In modern manufacturing, automation is no longer an optional choice, but a strategic requirement to remain competitive. Thanks to our experience, we know that every production plant has unique characteristics, and standard solutions are often not enough. This is where customised robot cells come in: automation systems tailored to meet the specific production, logistical and quality requirements of each customer.

With the ROBO FEED Custom service, our company builds on more than 20 years of success in technical support and system integration to create flexible, high-performance solutions that are integrated with existing machine tools.

Need to know more? Here you will find out how they work, what benefits they offer, where they apply and why they are an essential tool for Industry 4.0 (and 5.0) today.

Indice dei contenuti

ToggleWhat are customised robot cells?

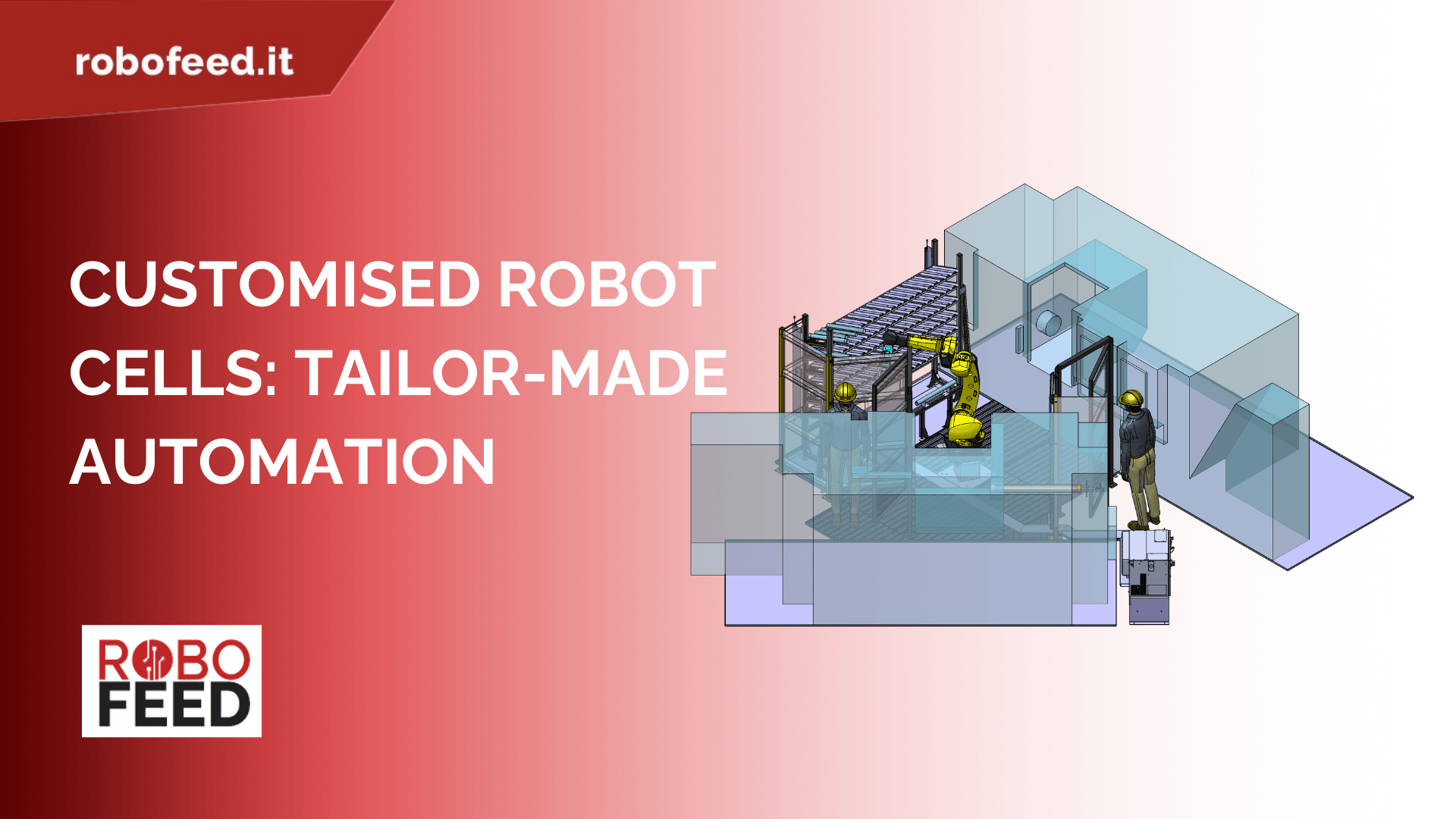

A customised robot cell is an automated system designed ad hoc to manage specific operations on CNC machine tools: part loading and unloading, tooling change, robot cells with quality control, intelligent handling. Customisation concerns:

- Plant layout

- Robot type and configuration

- Workpiece gripping and tooling system

- Interface with the CNC

- Level of autonomy required

- Vision systems (2D/3D)

- Flexibility on multiple references and variable batches

ROBO FEED’s ability to design these islands starts with a key element: the analysis of the customer’s production process, in order to correctly dimension the operational autonomy, minimise human intervention and guarantee continuity even during unmanned night shifts.

