Zanasi Iuri snc di Alfredo & Iuri Zanasi, a company specialising in the production of metal i parts for various automotive and earthmoving industries, needed a compact automated solution to optimise the loading and unloading process of a STAR D6 3-axis vertical machining centre with a double worktable and Fanuc CNC. The machine was very old, but still efficient and productive.

The main objective was to automate an outdated machine tool and create user-friendly automation for in-house operators who were new to the subject. L’obiettivo principale era di automatizzare una macchina utensile datata e creare un’automazione di facile utilizzo da parte degli operatori interni acerbi in materia.

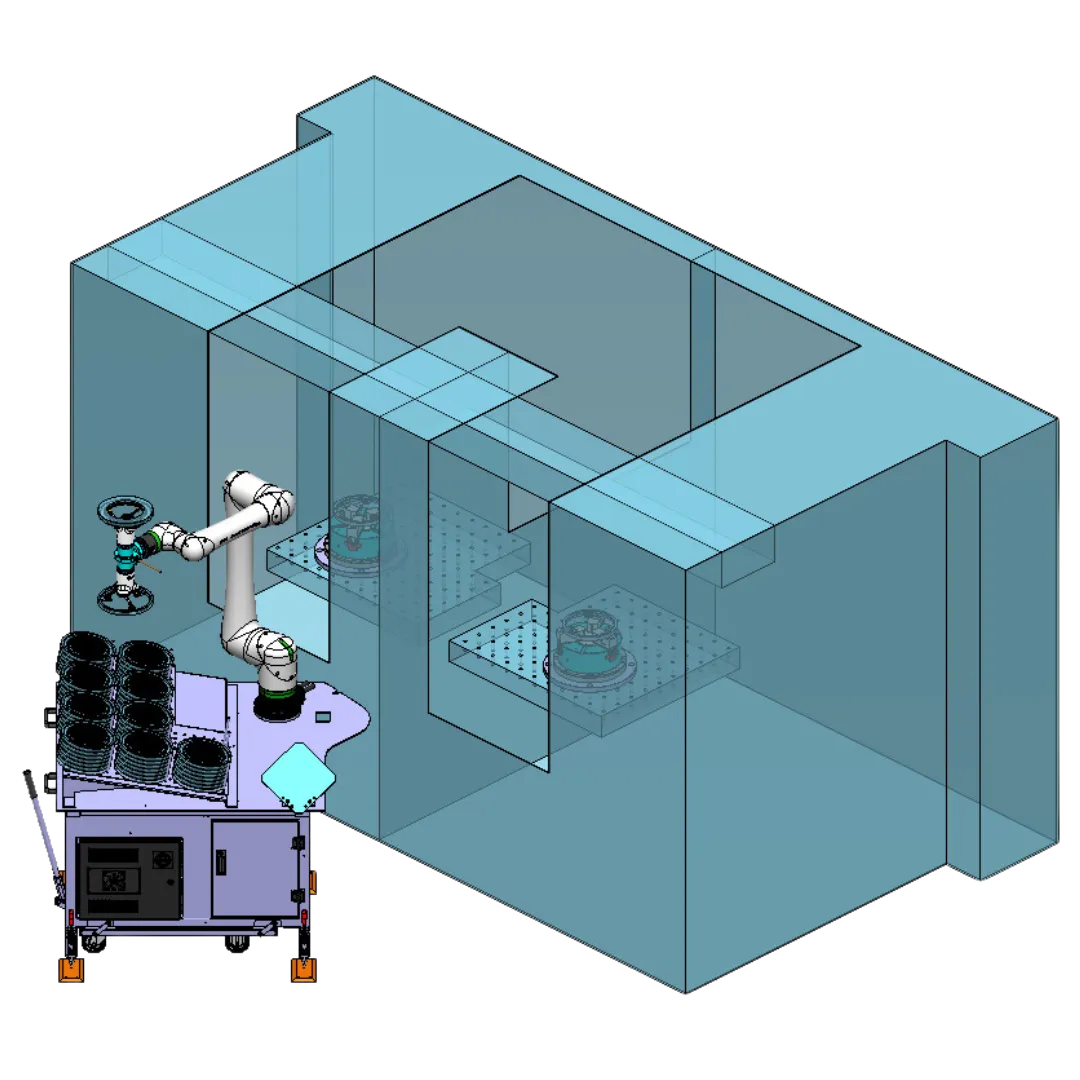

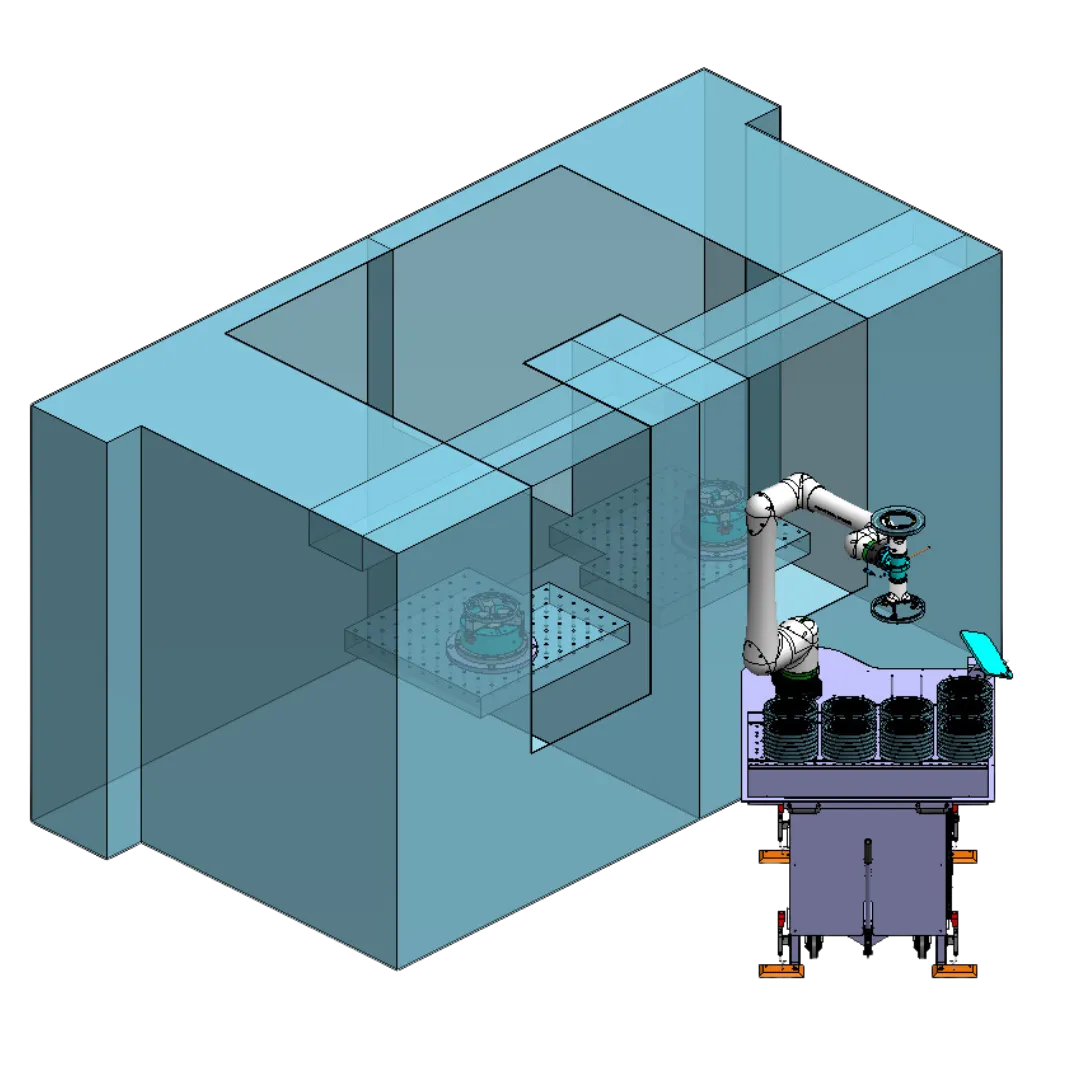

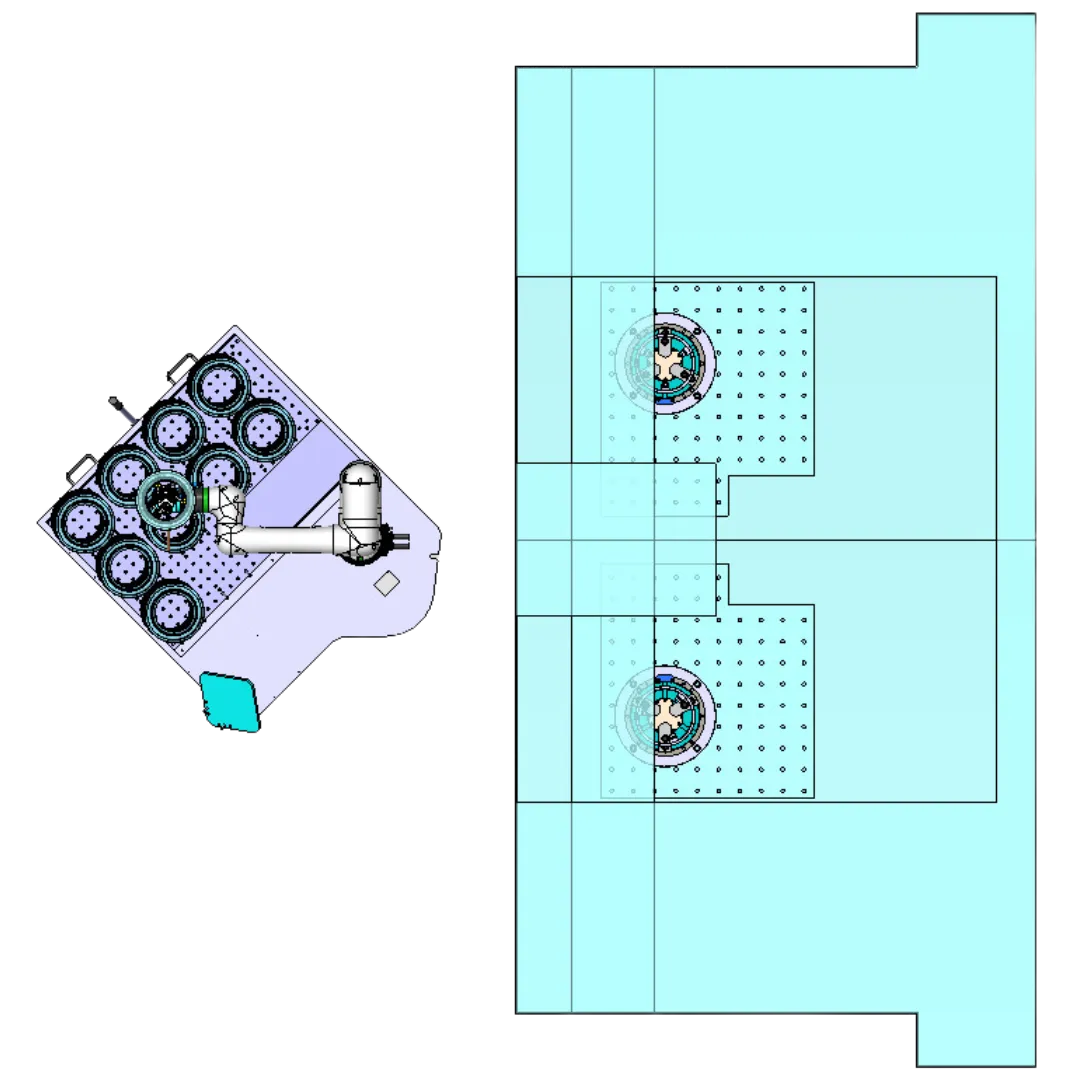

