The A3 models are designed with a tower warehouse with drawers integrated in the structure, with a double bay for loading and unloading parts without machine downtime.

Immediate monitoring of production progress thanks to machine-side LED indicators.

The quick installation and configuration of the island, as well as its compact dimensions, allow it to be perfectly integrated into the workshop.

Mechanics

Medical

Food

Earthmoving

Aerospace

Automotive

Machinery

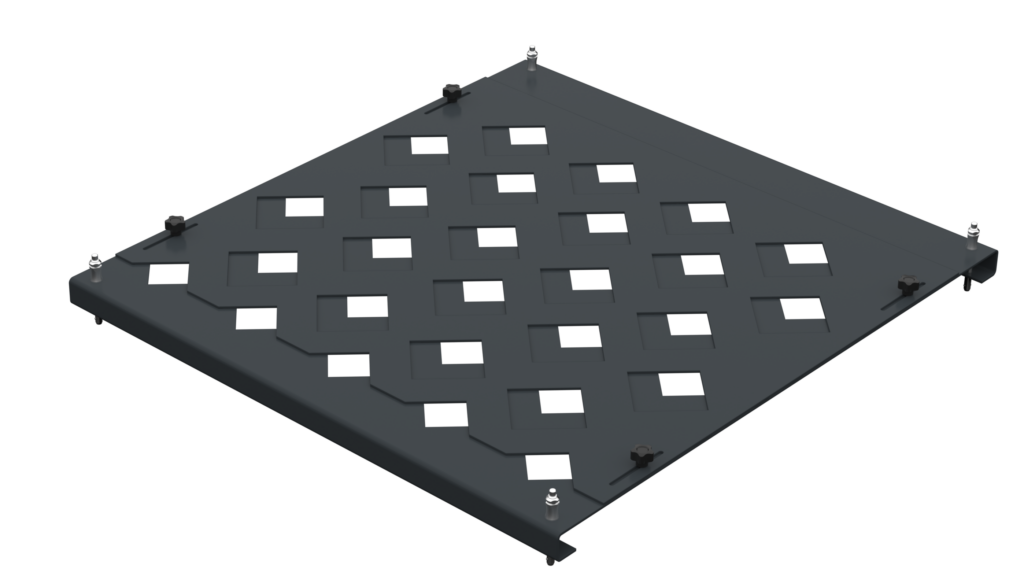

for quick retooling of drawers.

