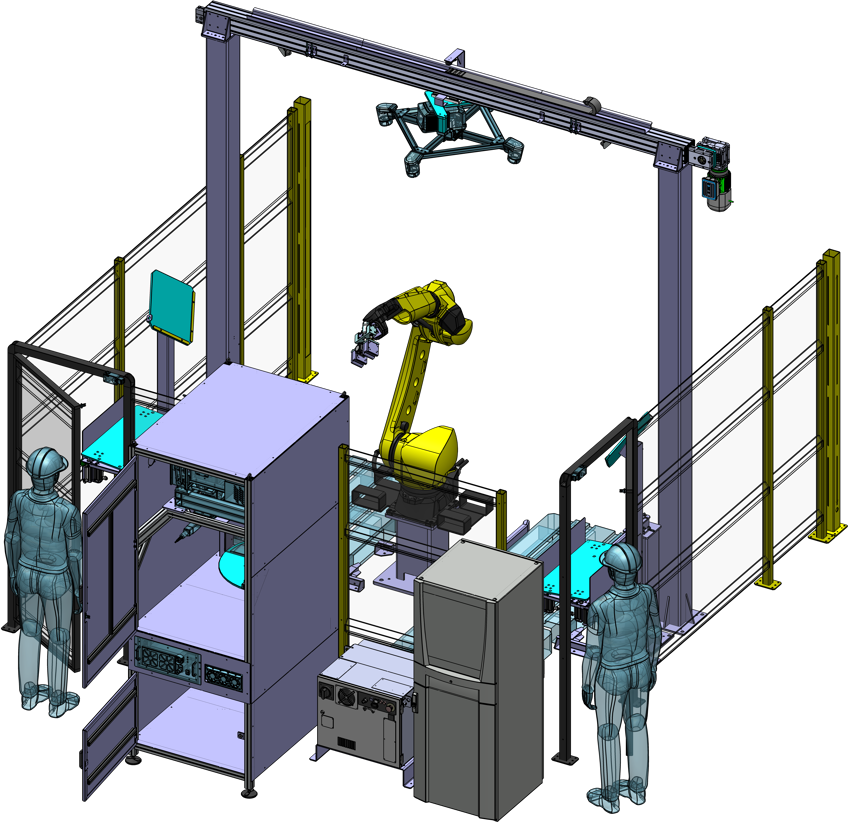

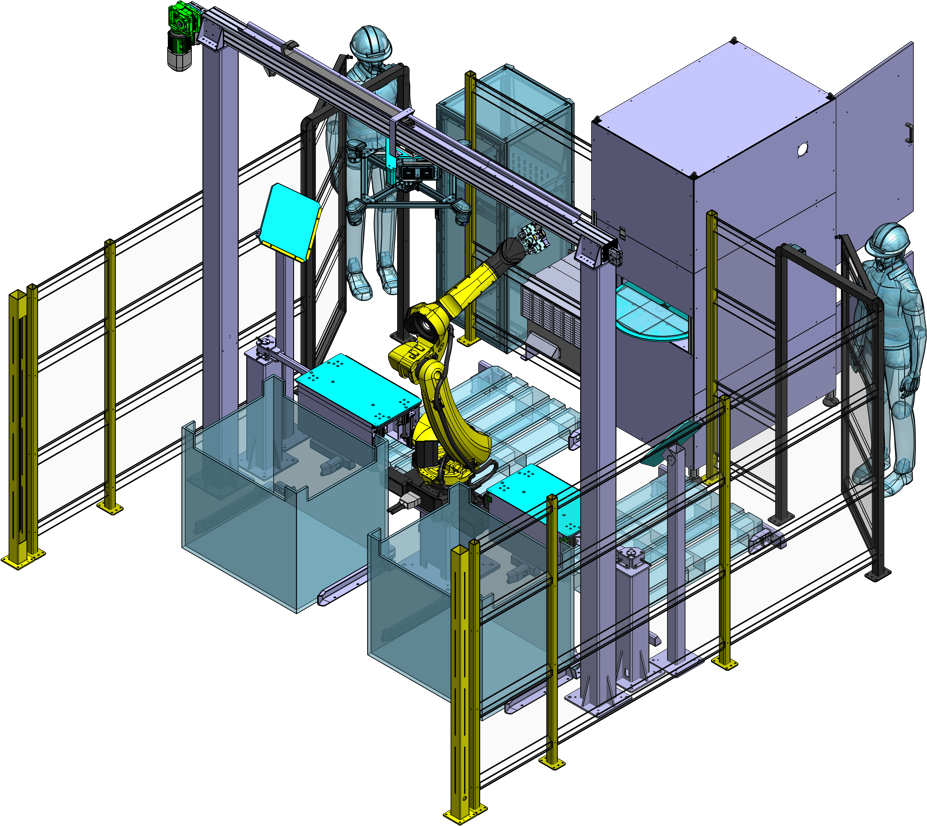

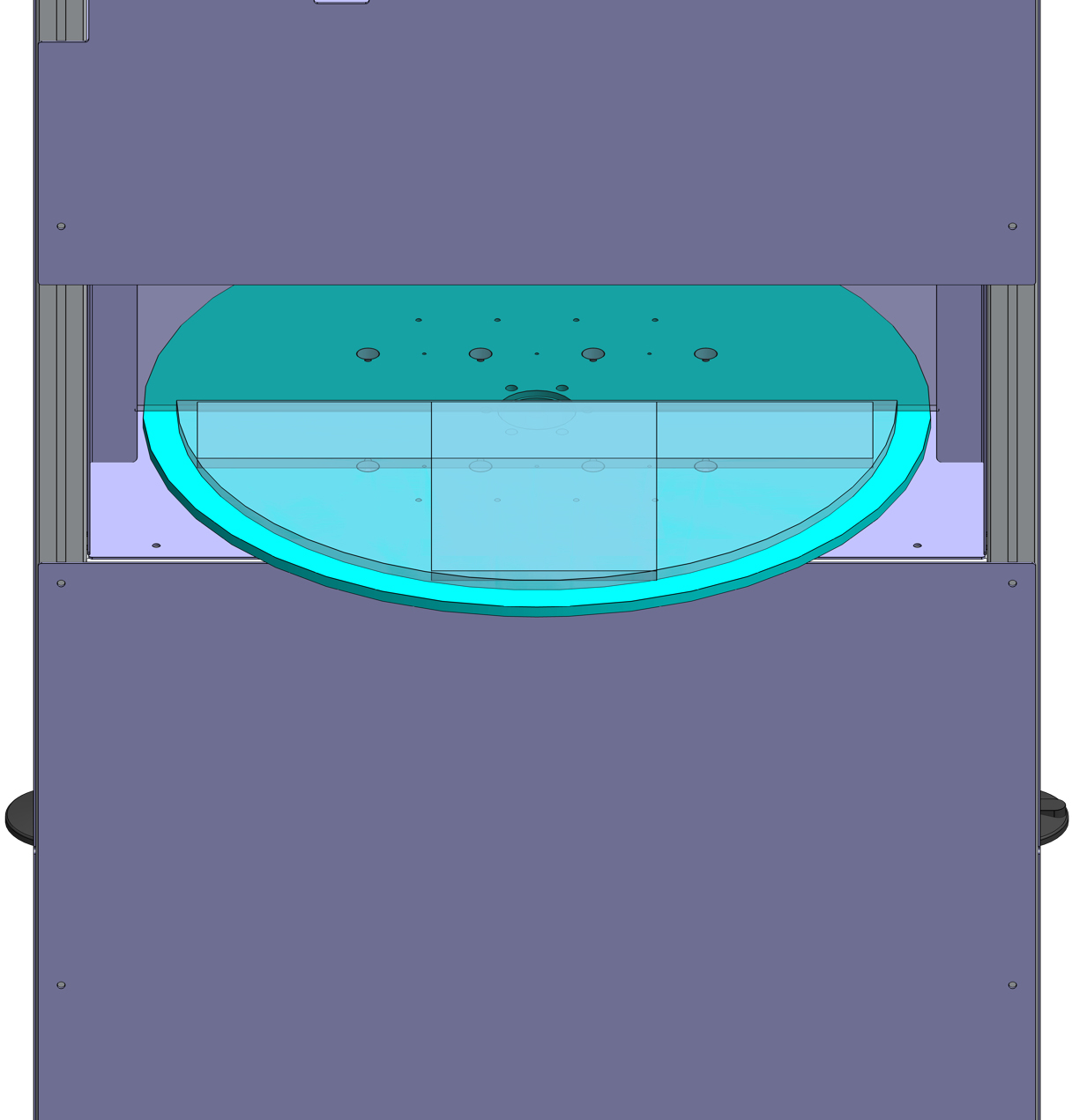