The concrete advantages of customised automation

Choosing a customised solution allows you to overcome the limitations of a standardised cell.

The advantages? They are truly numerous.

1. Increased productivity and machine efficiency

A well-designed island allows maximum utilisation of spindle hours, reducing downtime between machining operations. The robot can feed one or more machines in sequence, ensuring continuous production and intelligent priority management.

2. Integrated quality control

The integration of 2D and 3D vision systems makes it possible to perform automatic dimensional checks and detect aesthetic or machining defects already in the unloading phase. In addition, the measuring stations can interface with the CNC to automatically correct tool parameters, making the cycle totally autonomous.

3. Reduced labour costs and lower inventories

A customised robot cell reduces the number of operators involved, decreases errors and cuts downtime costs. Just-in-time production reduces inventory and increases gross operating margin.

4. Flexibility and future adaptability

ROBO FEED solutions are designed to accompany the evolution of production: they adapt to range changes, new batches or different part types, without having to redesign the entire plant.

5. Tax advantages through Industry 4.0 and 5.0

They are fully covered by the incentives provided for the digital and automated transition of production processes. The investment quickly pays for itself, not only in terms of efficiency, but also in tax credits under the Industry 4.0 and Industry 5.0 programmes.

Customised robot cells: fields of application

Although the company is focusing on standardised solutions for production efficiency, more than 85% of requests are for customised projects. This is because custom islands find application in numerous industries, including:

- Precision Mechanics

- Automotive and component parts

- Oil & Gas

- Moulds and equipment

- Aerospace

- Medical

- Packaging and fine handling

Each production context has unique requirements in terms of loading/unloading, traceability, quality control, speed and safety. Customised robot cells are able to adapt to all these variables.

Customised robot cells: ROBO FEED Custom

ROBO FEED Custom integrates several advanced subsystems, including:

- Robotic islands with 2D machine vision: defect control, scratches, visual quality

- CNC cells with 3D vision system: unmanned picking of parts from bulk bins

- Conventional measuring benches or integrated automatic probes

- Advanced Robot-CNC interface for precise communication

- Cycle simulation and optimisation software

Thanks to their in-depth knowledge of machine tool operation, Assistec engineers are able to implement smooth and stable communication between robot and CNC, even in environments with complex architectures or machines of different generations.

Design of customised robot cells

The approach to designing a customised island by ROBO FEED engineers follows clearly defined steps:

- Analysis of the production process and real requirements

It always starts with a technical inspection and a direct discussion with the production manager. - Feasibility study and automation proposal

A preliminary layout and cycle simulation is carried out to evaluate advantages and criticalities. - Mechanical, electrical and software design

The ROBO FEED team takes care of every aspect in house, ensuring full control over the result. - Installation and commissioning at the customer’s site

Commissioning is quick and assisted by specialised technicians. - Staff training and after-sales support

A distinctive feature is continuous support: updates, modifications, remote or on-site assistance.

Why invest in a customised robot cell today?

In an increasingly dynamic market with small orders, high variability, quality control requirements and pressure on margins, customisation of automation is a decisive competitive advantage.

- Reduce dependence on labour

- Increase productivity

- Improve final product quality

- Respond faster to market demands

- Get a measurable return on investment

Conclusion

ROBO FEED customised robot cells are much more than an extension of the production line: they represent a complete transformation of the way production is managed, from a flexible, autonomous and digital perspective.

Each solution is born from a thorough technical analysis, developed with integrated in-house design, and completed with direct, reliable and continuous support. To find out if a ROBO FEED Custom solution is suitable for your production plant, contact us for a free consultation. Your customised automation may be closer than you think.

FAQ

A standard robot cell has a fixed, ready-to-use configuration, suitable for repetitive and established processes. A customised one, on the other hand, is tailored to the customer’s specific needs: type of part, production layout, required autonomy, vision systems and operational flexibility.

The time varies depending on the complexity of the plant and the requirements. On average, the complete cycle – from initial analysis to commissioning – can take between 8 and 20 weeks.

Yes. ROBO FEED Custom specialises precisely in the integration with machine tools already in the company’s fleet, even of different brands and generations, thanks to a consolidated know-how in robot-CNC interfacing.