roi

calculator

INVEST IN MACHINE TOOL AUTOMATION AND FIND OUT HOW MUCH YOU REALLY SAVE!

Assistec and ROI-Calculator by FANUC help you calculate an accurate estimate of the return on investment for automated servicing robots.

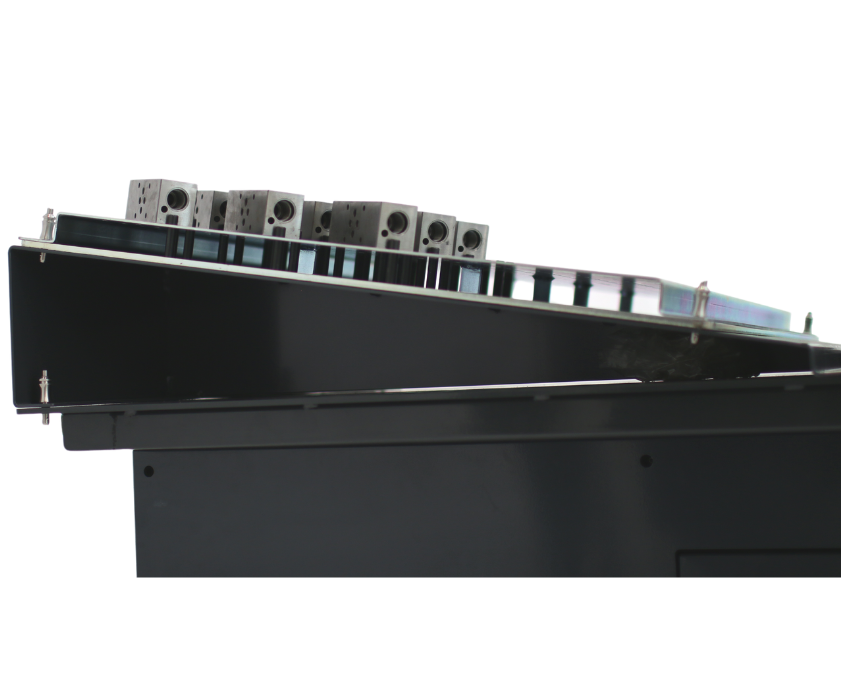

ROBO FEED C20 and C21 are the collaborative robotics solutions from Assistec, designed to meet the need to easily move the island from one machine tool to another thanks to an electric lifting system (optional). Ideal for the rapid production of even small batches.

Their compact dimensions and the absence of bulky structures save space on the shop floor and allow the machine to be used in manual mode, with one operator, as often as necessary.

The software developed by Assistec and the self-learning functions of the Fanuc Cobot reduce programming time and simplify the work of the toolmaker.