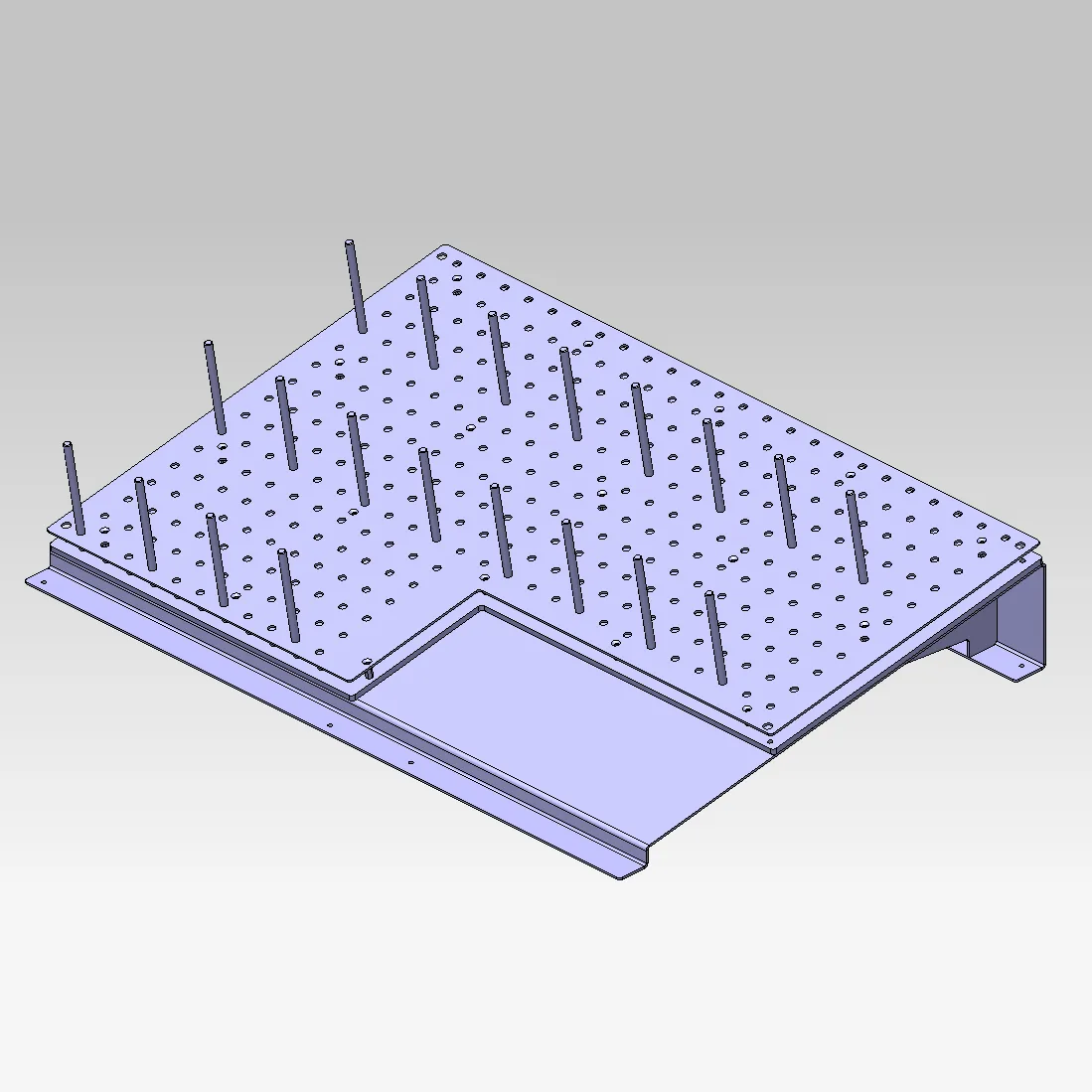

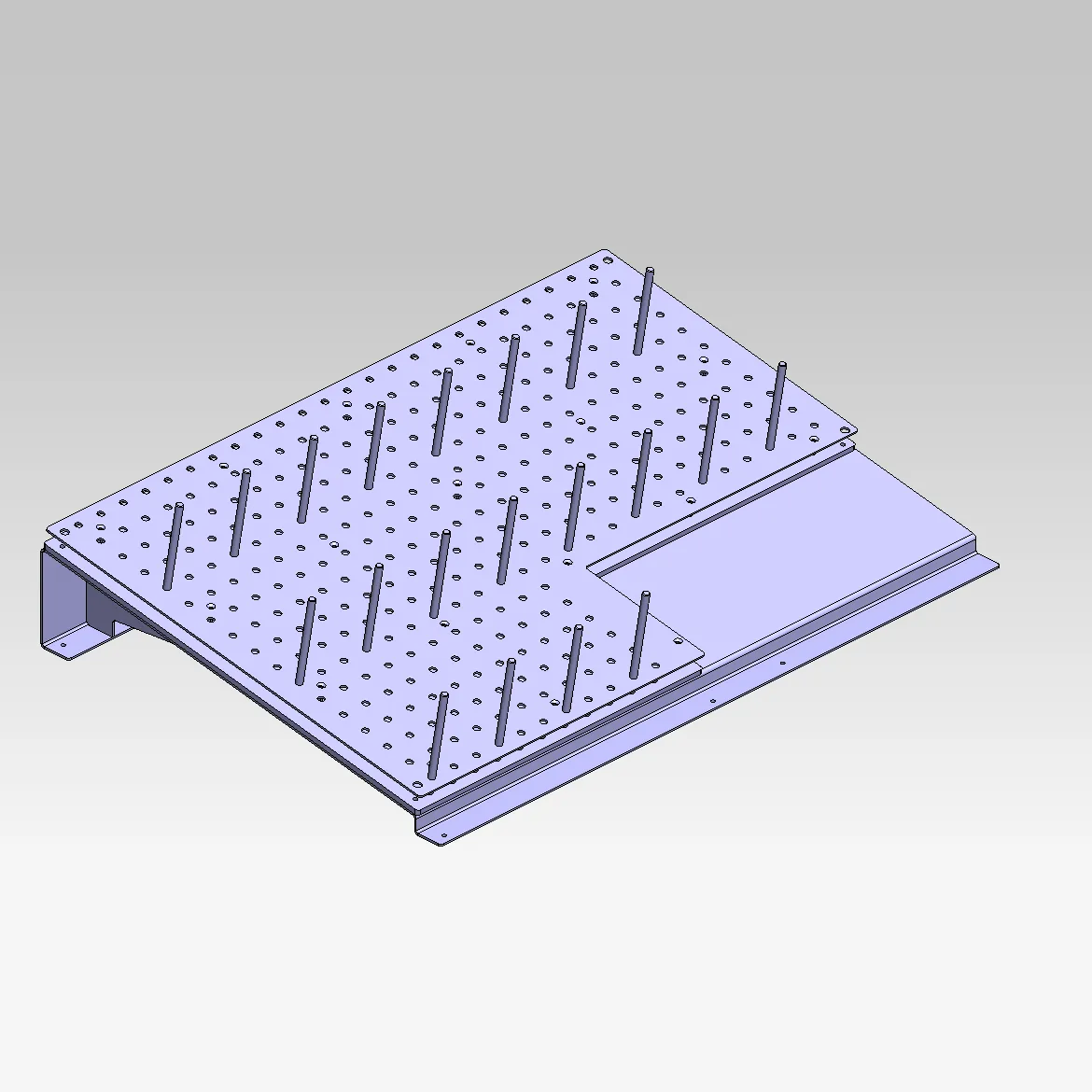

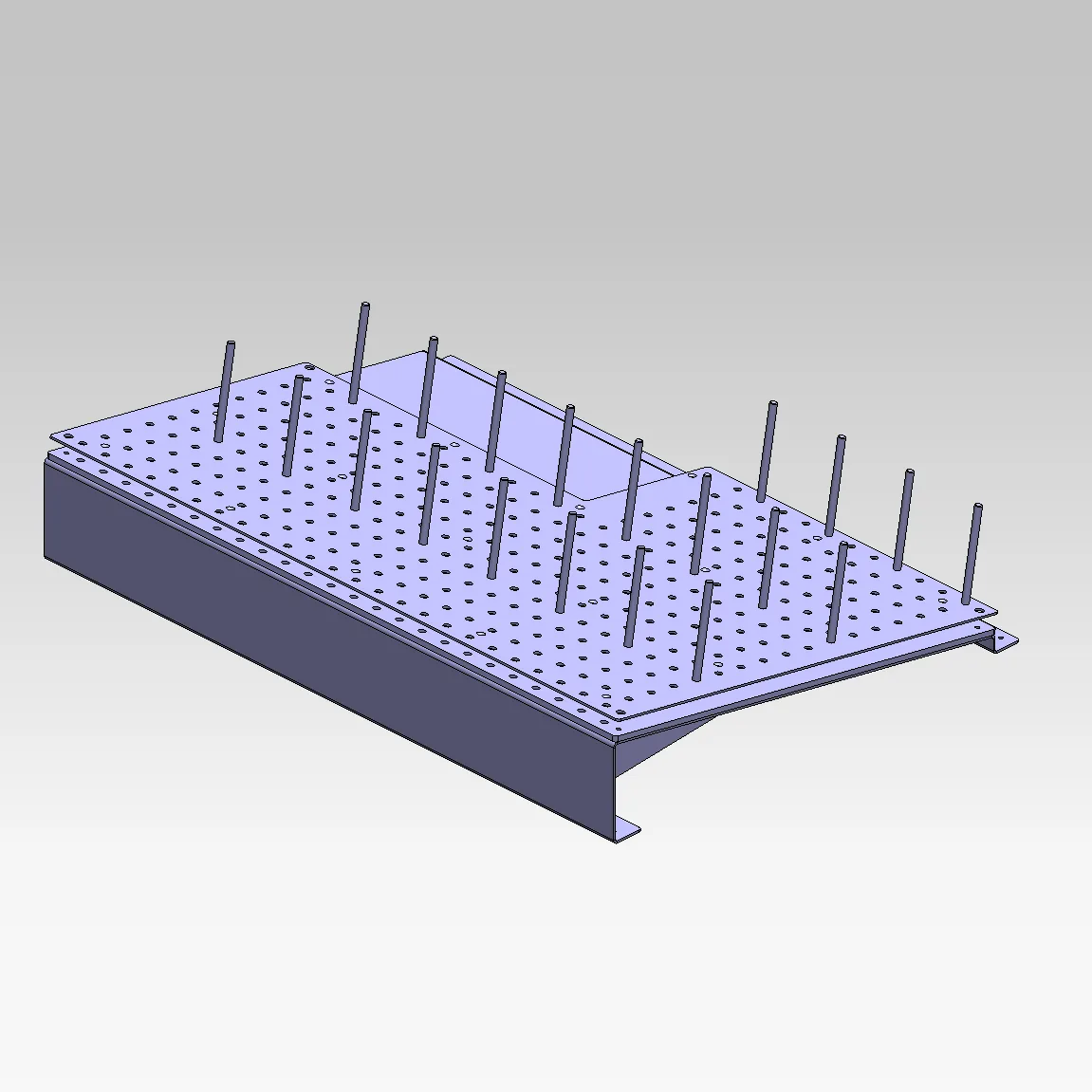

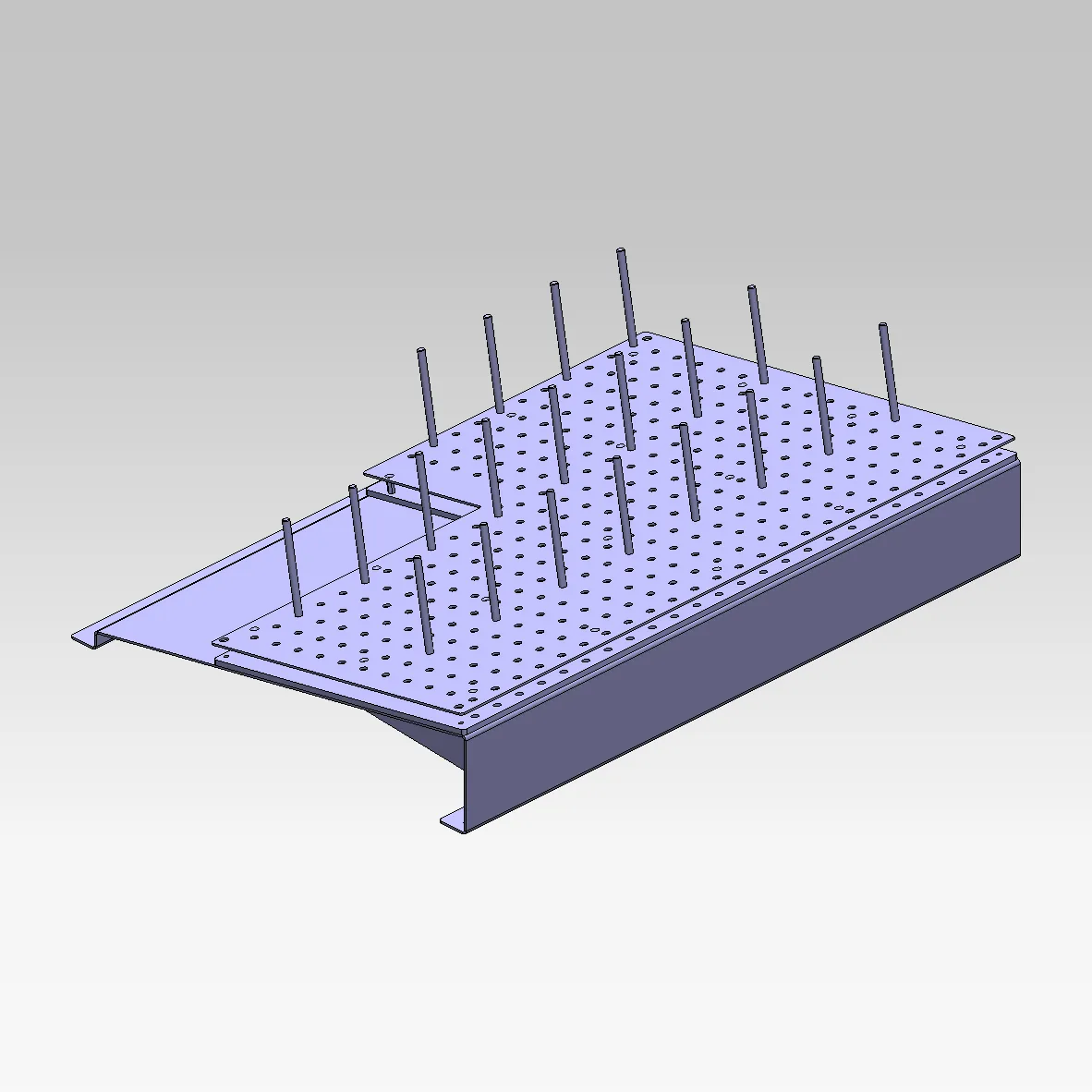

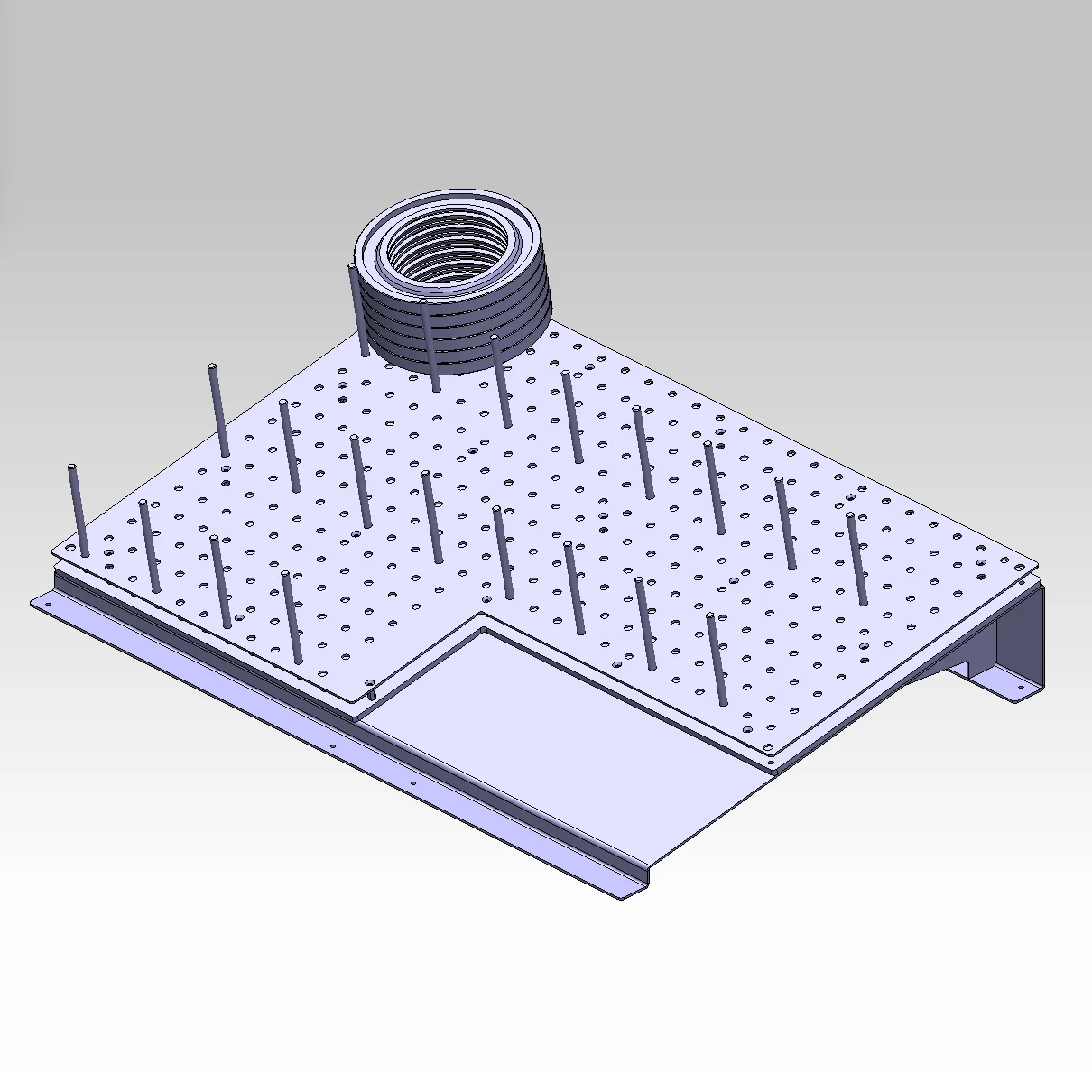

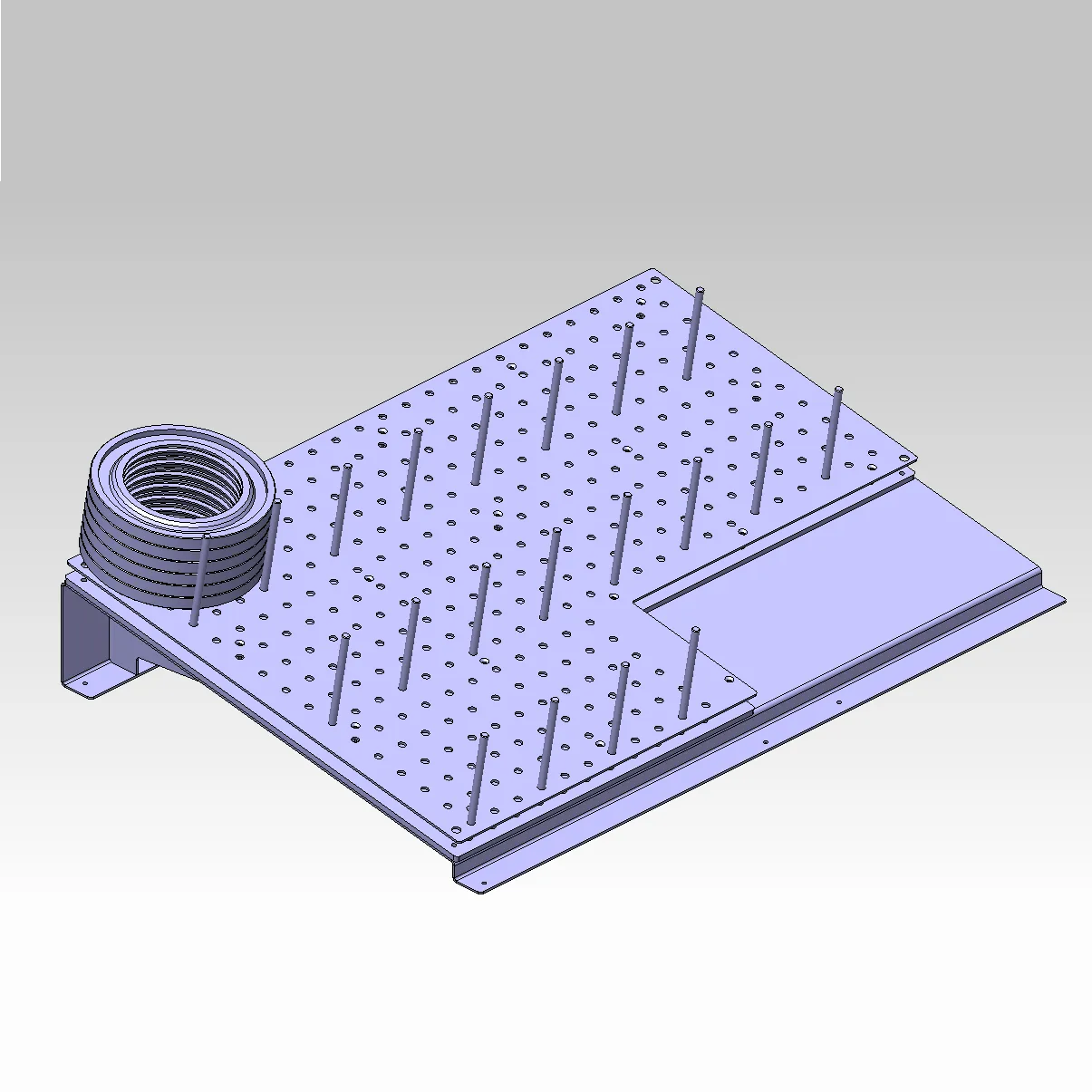

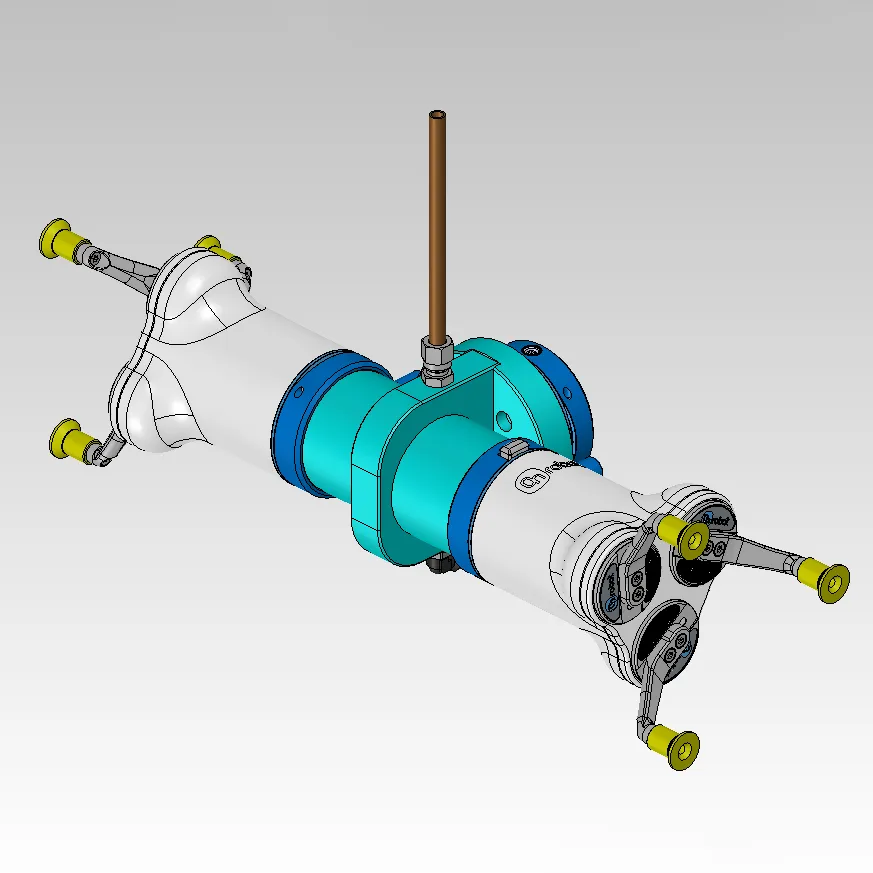

