Spiral Ingranaggi srl, part of the TFM group and specialised in the production of gears for various industrial sectors, needed a compact automated solution to optimise the loading and unloading process of a GLEASON machine tool. The main objective was to reduce the cycle time from 3 minutes to 120 seconds, while maintaining high safety standards for their employees.

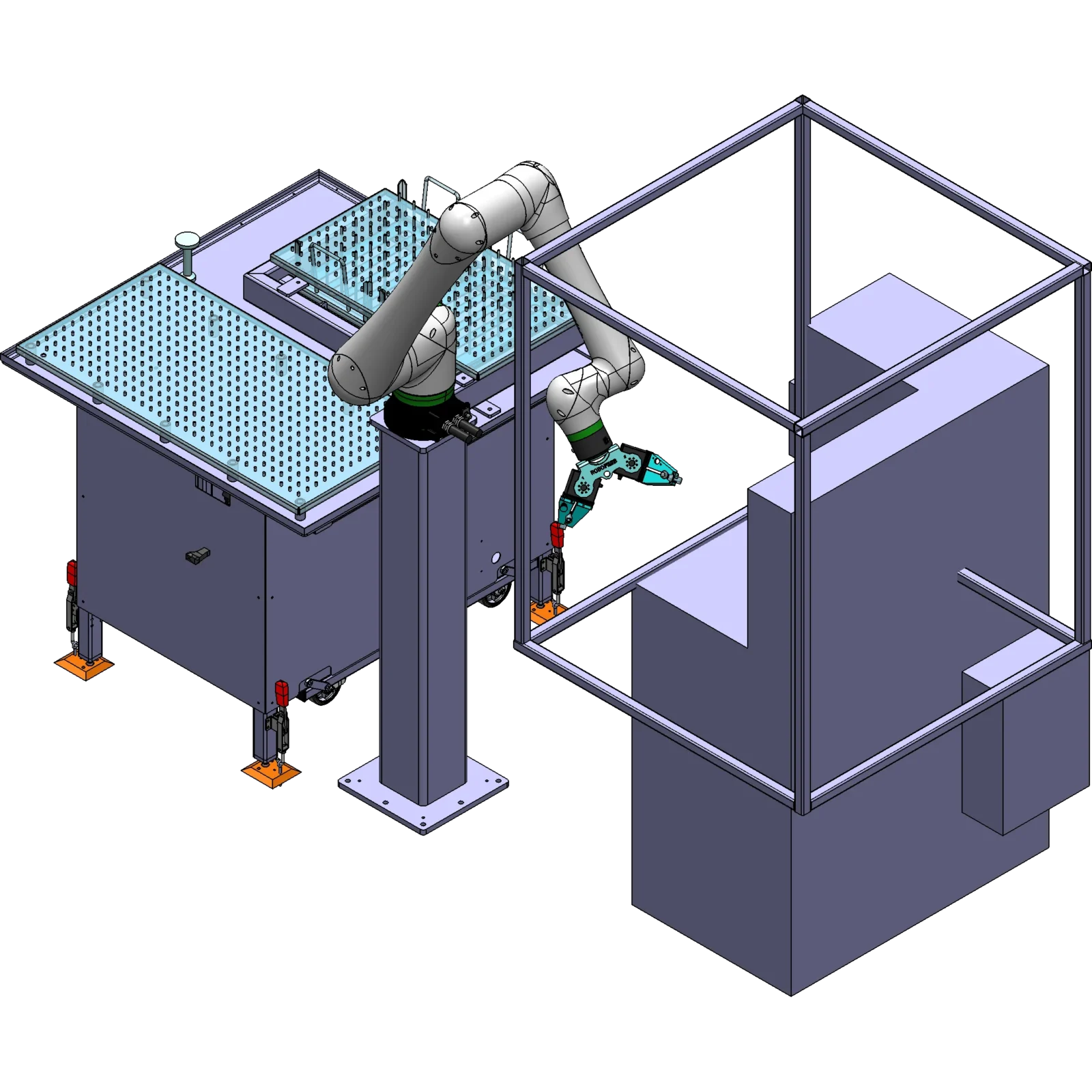

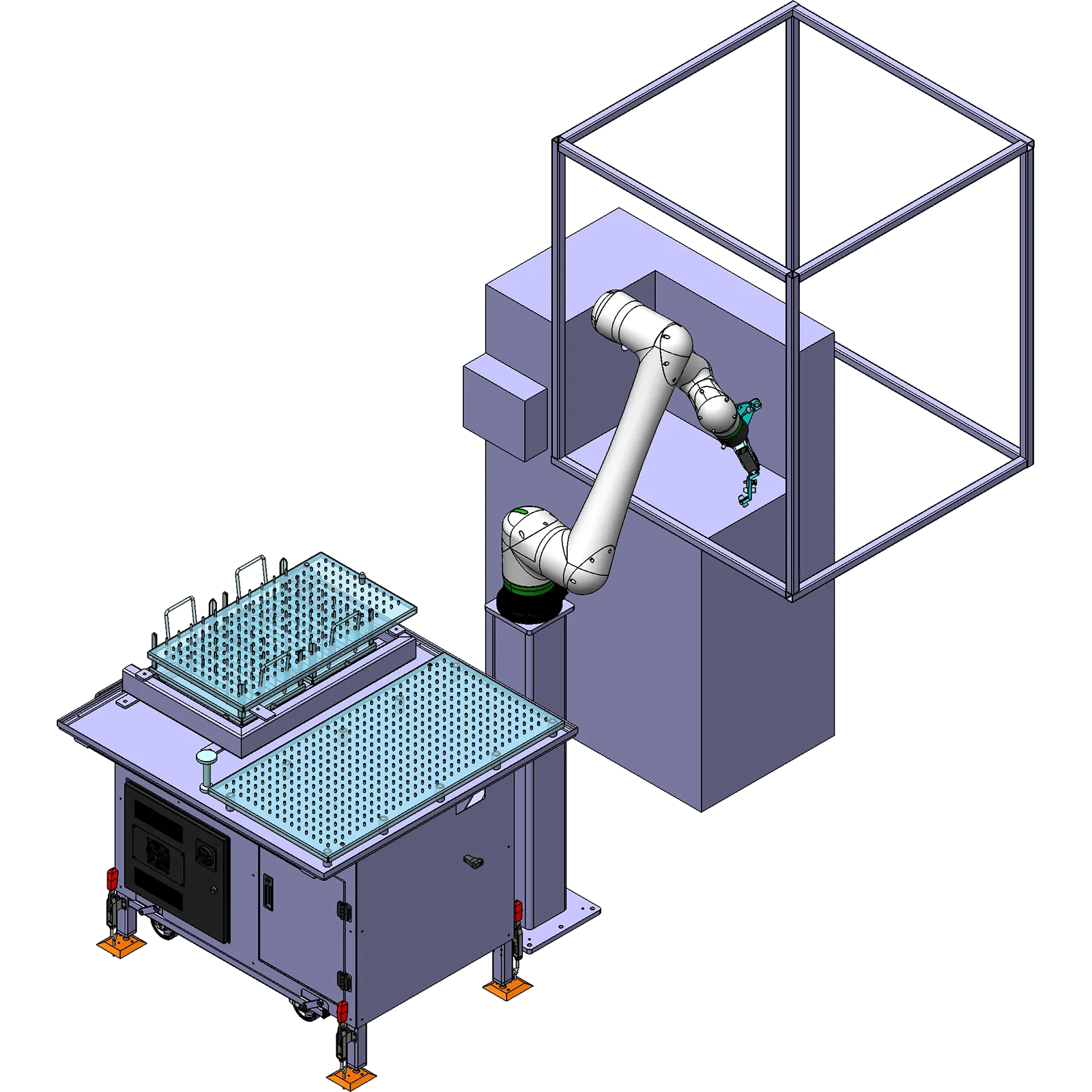

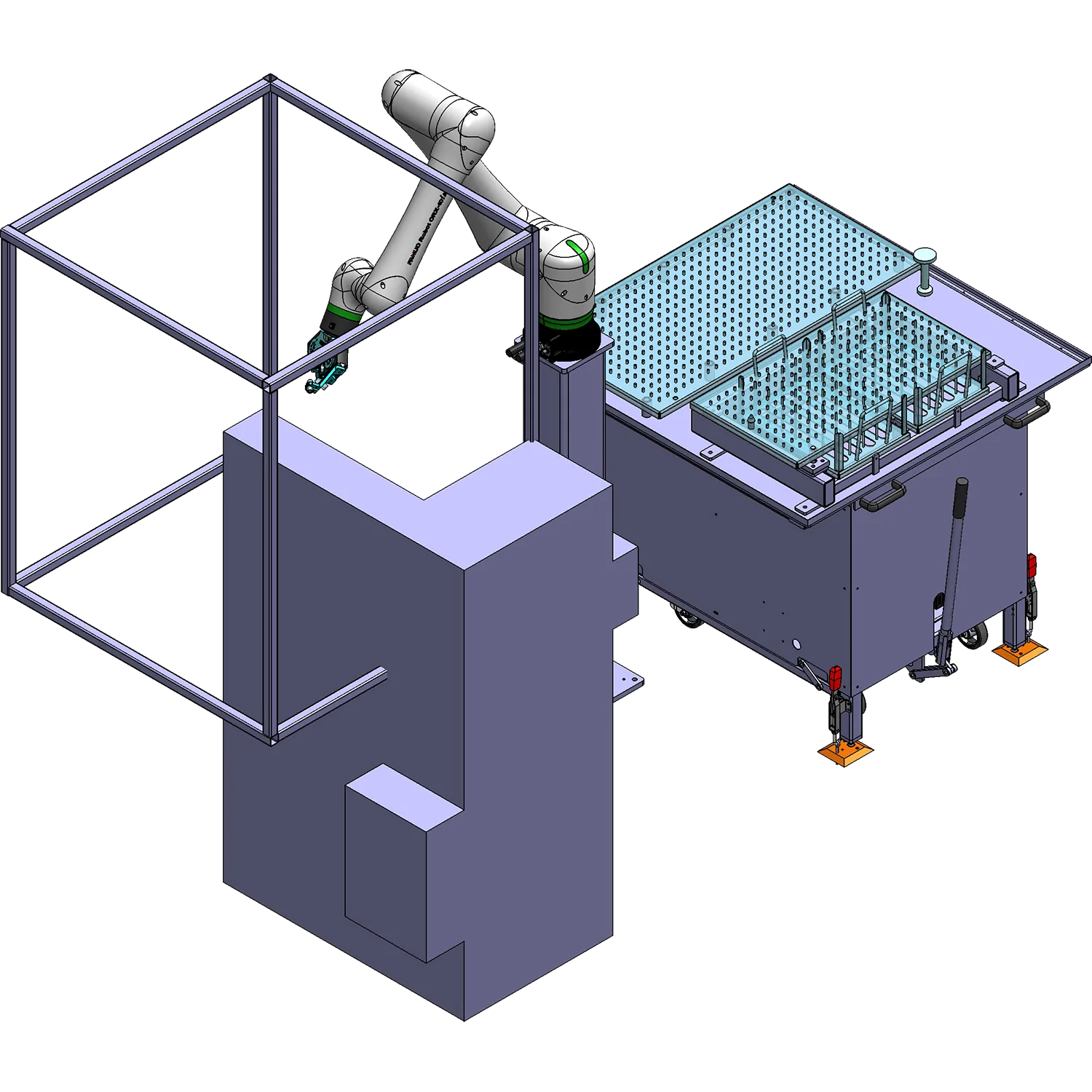

