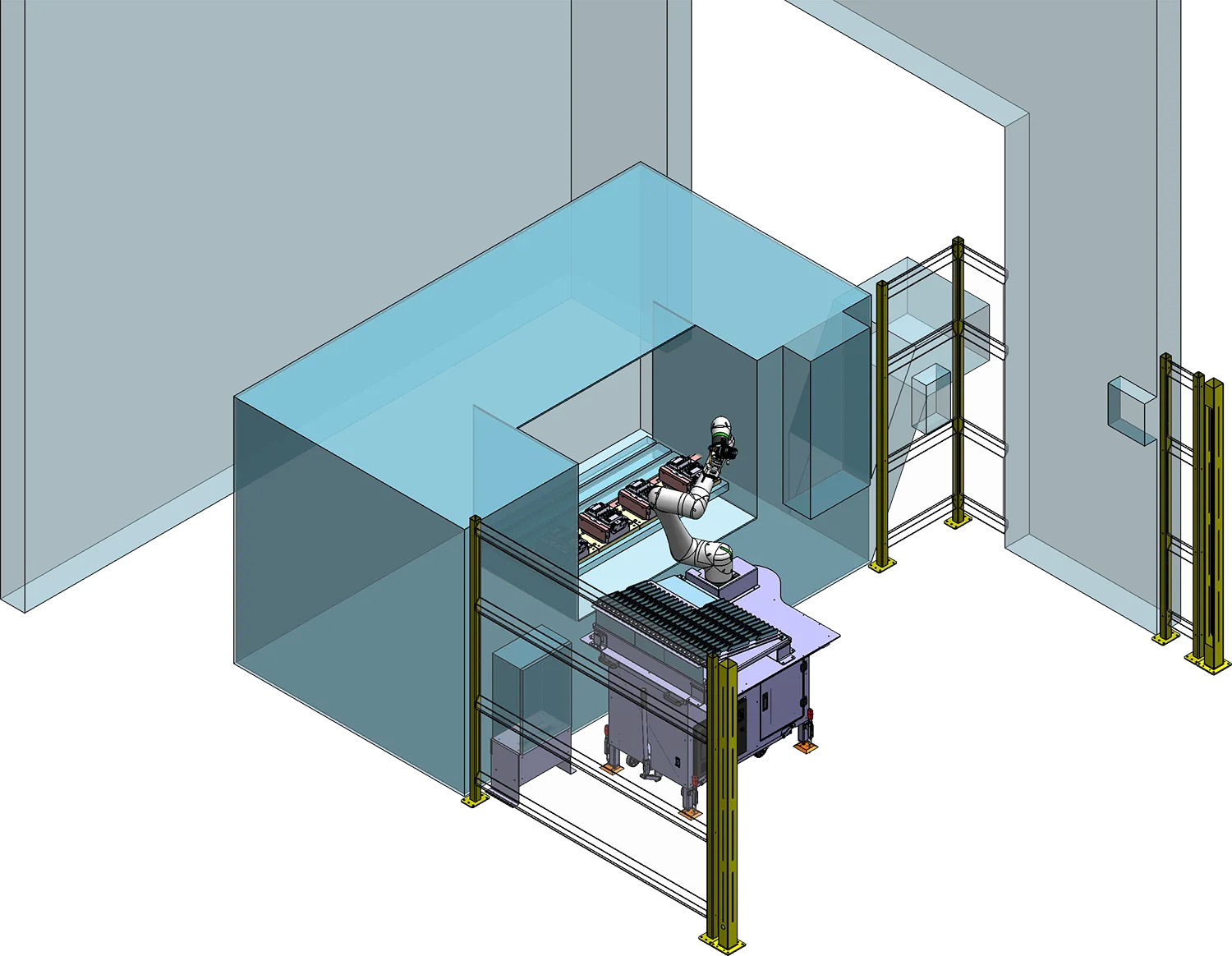

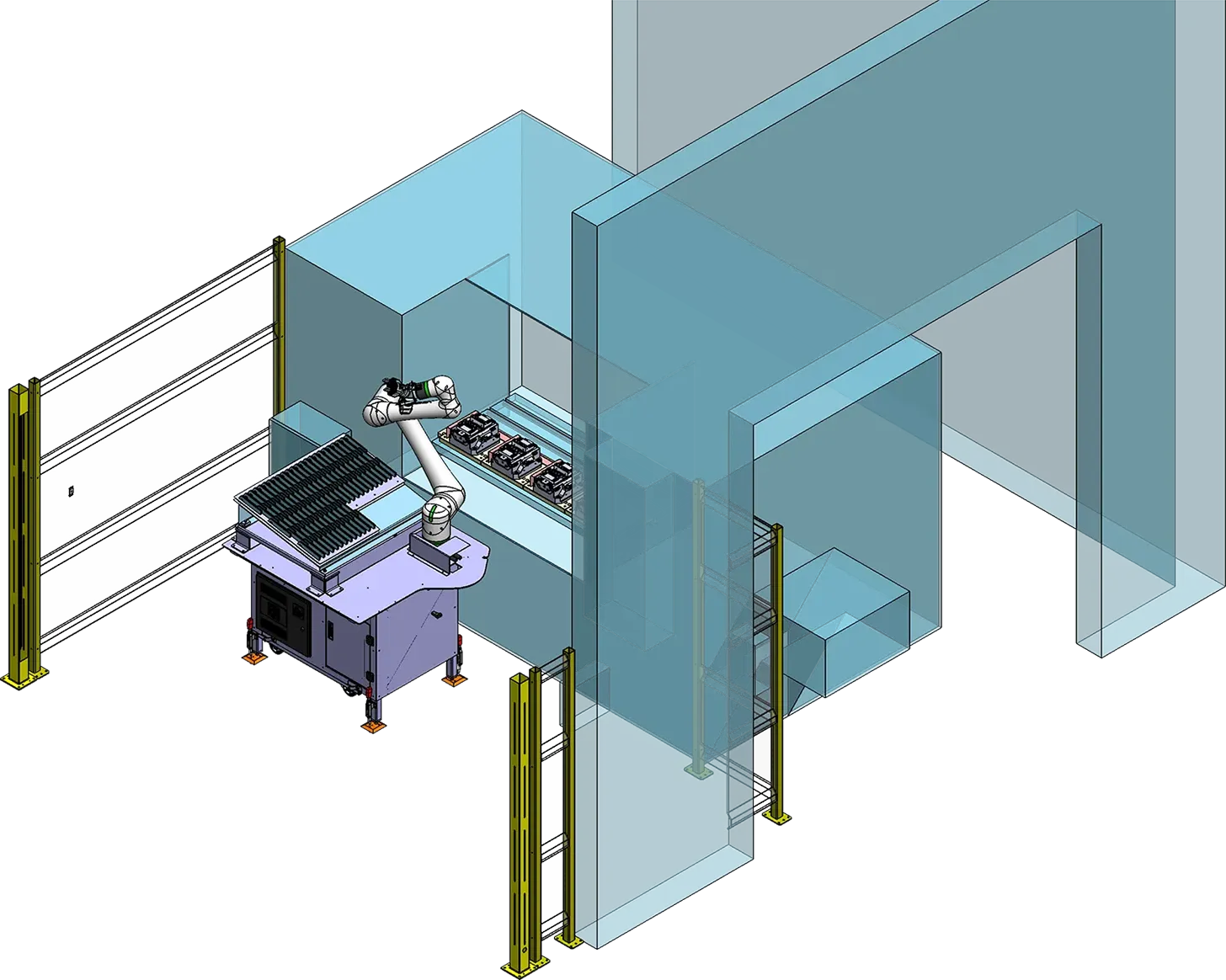