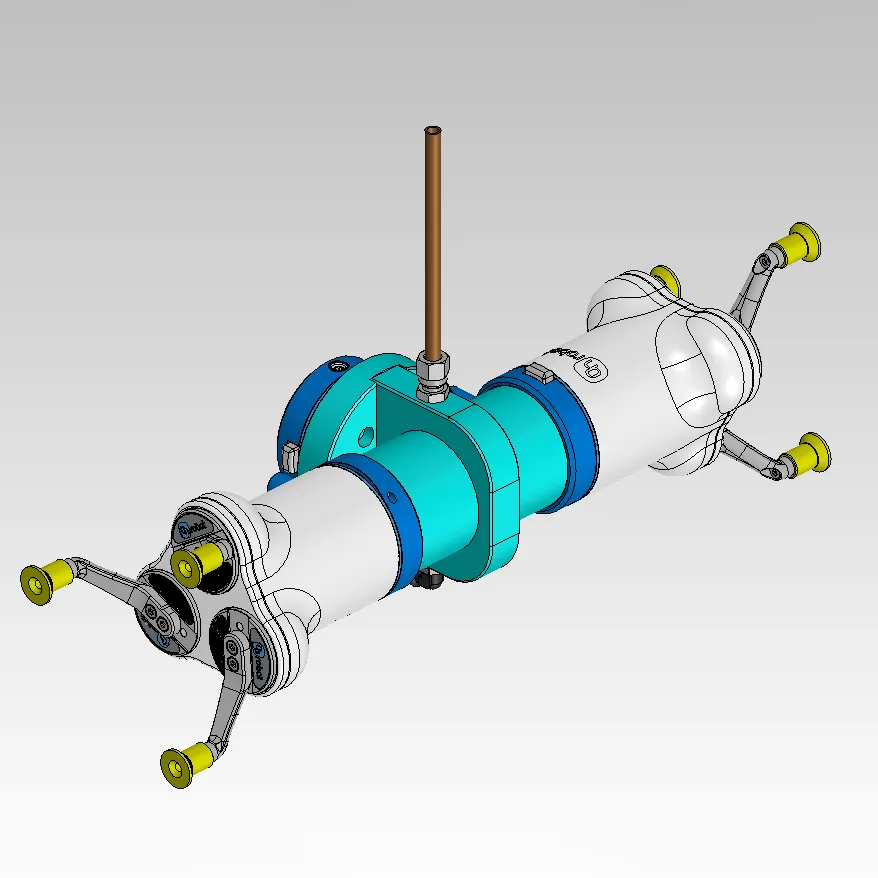

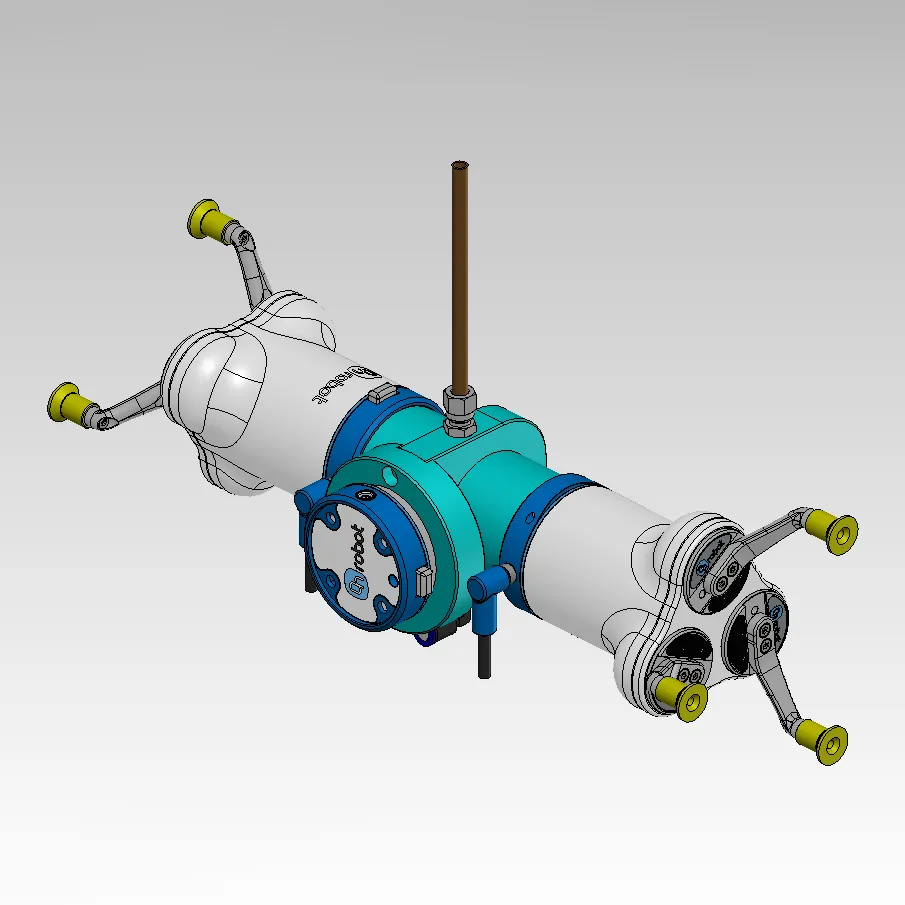

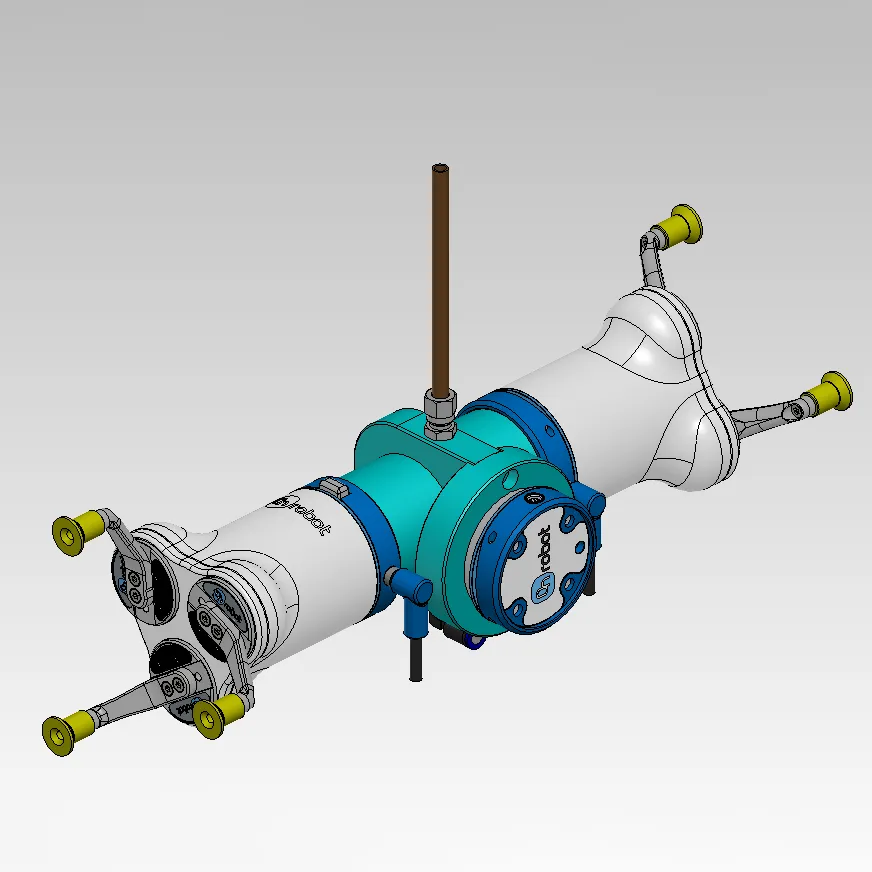

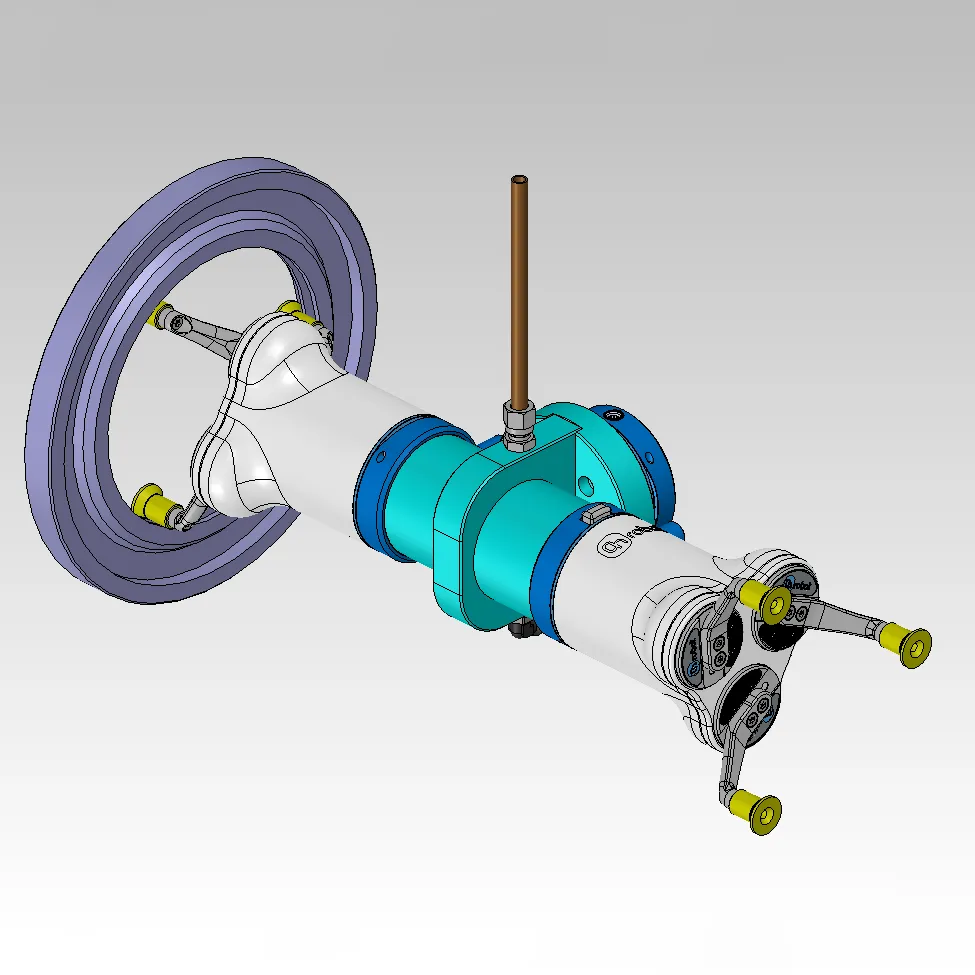

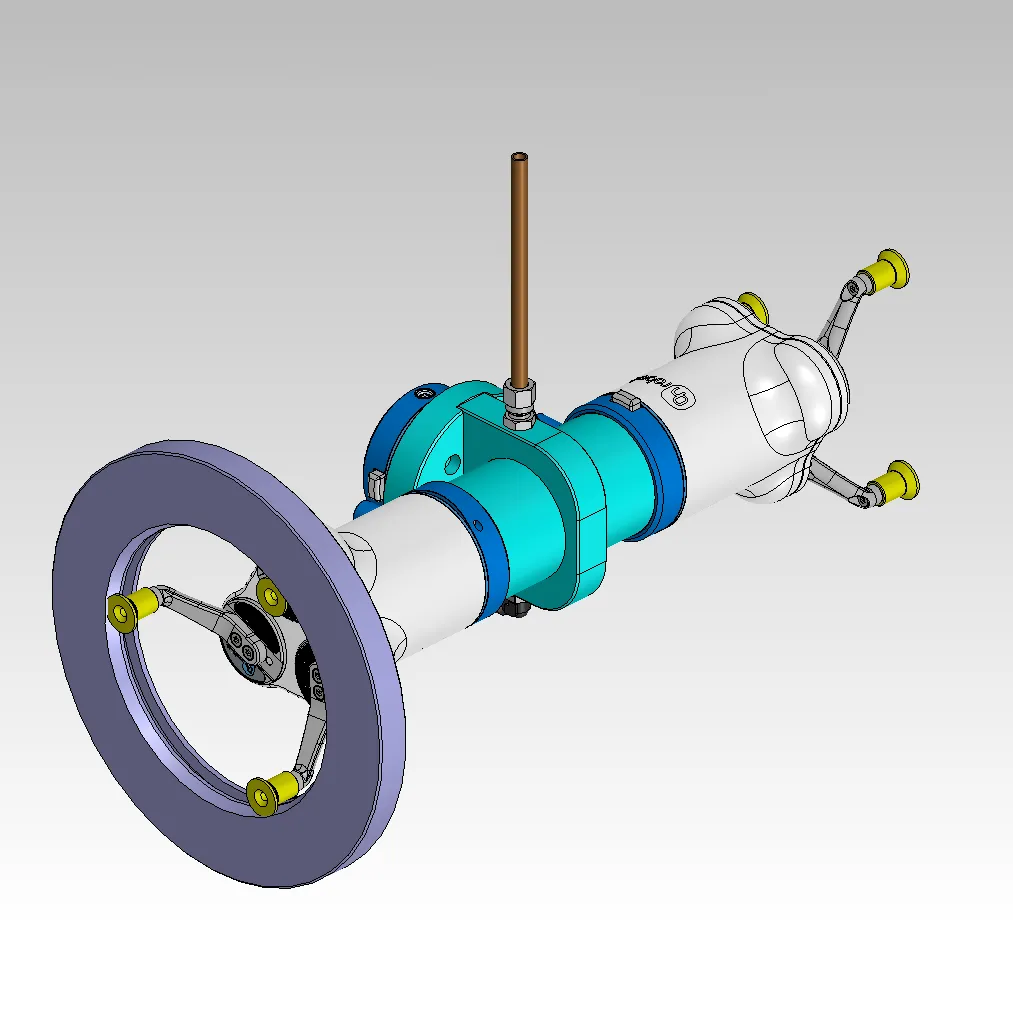

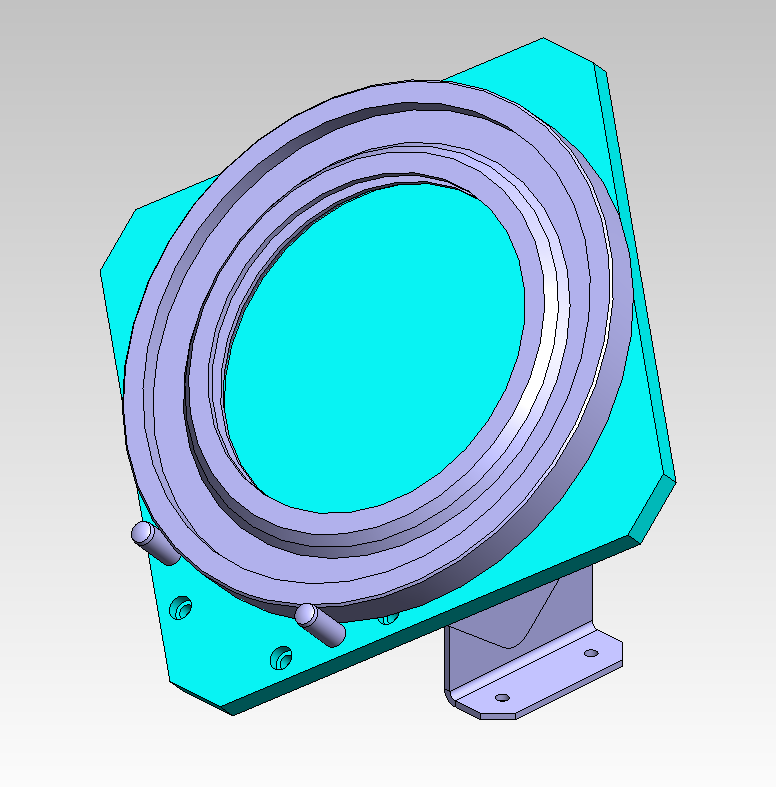

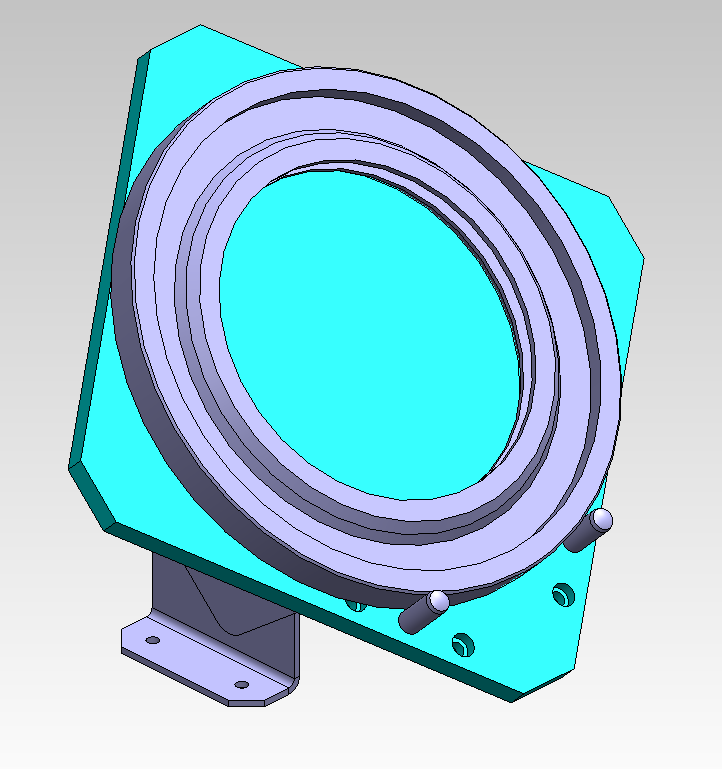