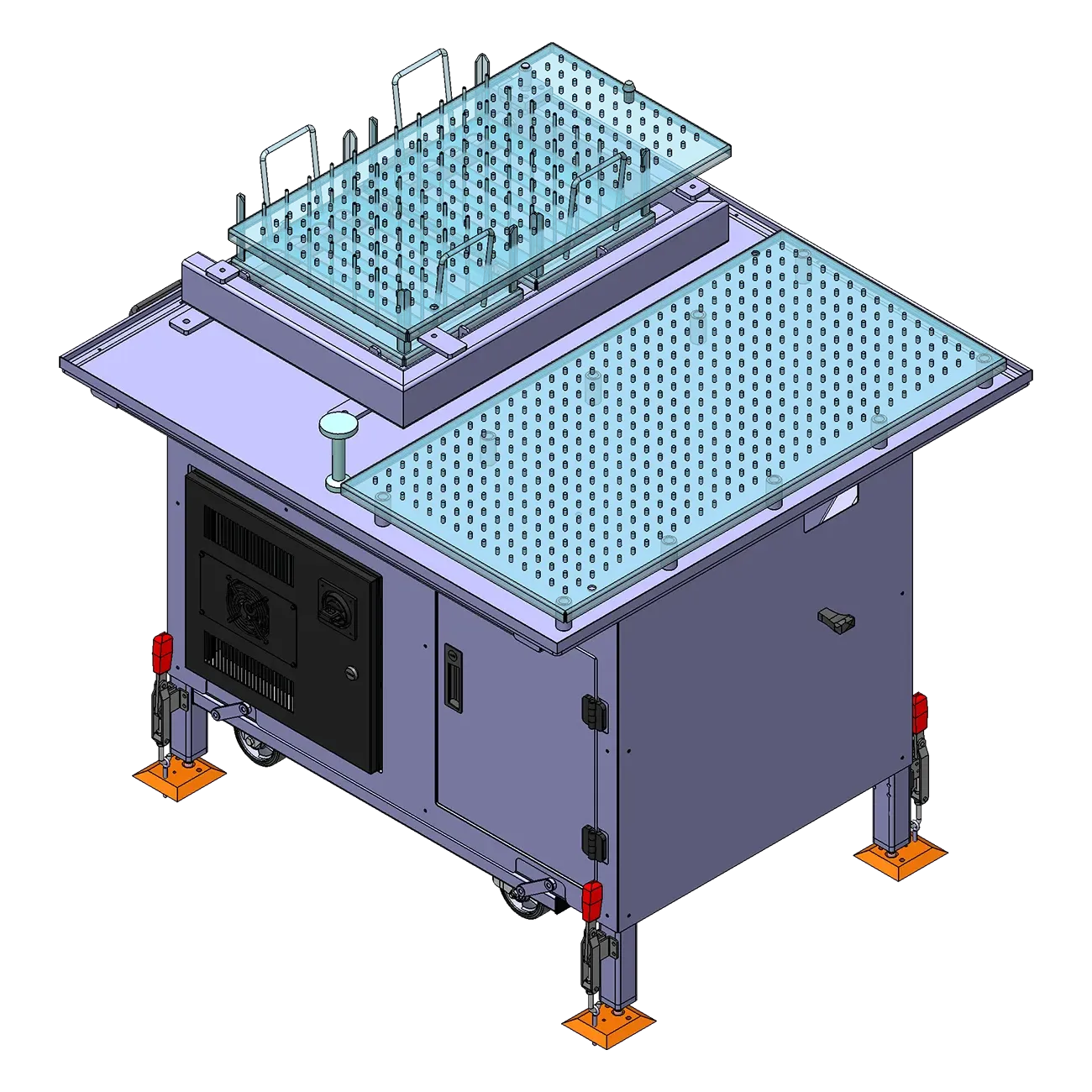

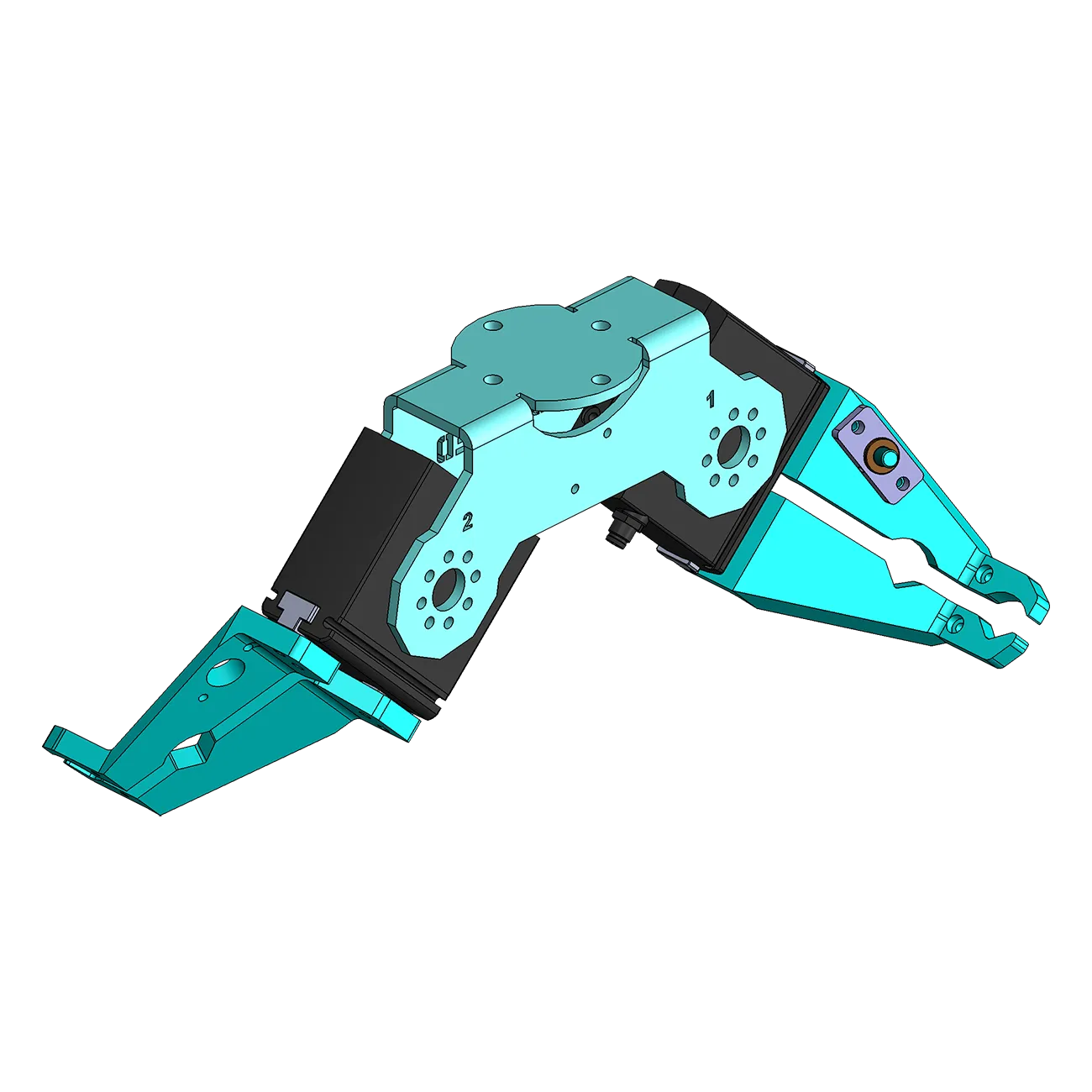

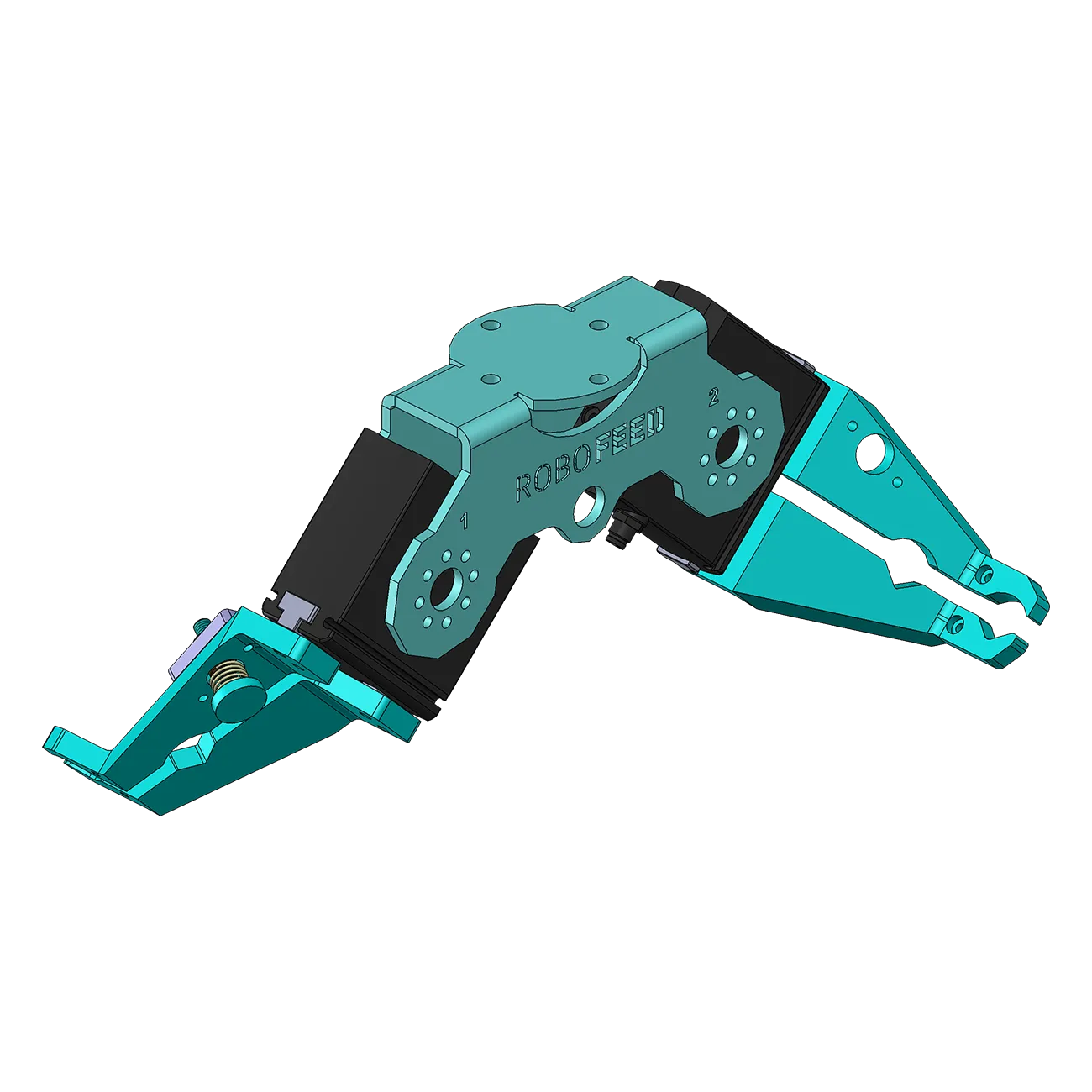

Solution: Robo Feed C20 Custom

After the first meeting between the customer and our technical team, the Robo Feed C20 Custom solution was identified as the most suitable to meet the requirements and objectives.