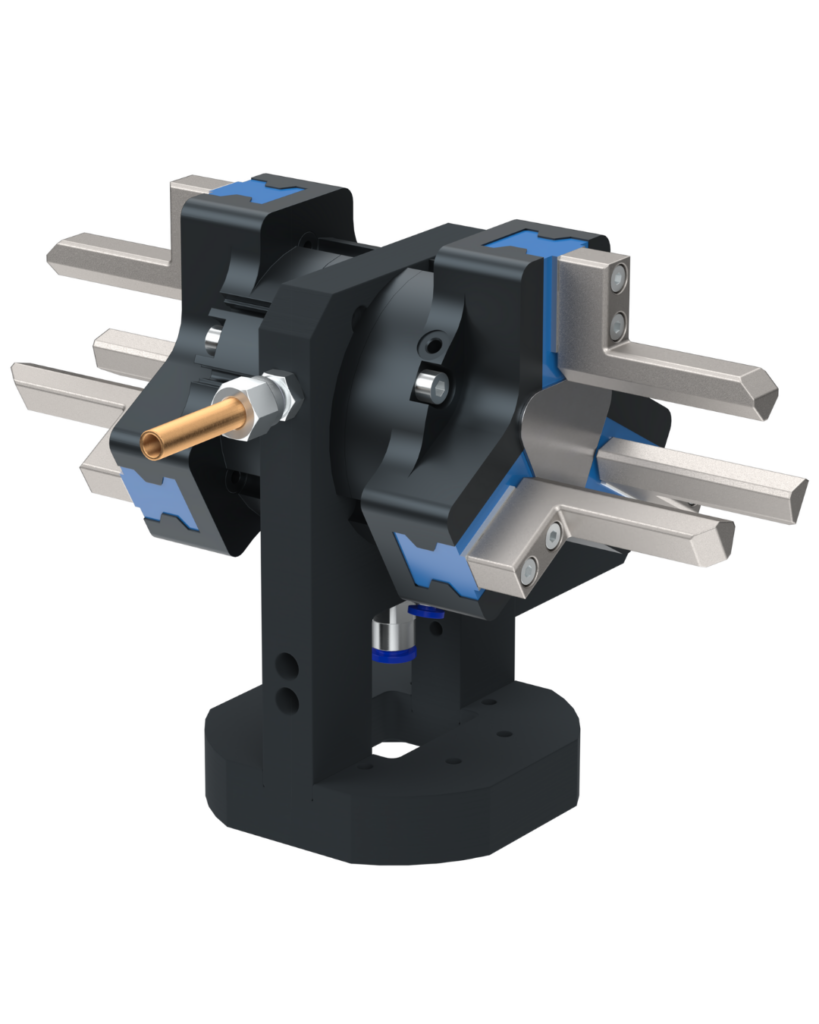

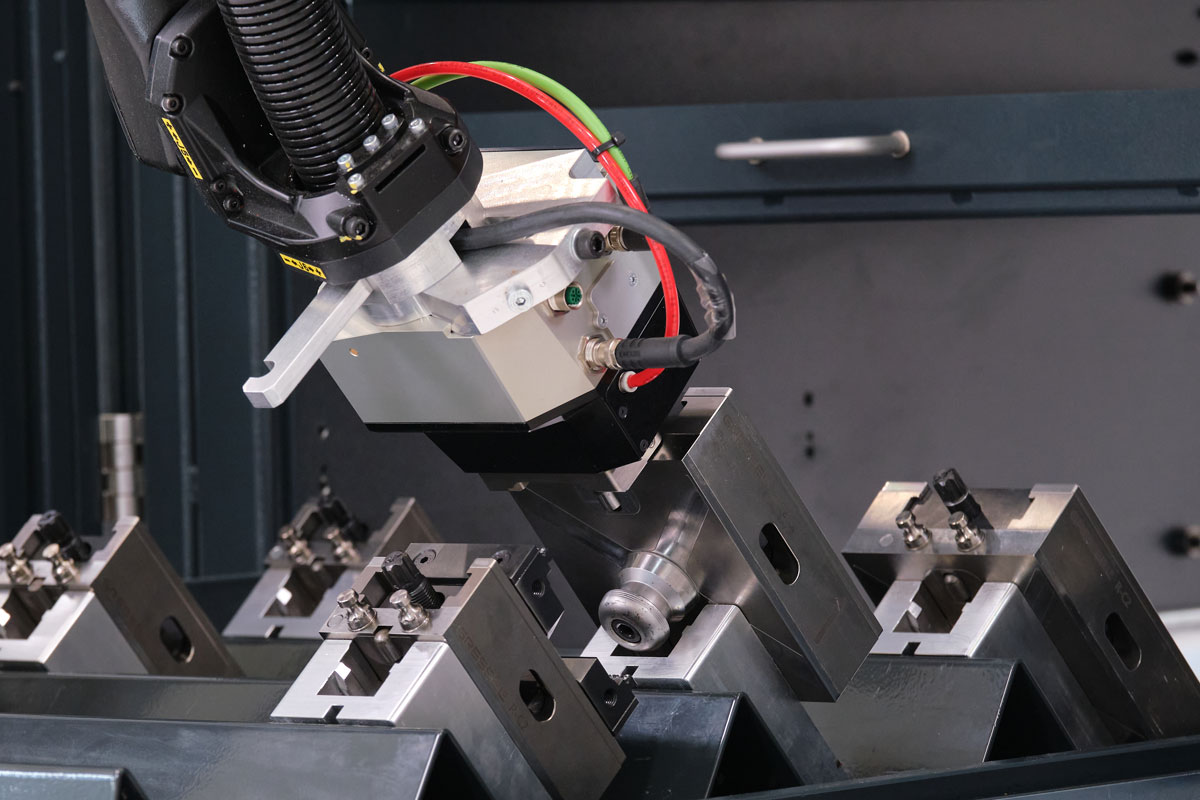

The Assistec modular jig is designed for maximum versatility in handling different types of parts.

Thanks to specific adjustments, the operator can quickly adapt it to production requirements, reducing downtime and increasing efficiency.

Re-tooling is intuitive and fast thanks to the dedicated tackers, which simplify positioning and clamping operations, improving the accuracy and repeatability of the process.