Soluzione: Robo Feed C20 Custom

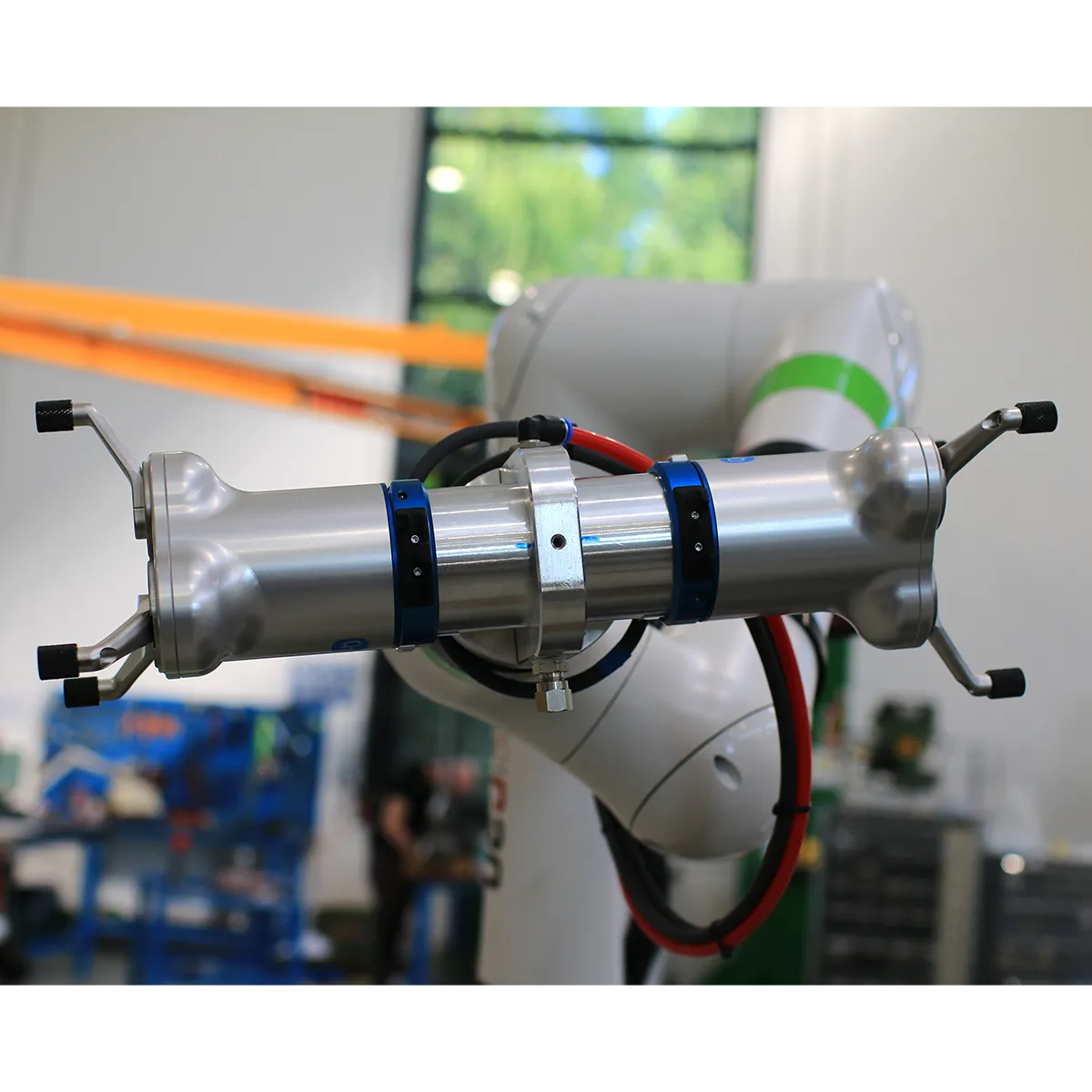

After the first meeting between the customer and our technical team, the customised RoboFeed C20 solution was identified as the most suitable to meet the customer’s needs and objectives.