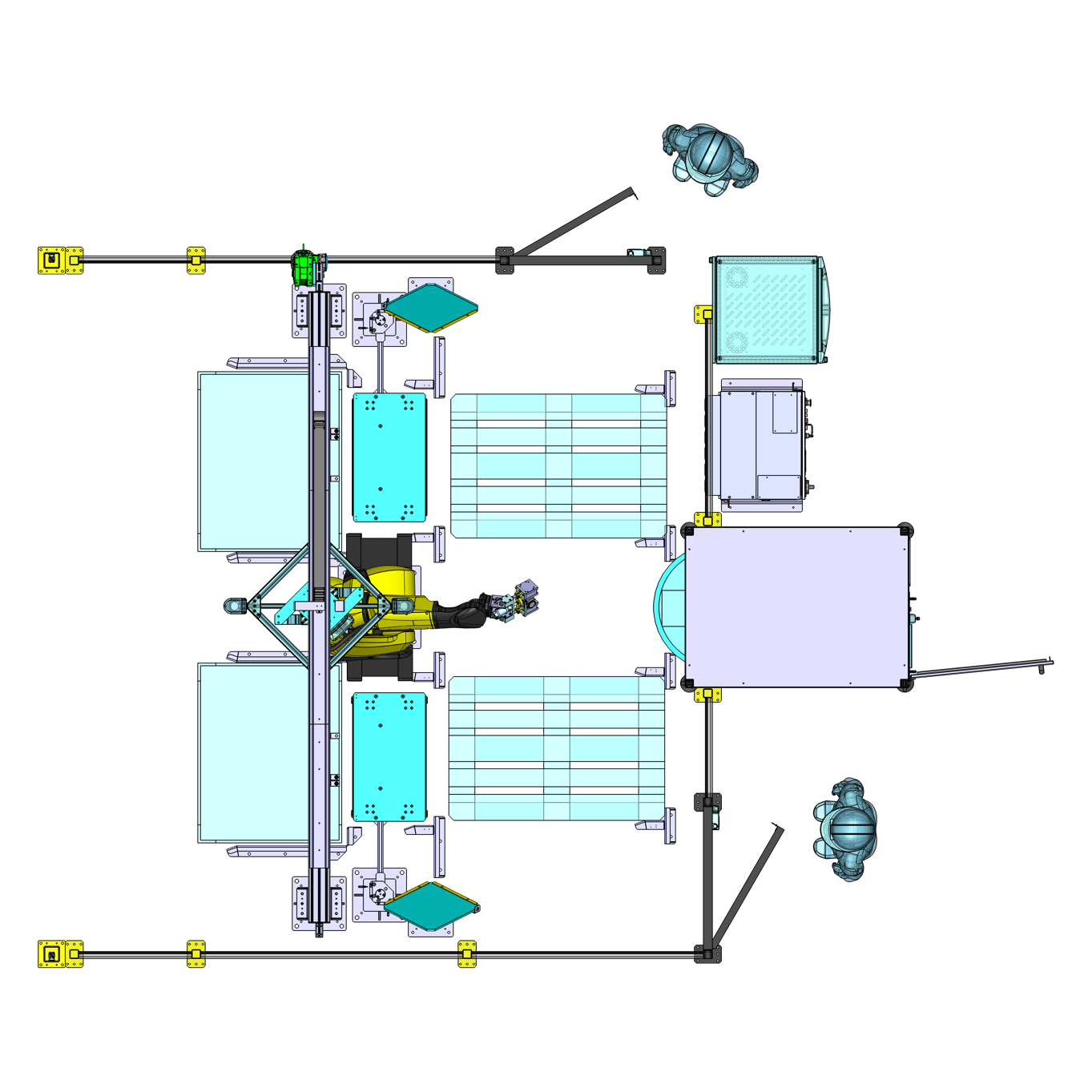

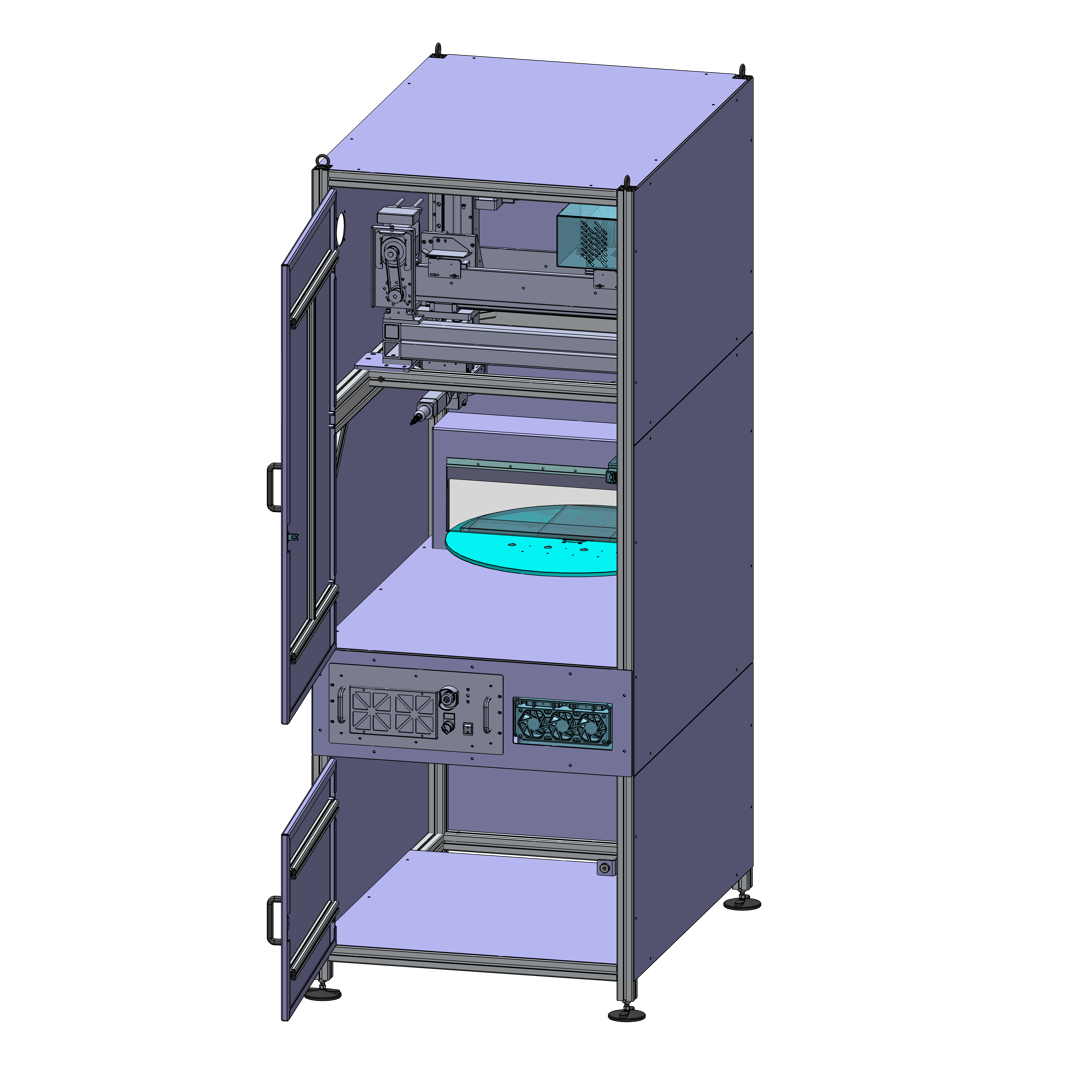

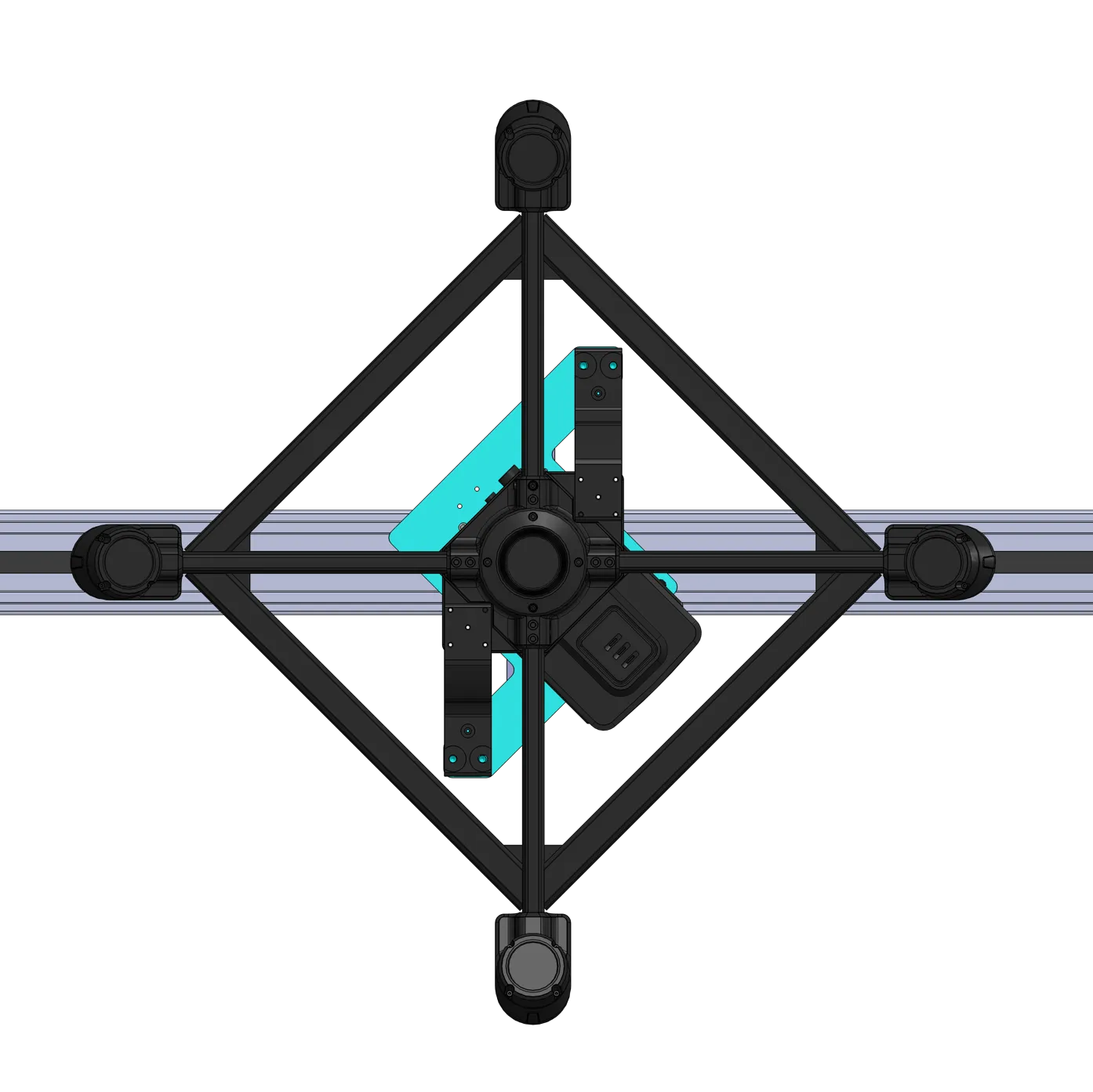

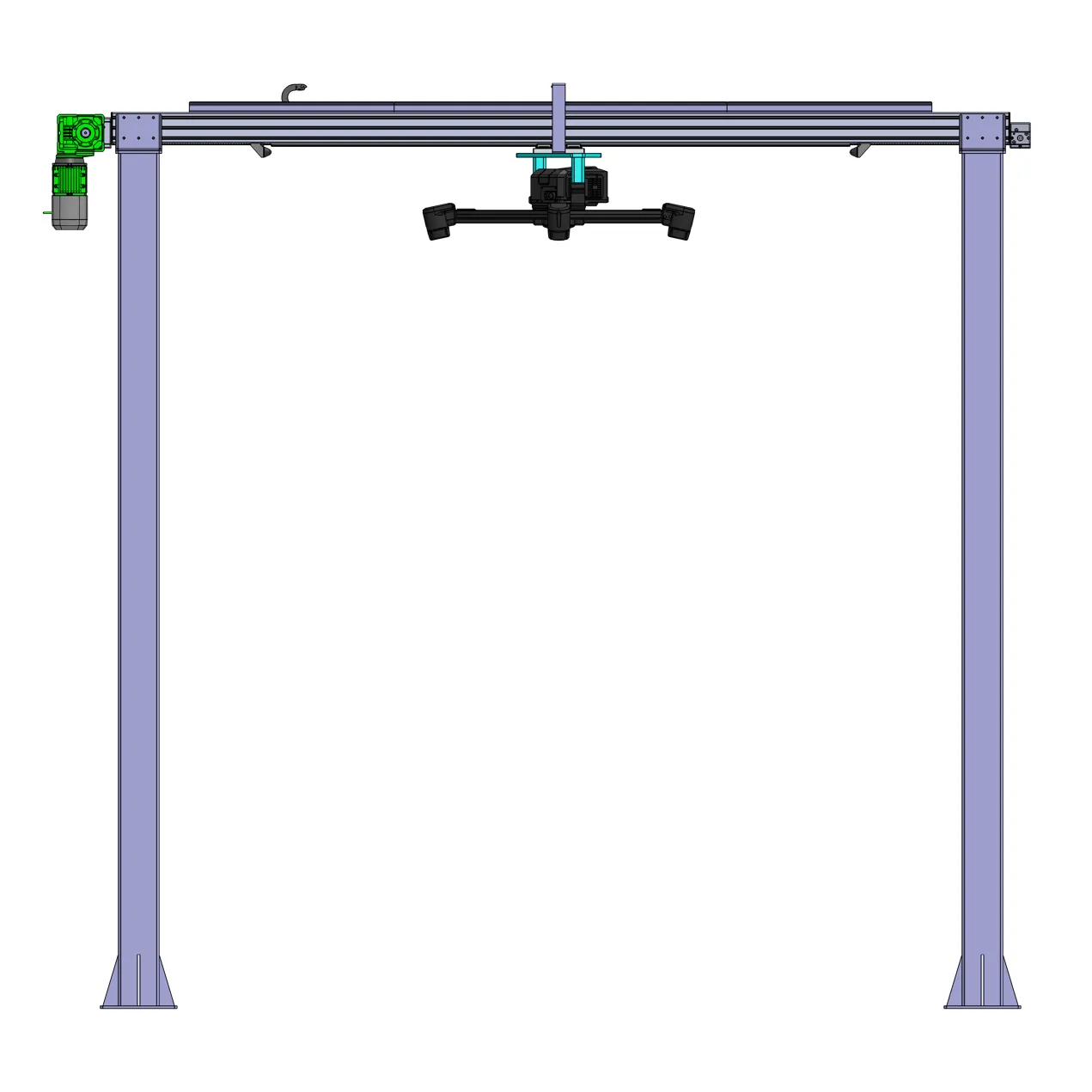

HT srl needed a customised robotic automation solution to optimise the process of picking blades in bulk from metal containers and palletising them on two separate pallets. The system also had to integrate seamlessly with a LASIT POWERMARK VP 200 SB laser marker for marking components.

MAIN REQUIREMENTS TO BE MET

:

- Automate automatic picking from bins

- Maximum cycle time: 15 secondi

- Bin emptying >97% su 3.000 pezzi

- ll integration with LASIT system and marker

- Reduce human error and increase production line efficiency