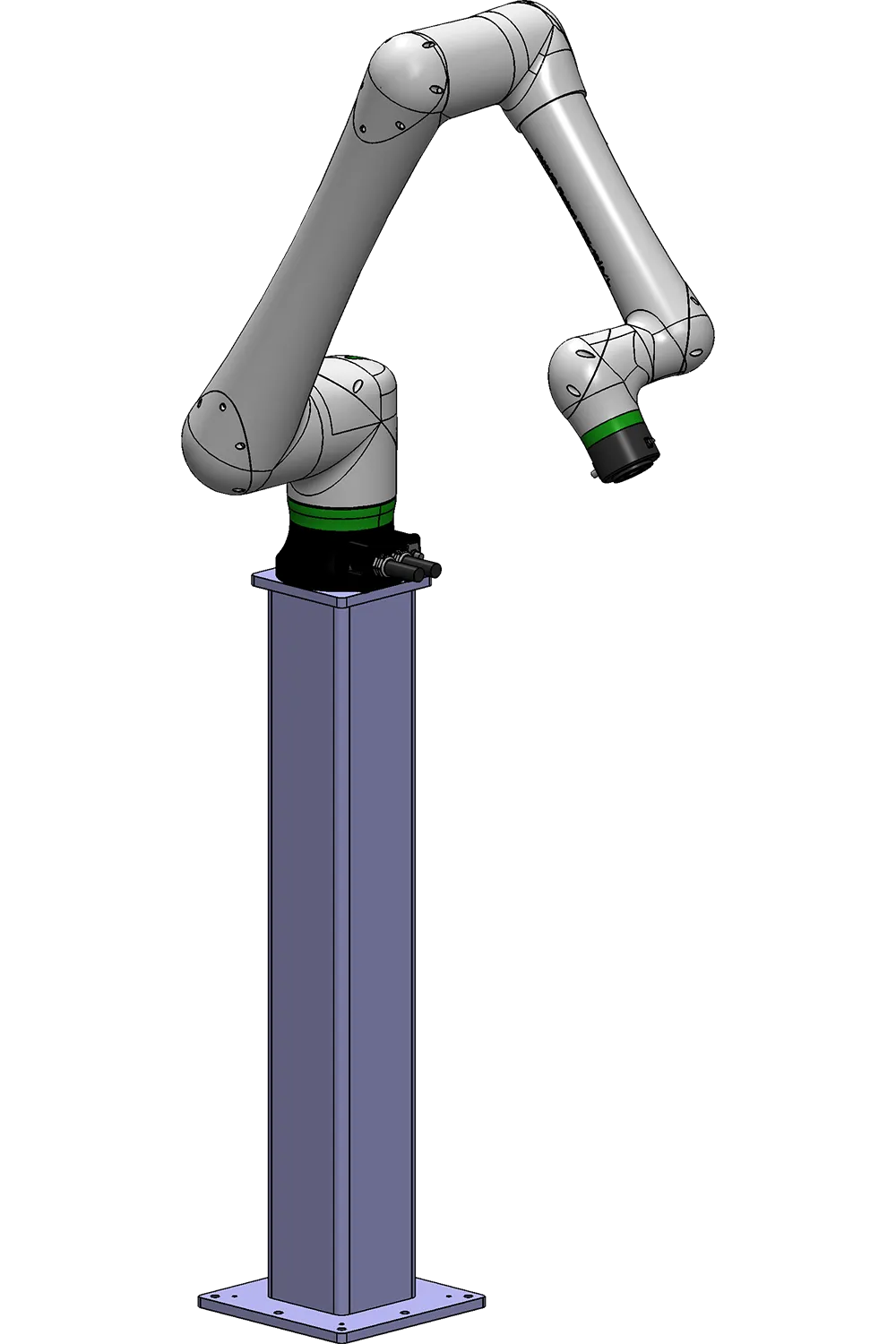

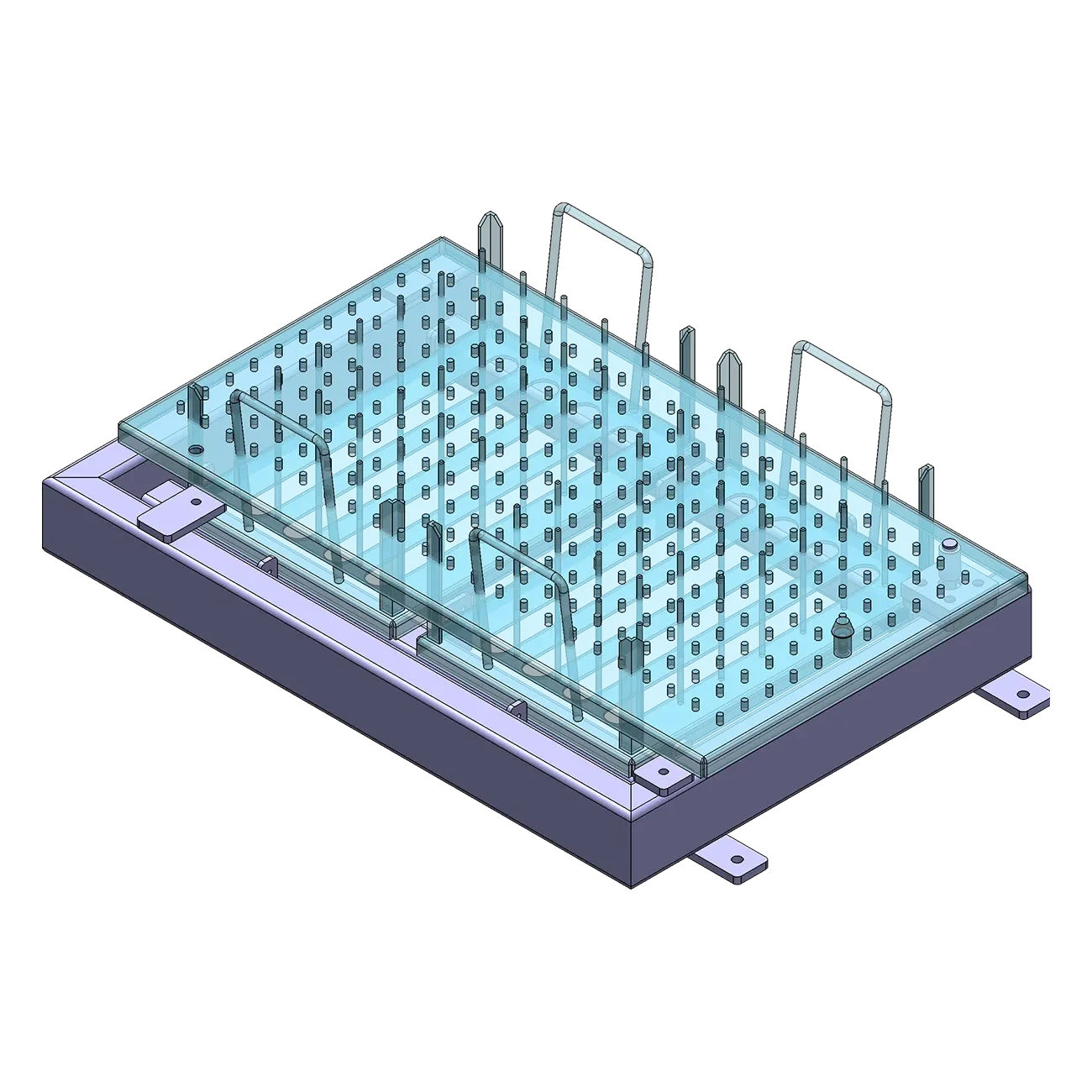

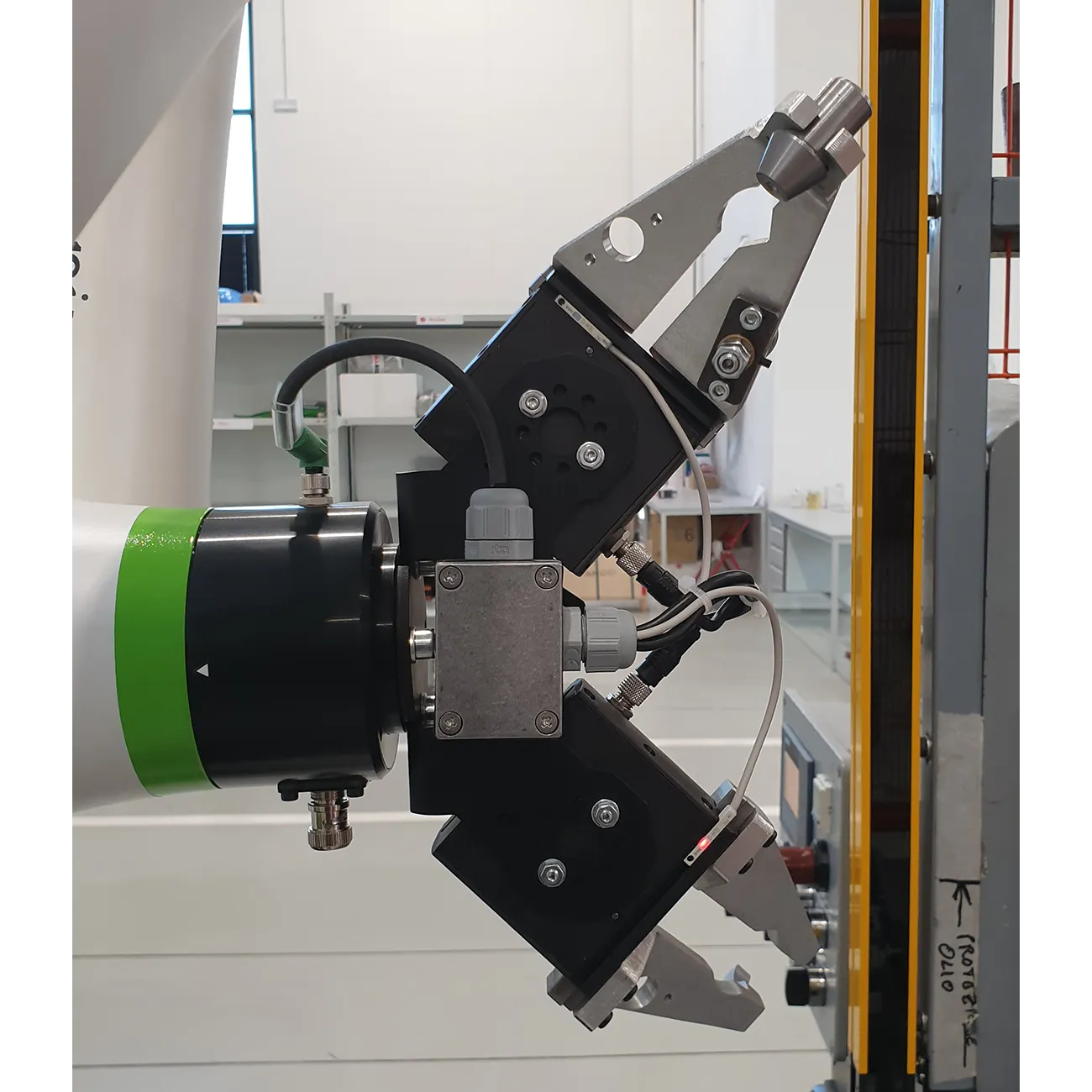

The system chosen included the FANUC CRX-10iA/L collaborative robot, with a load capacity of 10 kg. This customised version of the Robo Feed C20 was designed to integrate seamlessly into the machine shop, improving both production efficiency and operational safety.