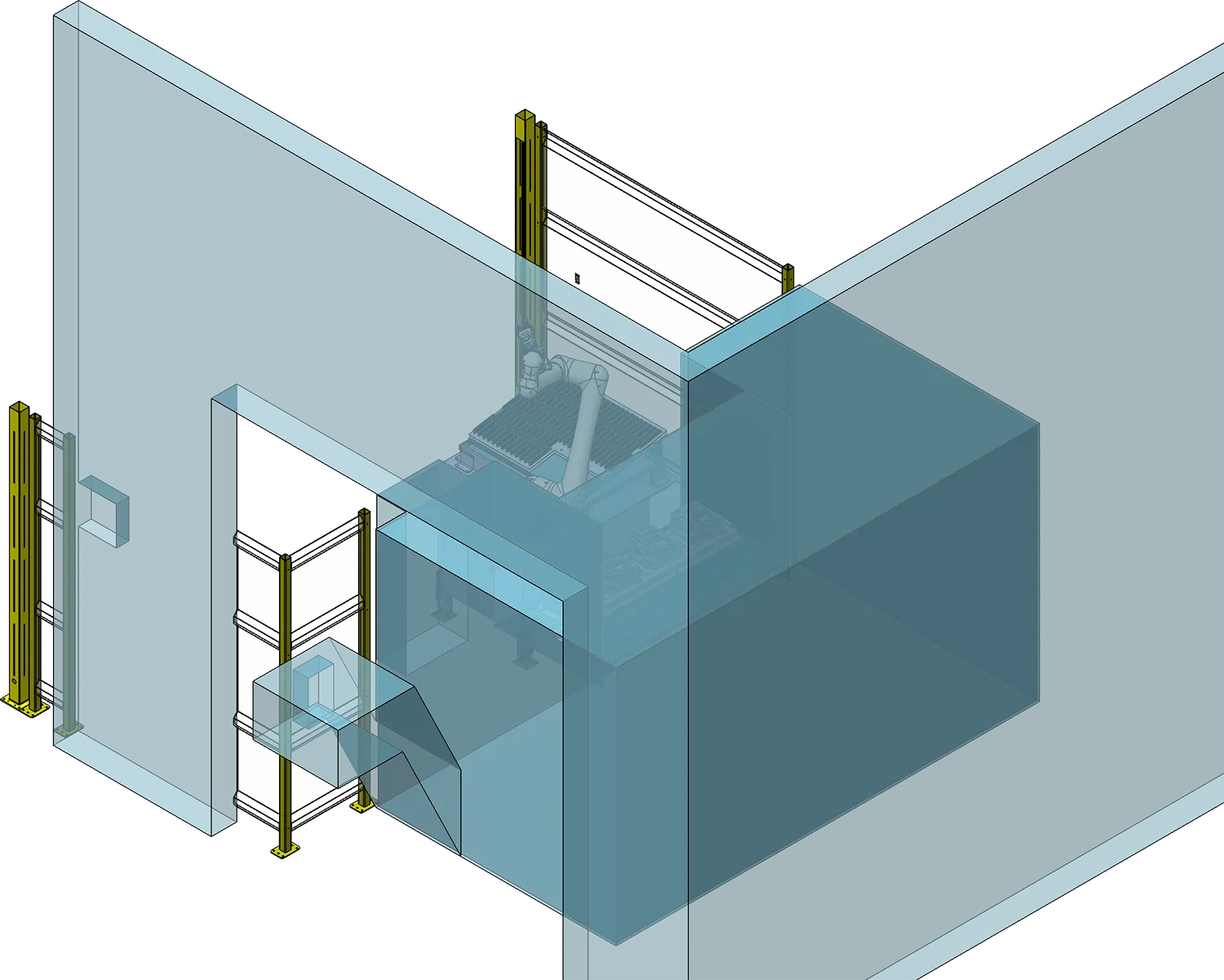

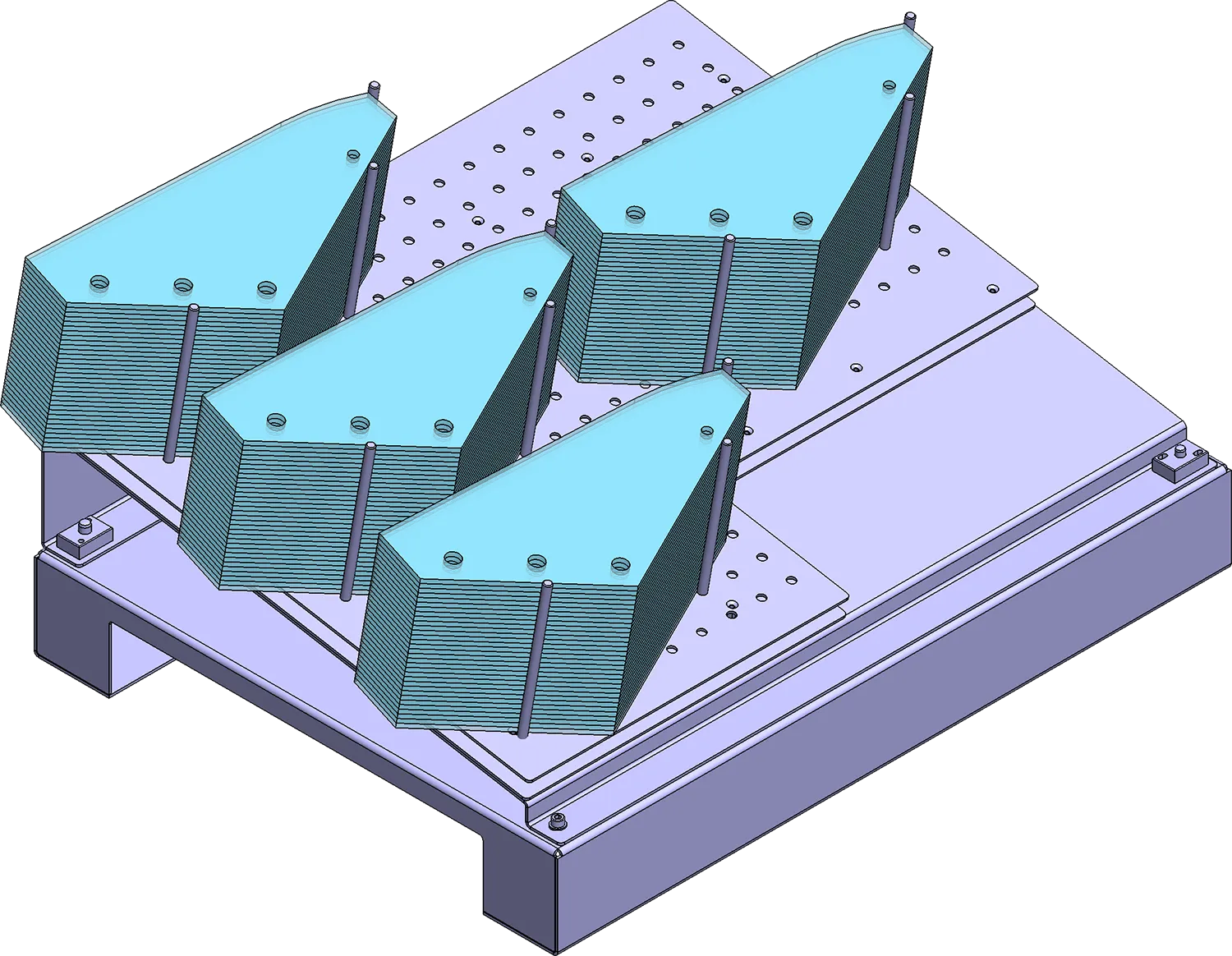