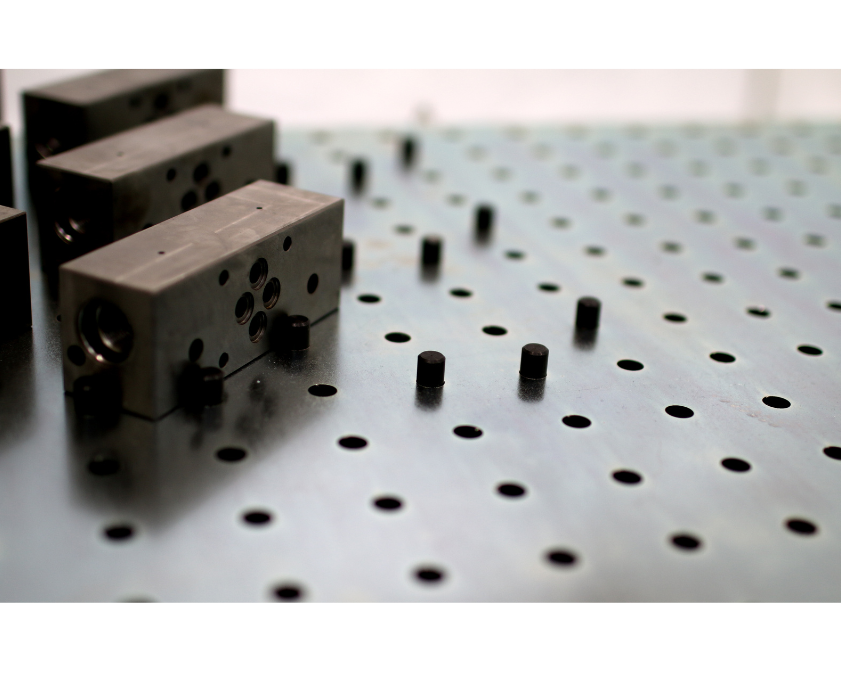

The modular C-series jig is characterised by its extraordinary loading capacity, which allows it to be easily adapted to different workpiece types.

