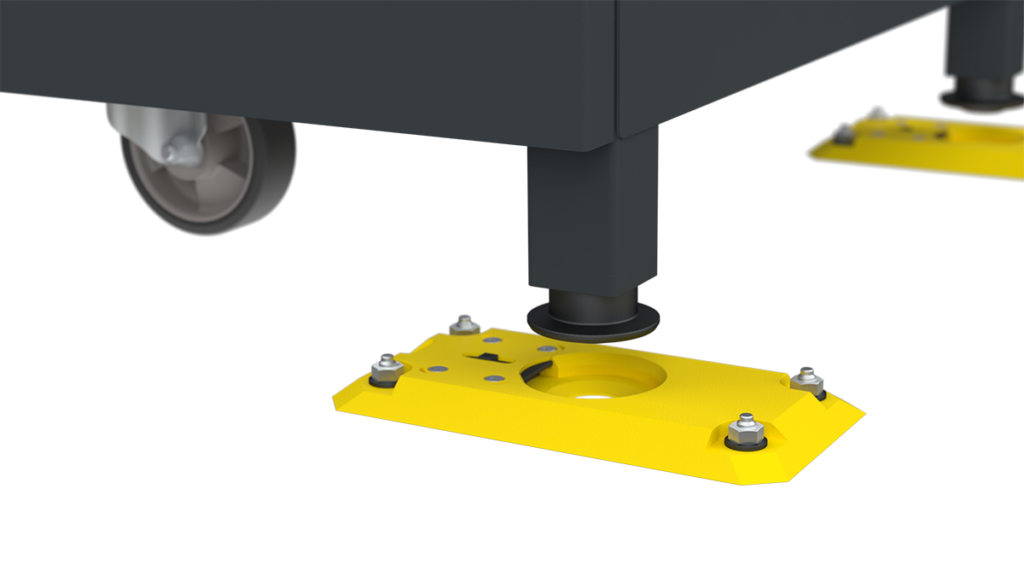

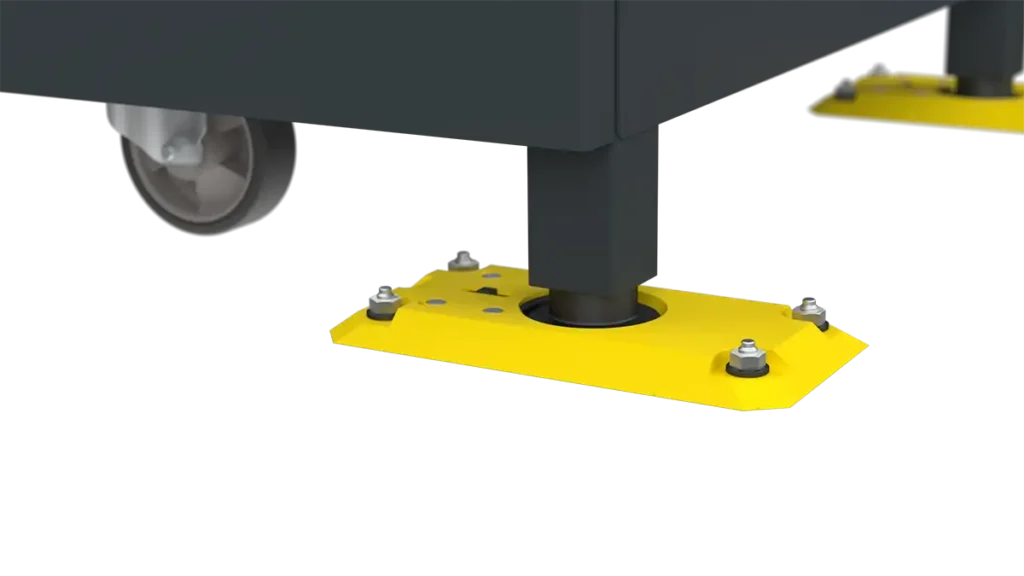

The Electric Lifting System is the solution that simplifies and optimises movements between machine tools, offering concrete advantages for your productivity.

The advantages:

Maximise your production efficiency with Fanuc Cobot and Assistec customised software. Thanks to an intuitive interface, programming becomes immediate and accessible even to less experienced operators..

Manual handling for faster operation.

The operator can move the robotic arm manually, allowing the Cobot to learn the coordinates automatically. This drastically reduces set-up times, improving productivity and process accuracy.

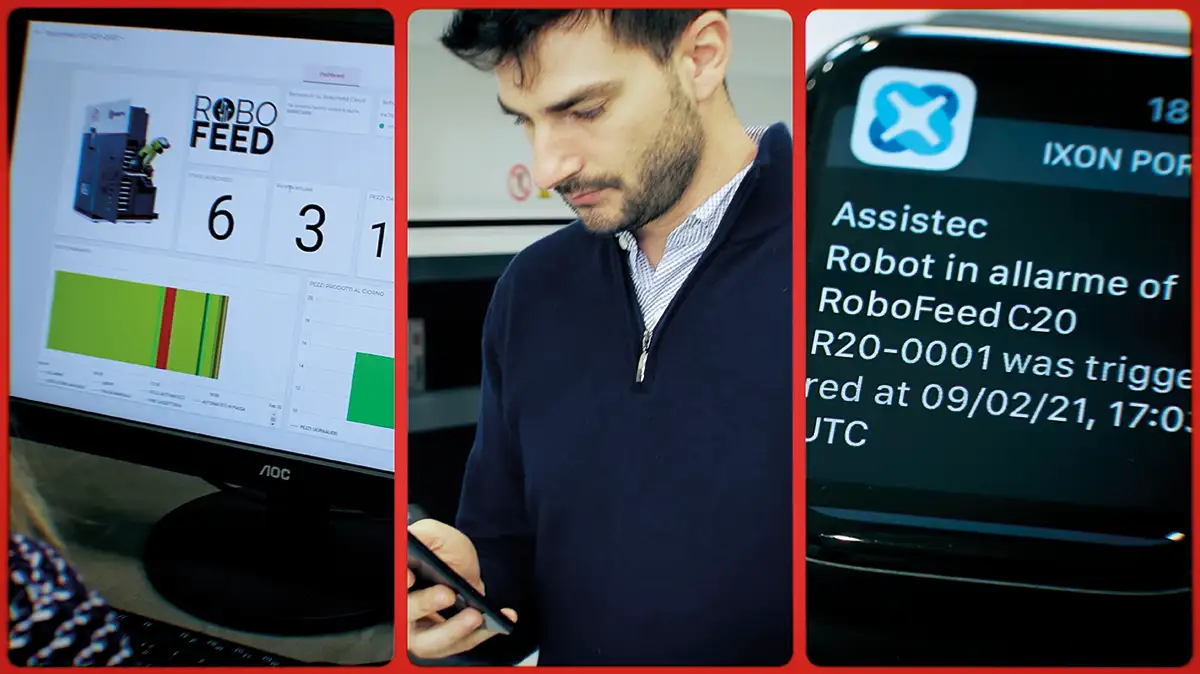

Real-time control with the mobile app

The dedicated app, integrated with the company’s system, provides constant monitoring of machine data, ensuring total control and more efficient management of operations.

.