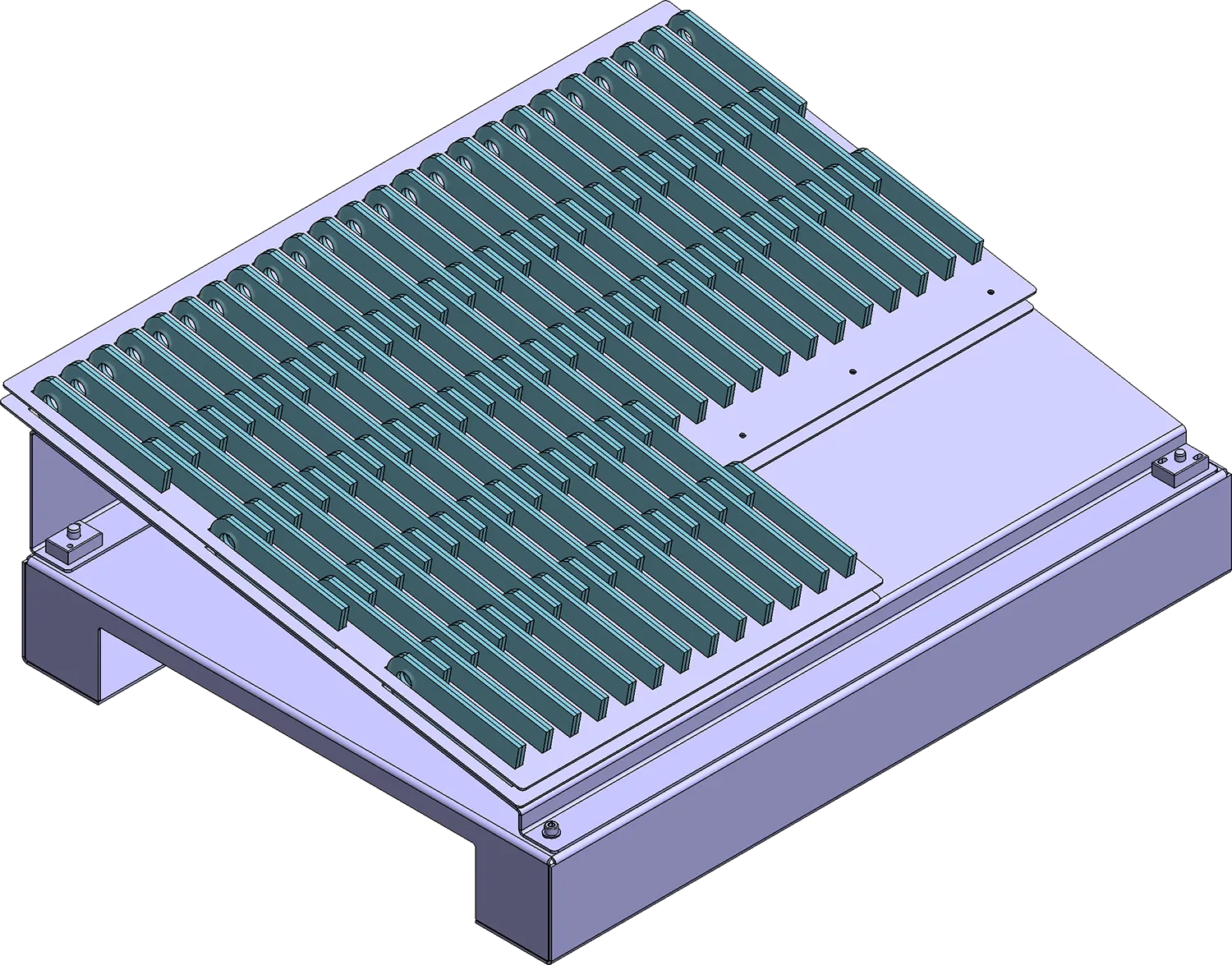

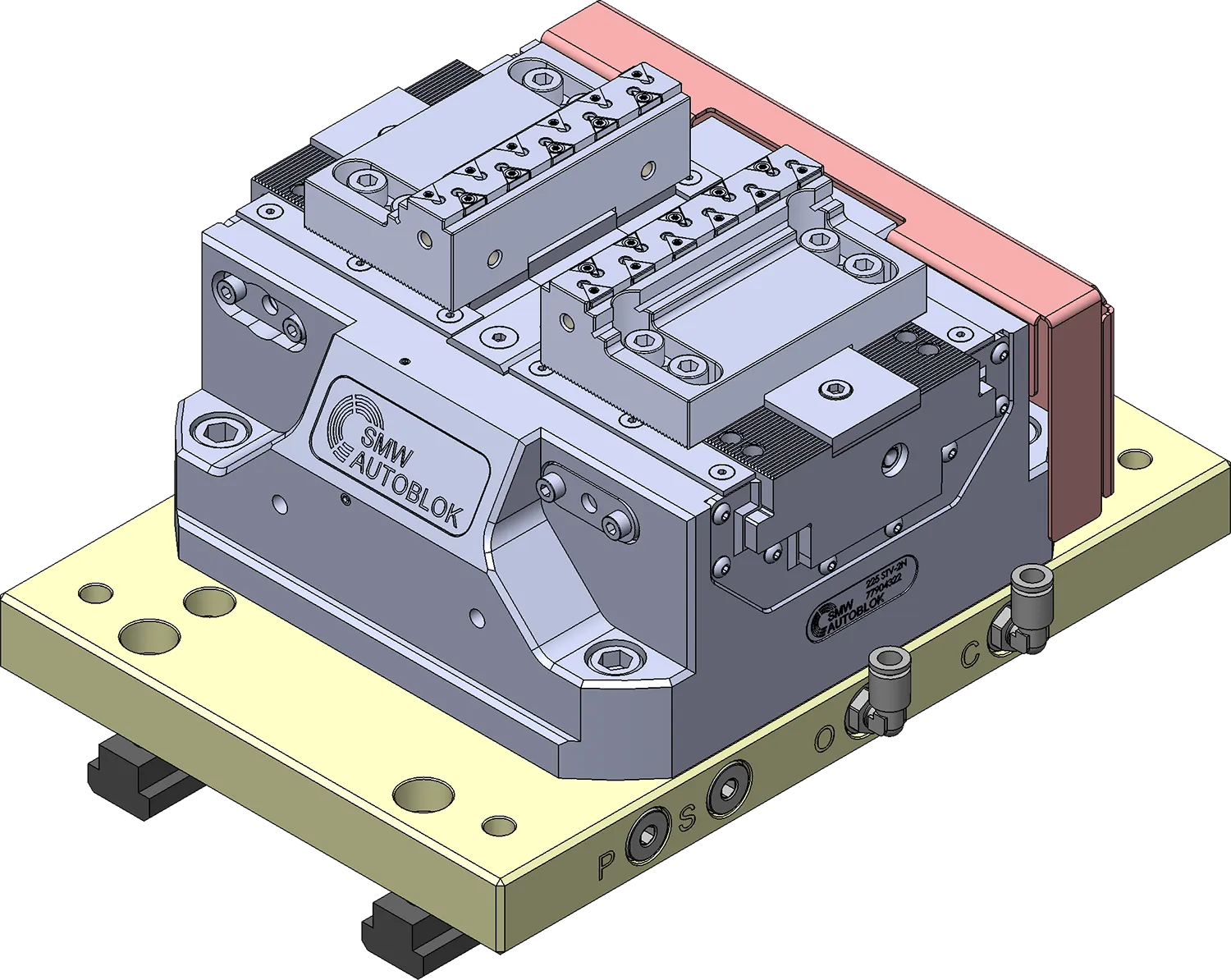