With the possibility of personalising the brand names

(*indicative data to be verified according to the model selected)

excluding options and clamps

excluding options and clamps

excluding options and clamps

Centring station

Tilting station

Deburring station

Deionisation station

Redevelopment station

2D vision

Innovative gripping and clamping system

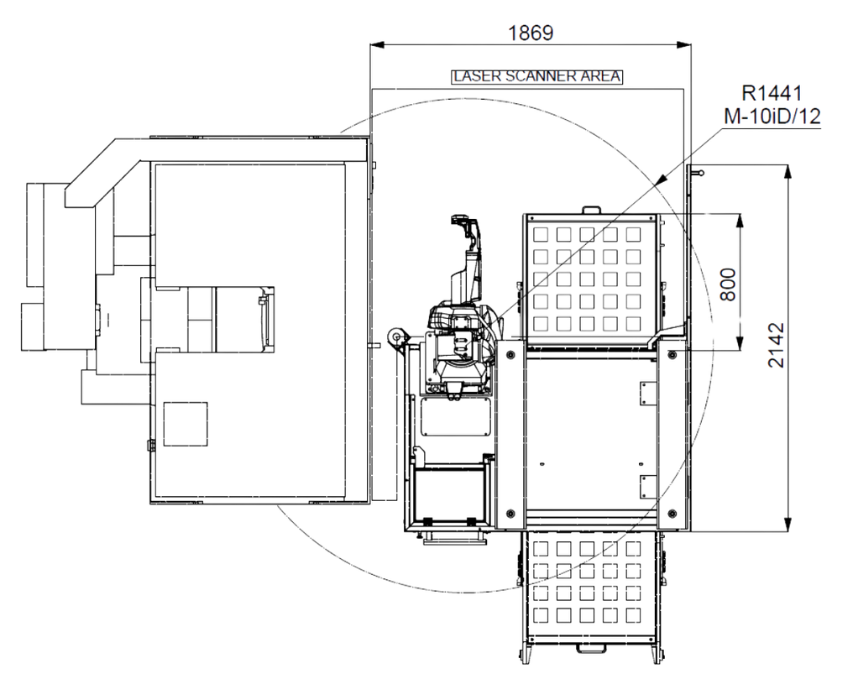

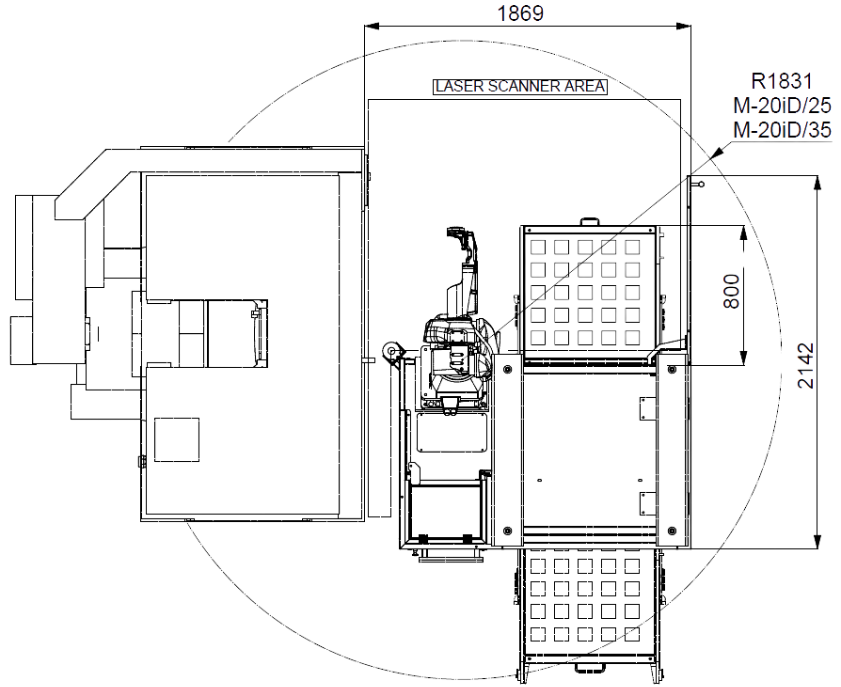

AVAILABLE IN CONFIGURATION WITH FANUC M20 ID/25 ROBOT

25 KG LOAD CAPACITY AT WRIST AND REACH OF 1831 MM.

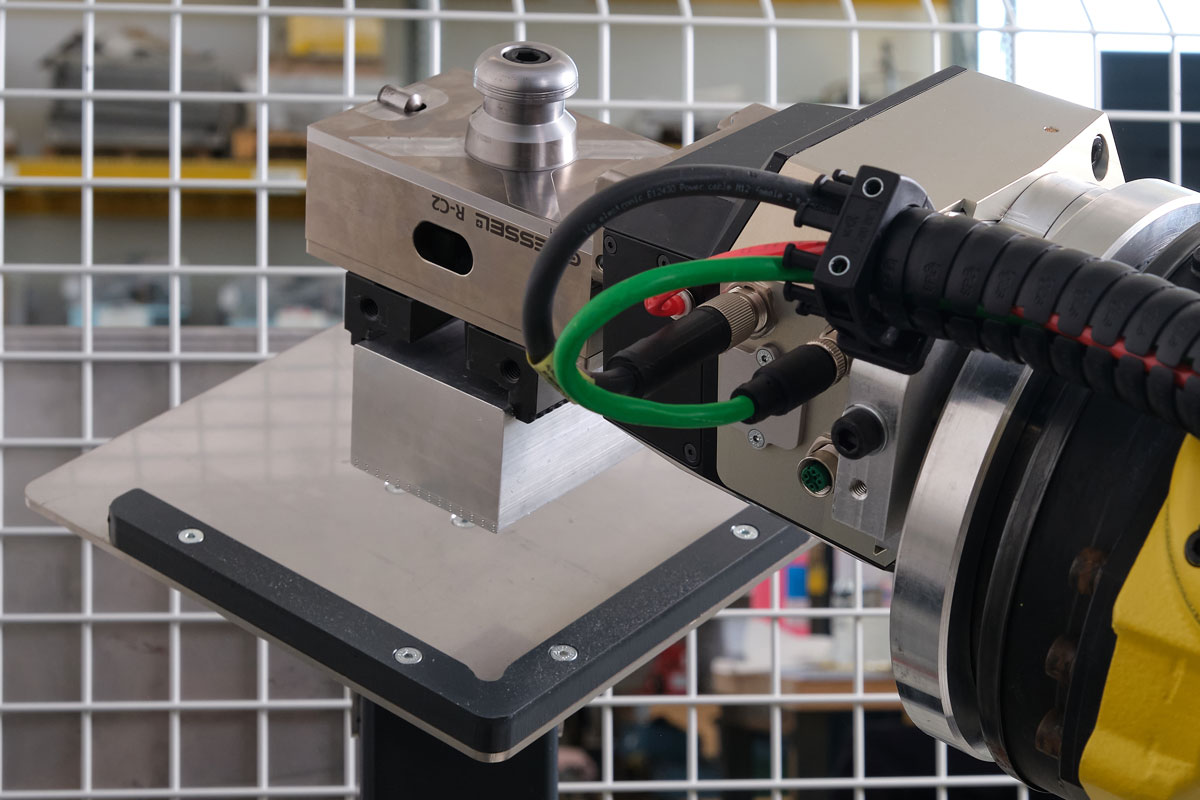

The result of a deep synergy between Assistec and Gruppo SCHUNK GmbH & Co. KG, this system guarantees the machining of all blank faces in complete autonomy.

The Robofeed A31 with Gressel R-C2 option is one of our plug & play solutions with anthropomorphic robot for machine tool servicing.

Equipped with a drawer magazine with double-bay drawers integrated into the structure, the R-C2 option allows the robot to directly handle self-centring vices for workpiece gripping and loading directly on the machine using a zero-point module.

Its compact size and the presence of a laser scanner that eliminates the need for physical safety barriers, allow for installation even in limited spaces. This guarantees maximum access to the machine tool for retooling or manual operations.

The robotic cell is characterised by a tower magazine with 7 drawers extractable both on the robot side and operator side dedicated to the workpieces, and a drawer dedicated to clamp storage with 12 stations.

The loading of unmachined pieces and the unloading of machined pieces from the drawers are carried out without interrupting the machining cycle and the operator can access and extract them in complete safety.

Each drawer has a size of 755 x 805 mm, an available height of 145 mm and maximum capacity of 150 Kg: these measurements make the Robofeed magazine one of the most spacious compact solutions on the market.

Robofeed A31 is also suitable for small-medium production lots, thanks to the quick retooling of the drawers and the simplified software used to manage the pick-up points in the magazine, combined with the R-C2 system.

Light signals also make it easy for the operator to identify the status of the production cycles, and machine maintenance is facilitated by the slide opening of the side door.

As standard, Robofeed A31 with the Gressel R-C2 option is equipped with a drawer for storing a sample piece for quality control, either at the operator’s request or at a programmed frequency.