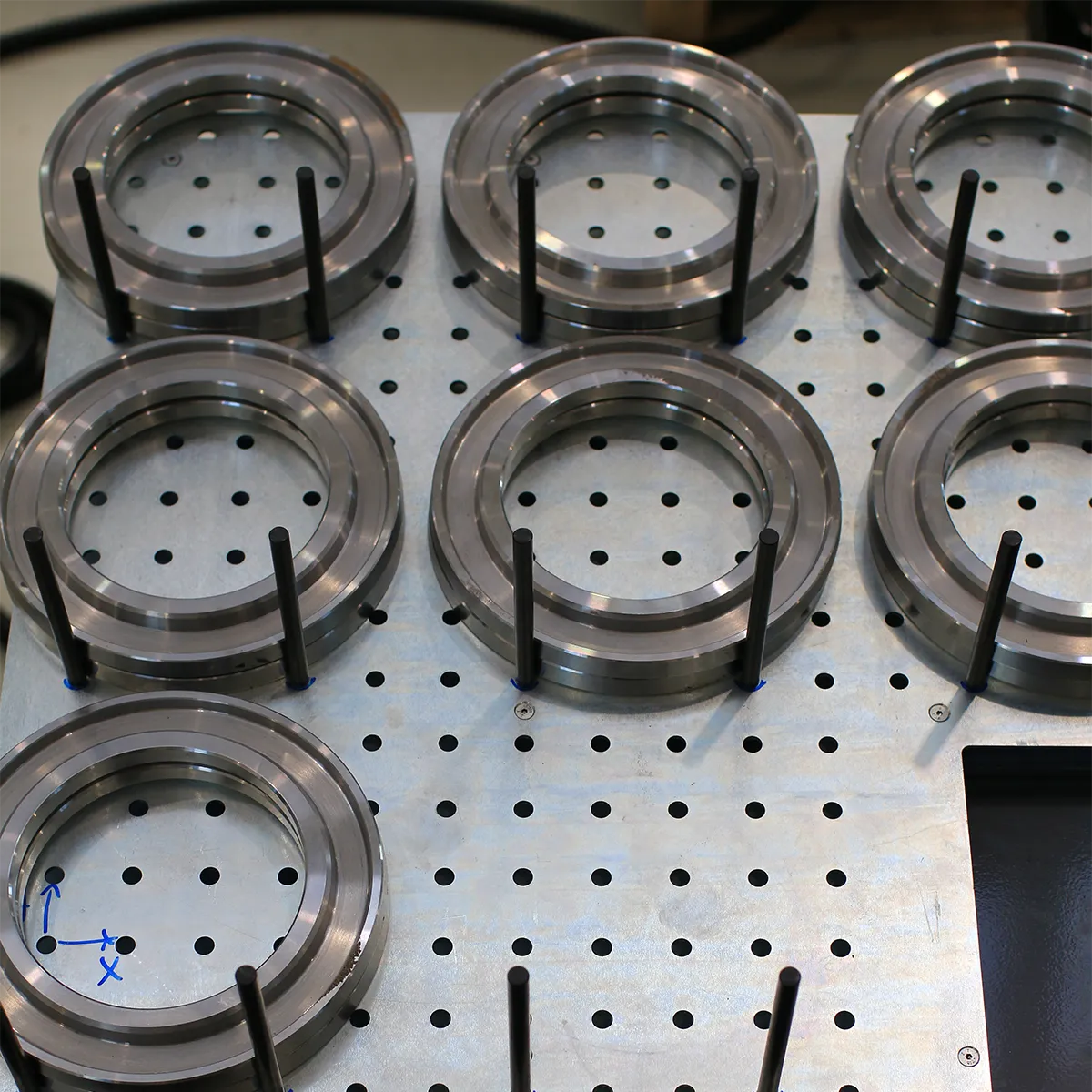

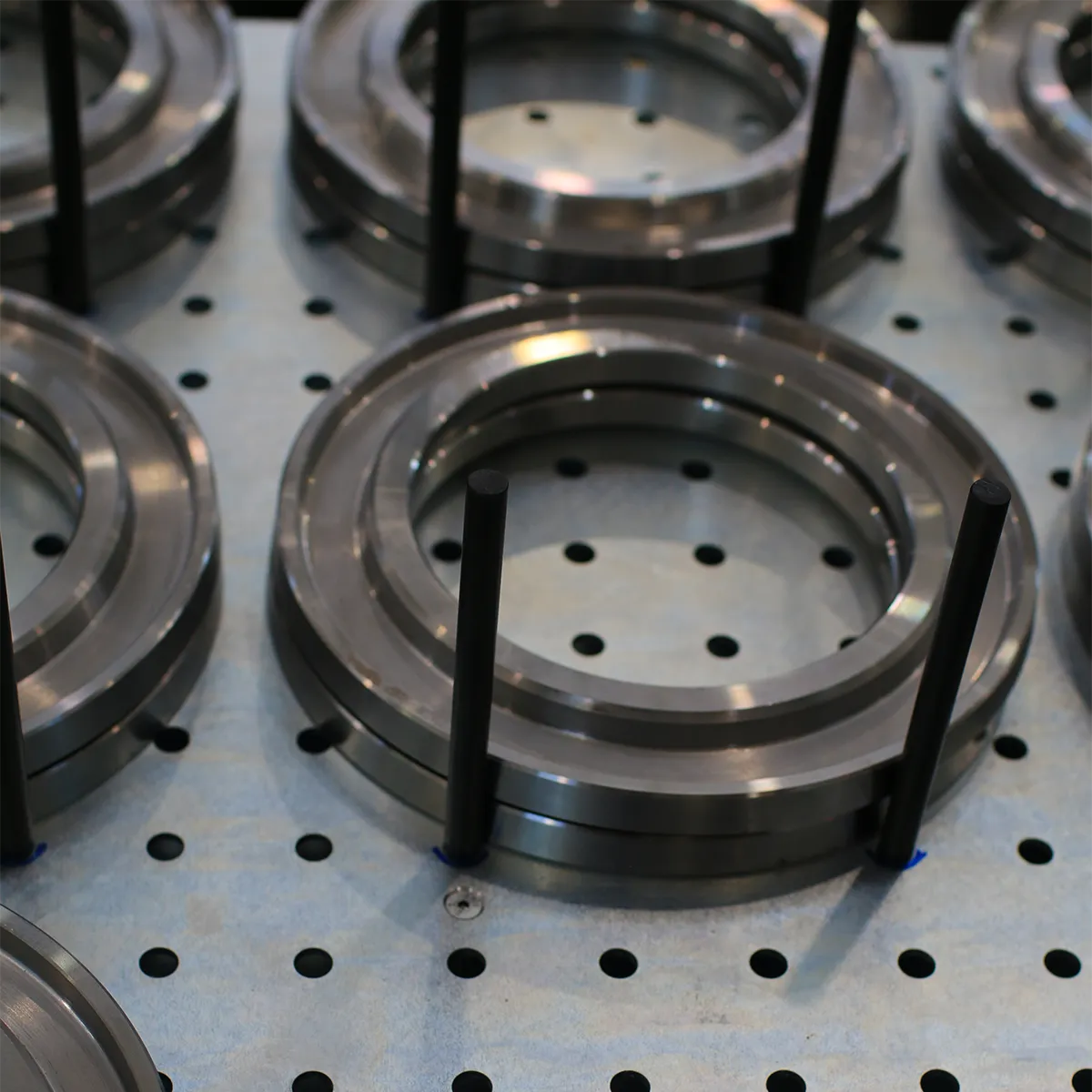

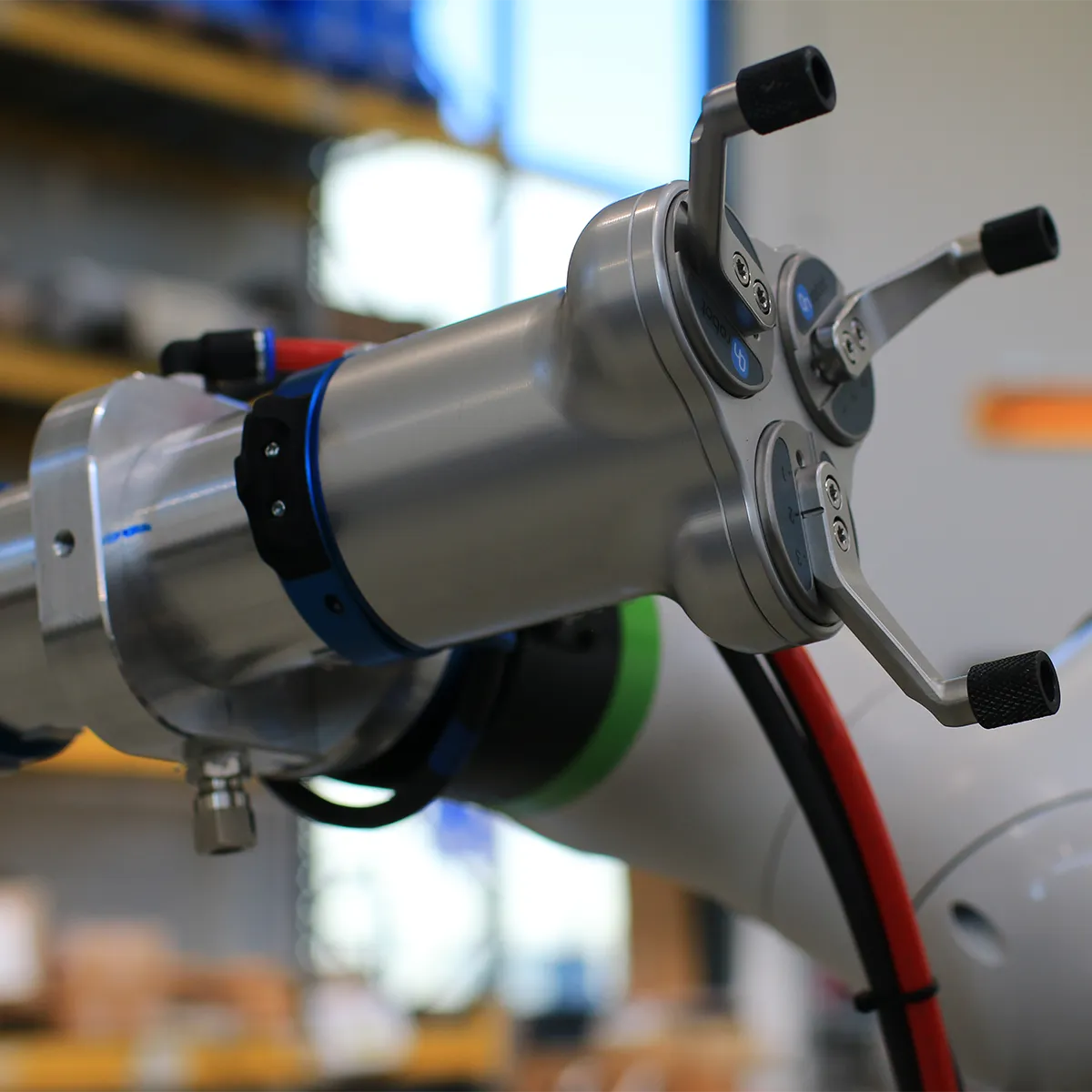

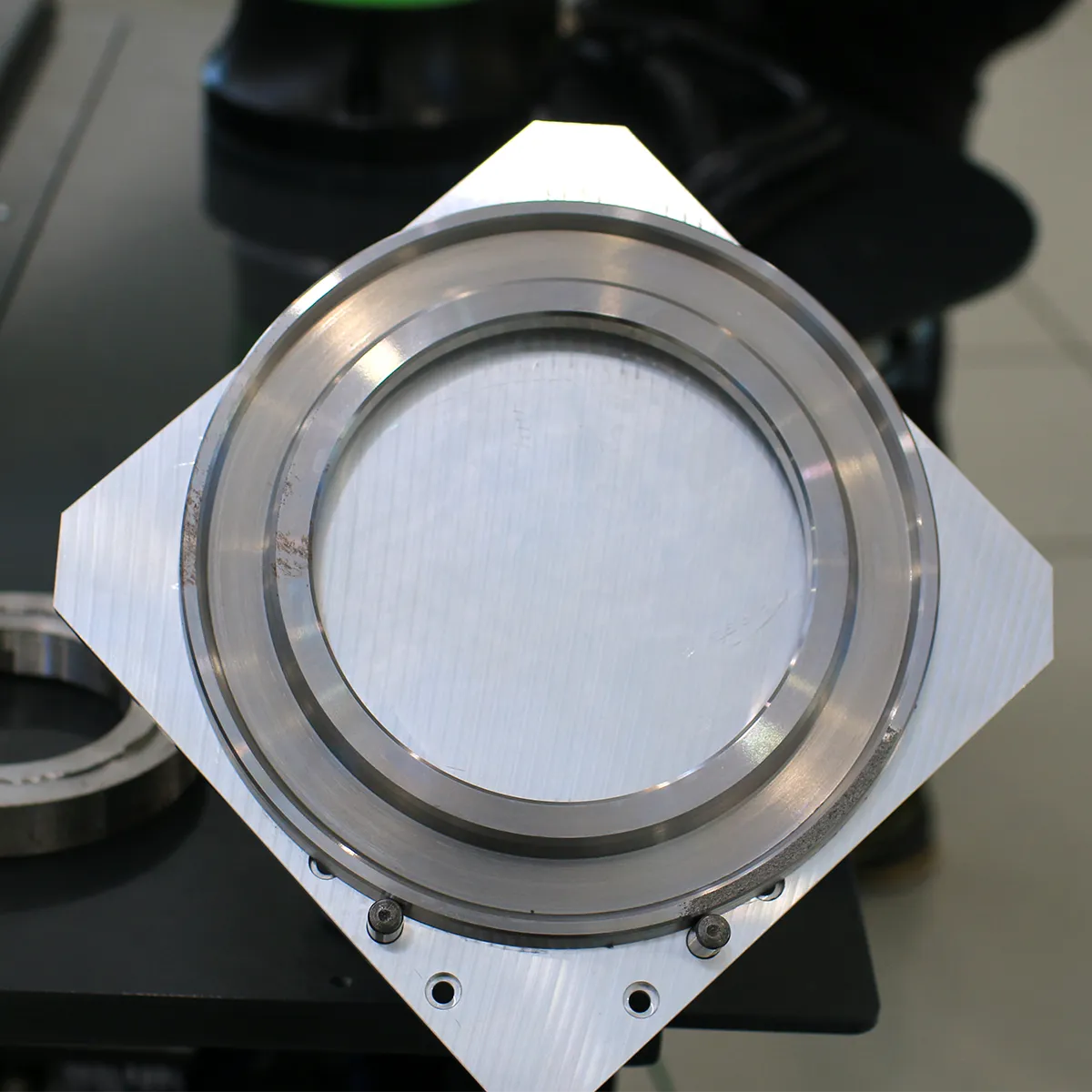

The chosen system included the FANUC CRX-10iA/L collaborative robot, with a load capacity of 10 kg and customisation of components such as jigs and wrist, but not only. Retrofit work was carried out on the machine tool of interest by our Assistec technical support team.