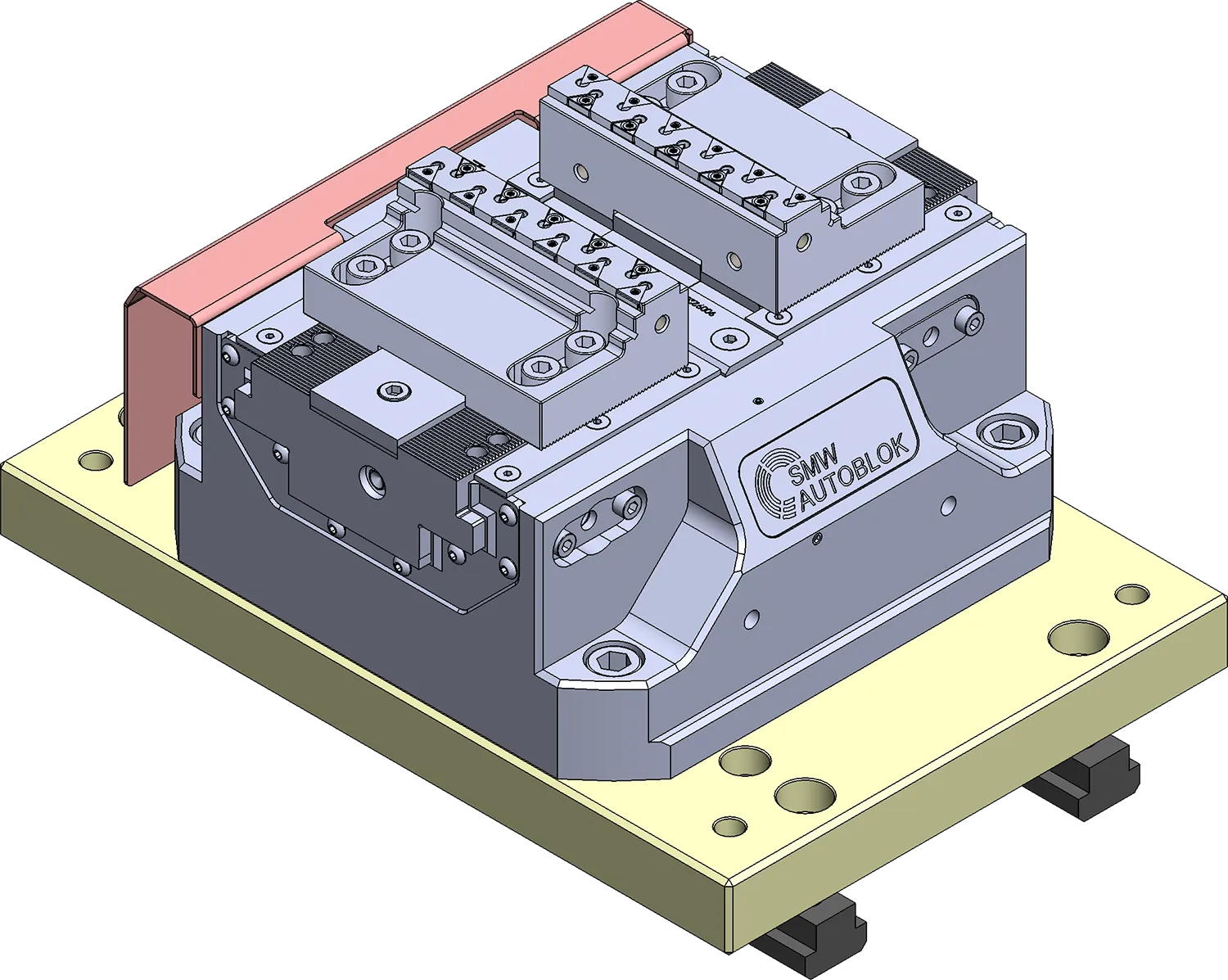

HT srl decided to integrate our RoboFeed C20 Custom into its machine park. This choice was motivated by the need to optimise the milling process of two machining centres, without compromising the space and safety of its own employees, thus being able to use a single robotized island on two different machining centres.