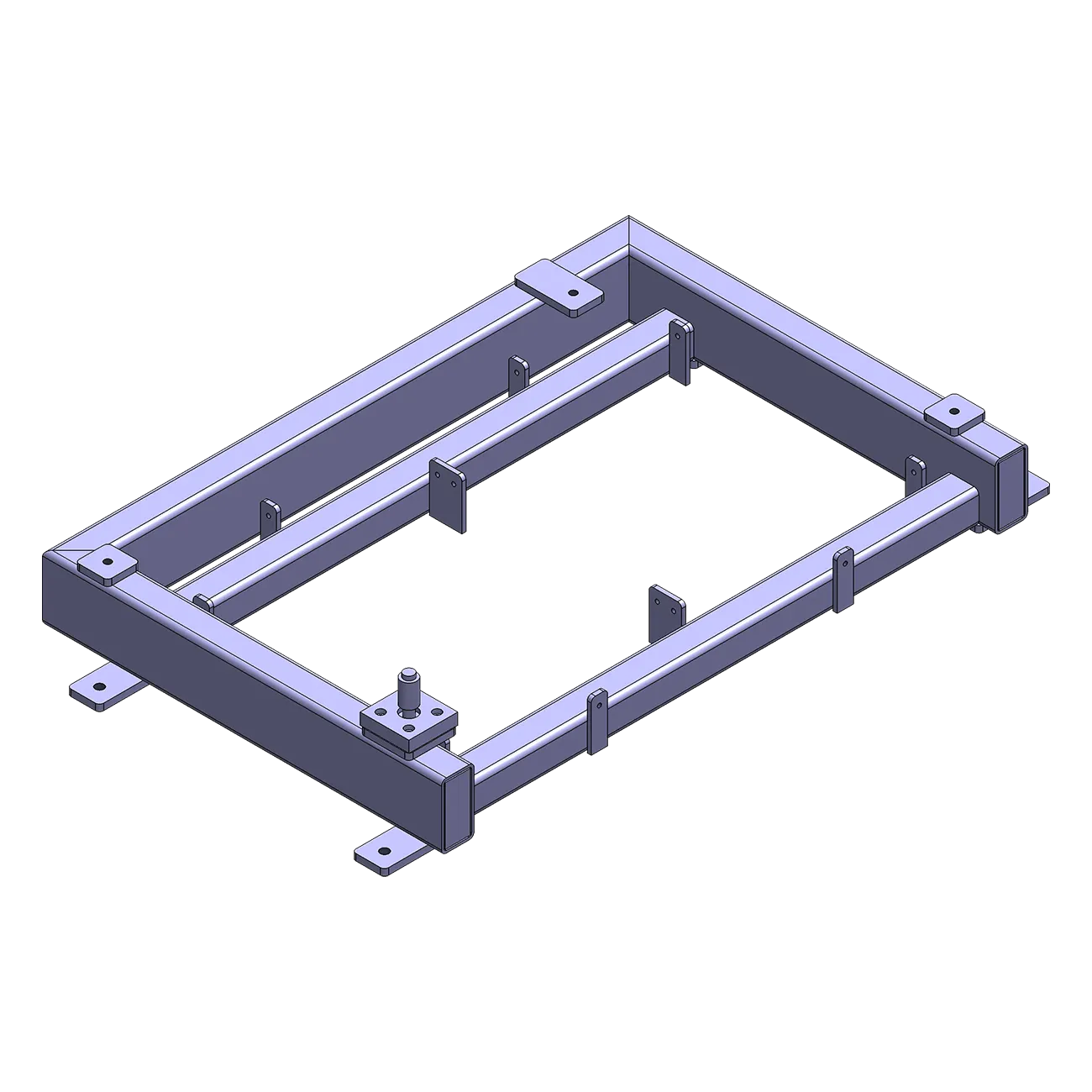

Compared to the standard C20 solution, this time the island itself has some differences.