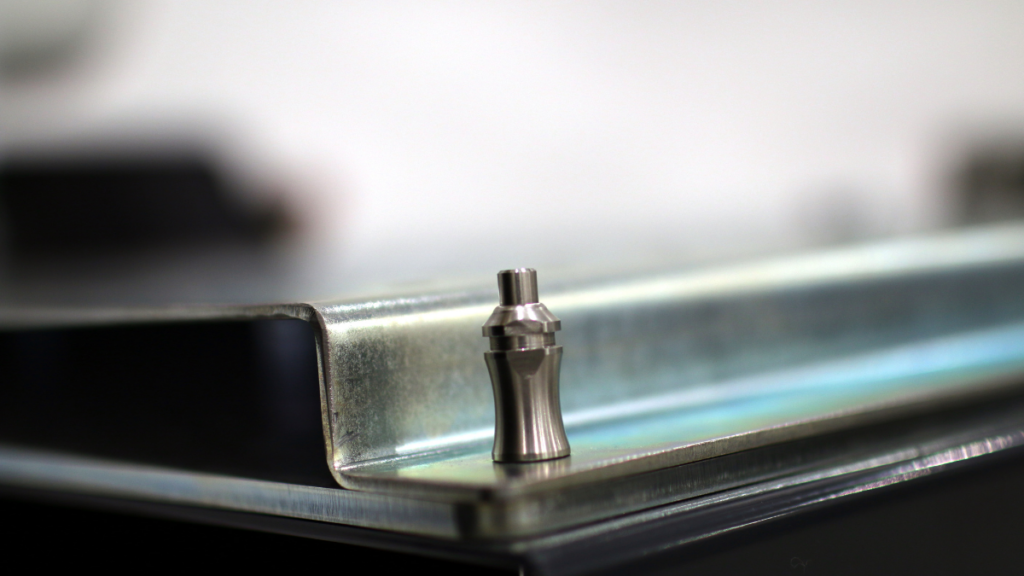

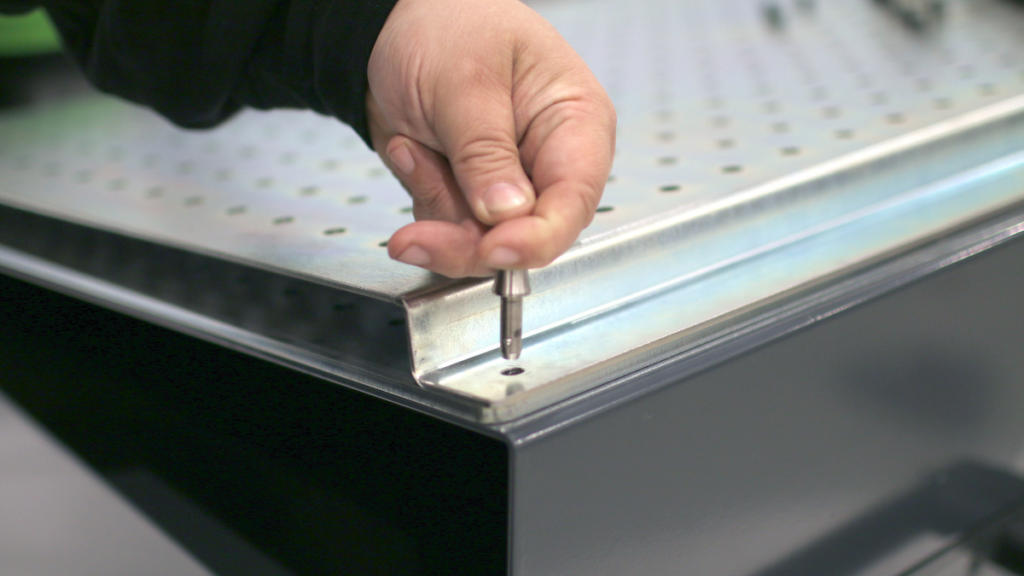

Thanks to the adjustable pegs, the housing can be configured quickly and easily, optimising the available space.

Ideal for small and medium-sized batches, it transforms the pallet into a truly flexible warehouse, capable of responding to the needs of any production process.

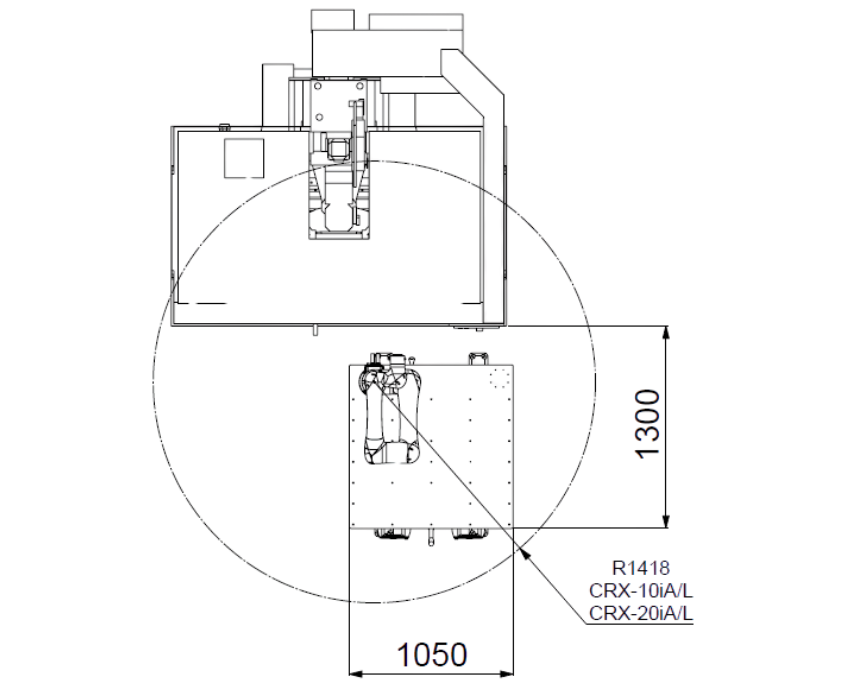

Space required for automation reduced to a minimum.

Thanks to the customised software developed by Assistec, programming the Fanuc Cobot becomes intuitive and immediate.

Manual handling of the robotic arm by the operator allows self-learning of the dimensions, reducing set-up times and optimising production.

In addition, the dedicated mobile app, integrated with the company system, allows real-time monitoring of machine data, ensuring constant control and efficient management of operations.

Fast movement from one machine tool to another.

The Electric Lift Option is the solution that simplifies and optimises movements between machine tools,

offering real advantages for your productivity.

The advantages of electric lifting:

C20 | C21 Cobot Fanuc CRX20iA/L | |

10 kg | Wrist capacity | 20 kg |

1418 mm | Robot reach | 1418 mm |

870 mm | Height | 870 mm |

1.280 mm | Width | 1.280 mm |

1.050 mm | Depth | 1.050 mm |

0,90 mq | Usable loading surface | 0,90 mq |

250 kg | Weight of unit | 250 kg |

| 1,6 KVA | Installed power | 1,6 KVA |

Assistec and ROI-Calculator by FANUC help you calculate an accurate estimate of the return on investment for automated servicing robots.