Solution: RoboFeed C20 Custom

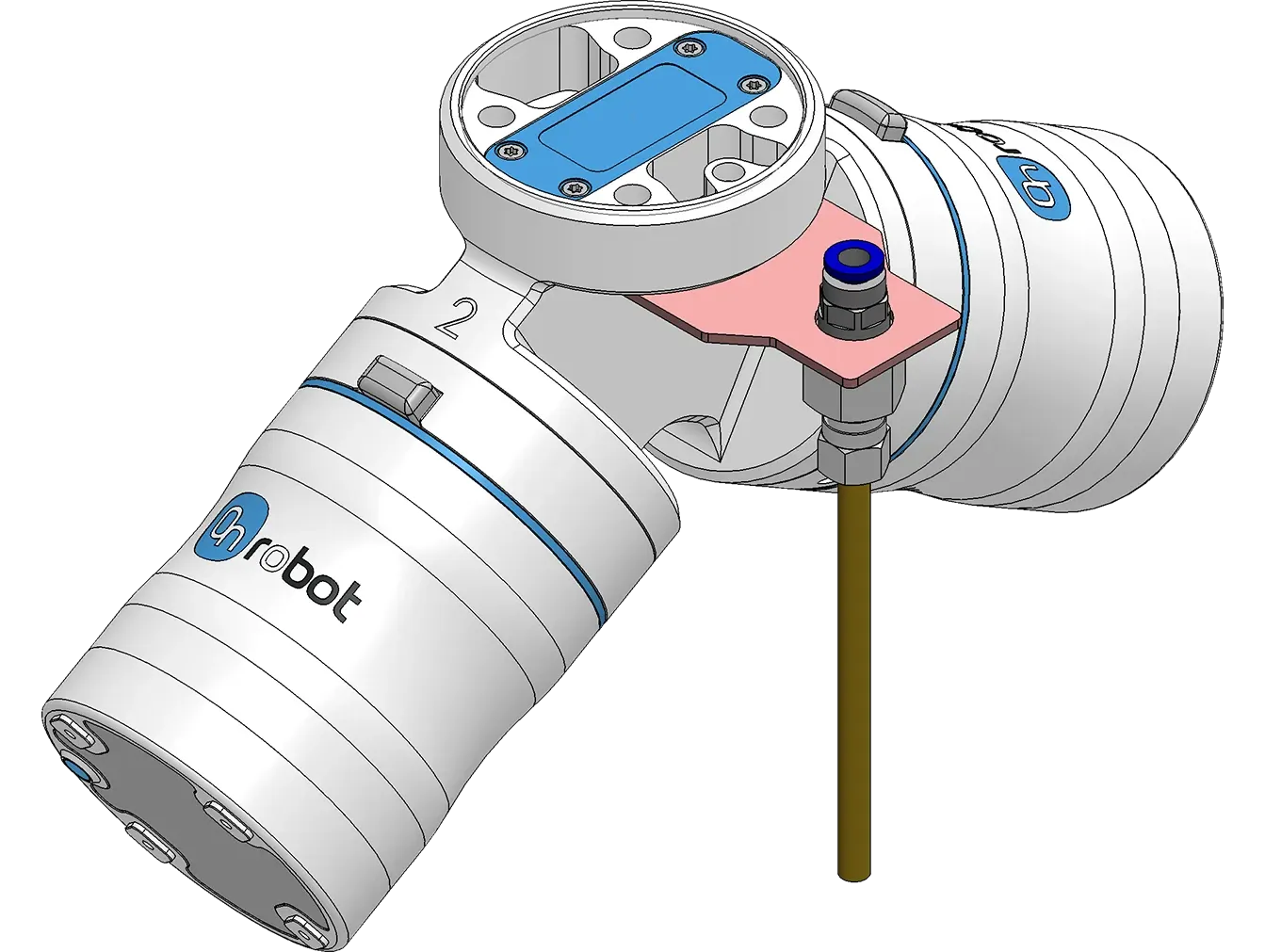

After the first meeting with the customer, the technical team found the RoboFeed C20 robot island the most appropriate choice to be able to respond and achieve the objectives set, using the FANUC 10 kg Cobot, CRX10iA/L, to be able to process all types of parts.