Identified challenges

After the first meeting with the customer together with our technicians, the situation and the many critical points to be addressed were clear:

Metalmechanical

Bergamo, Italy

Alumat, a company specializing in the manufacture of dies for aluminum extrusion

To restore the operation of a robotic cell with Fanuc robots that had been in operation for over 15 years, solving different issues that were hindering the normal running of the production activity.

to modernize a robotic cell while maintaining the existing hardware, ensuring minimized downtime, and developing open, customizable software that complies with Industry 4.0 standards

After the first meeting with the customer together with our technicians, the situation and the many critical points to be addressed were clear:

After a thorough analysis, we developed a structured intervention plan:

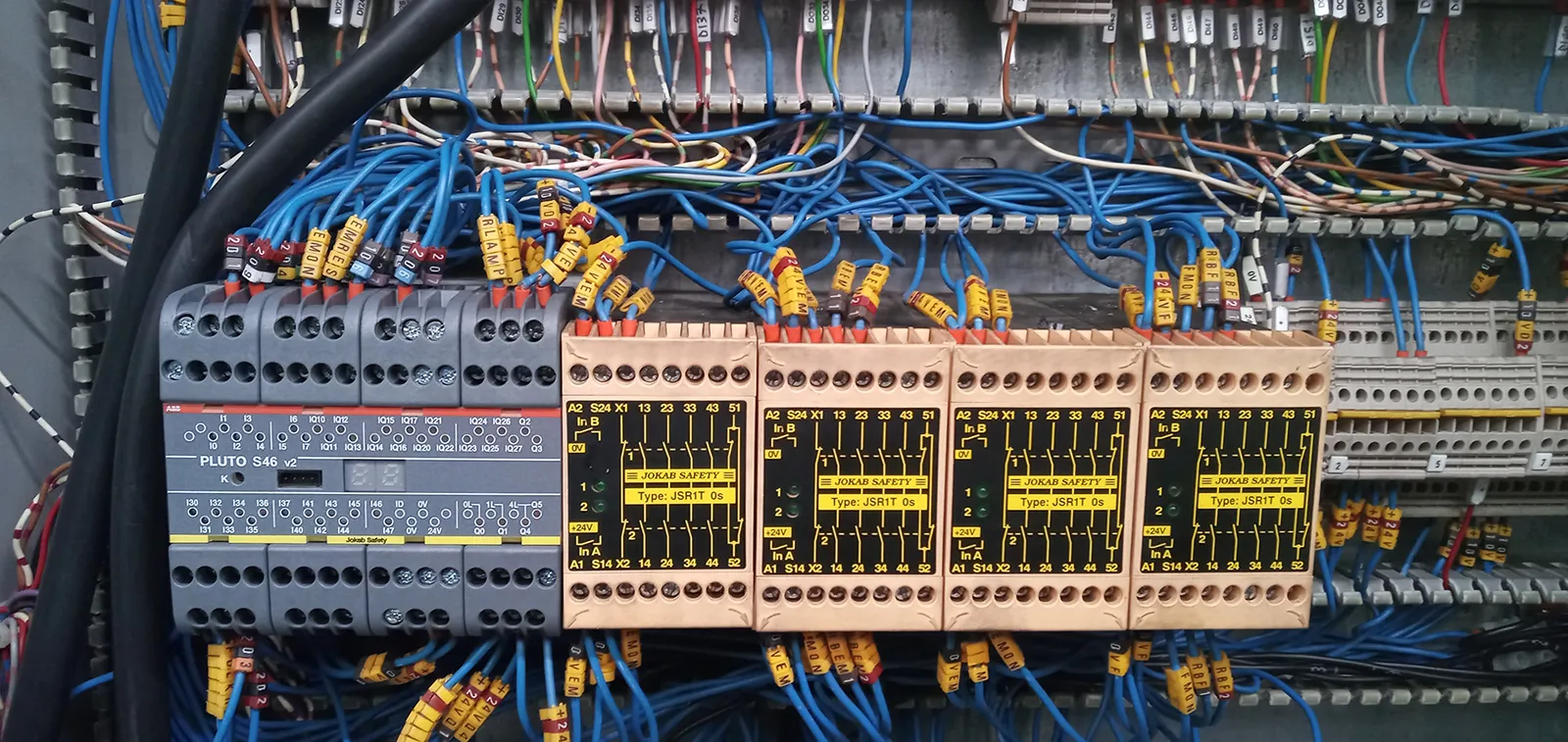

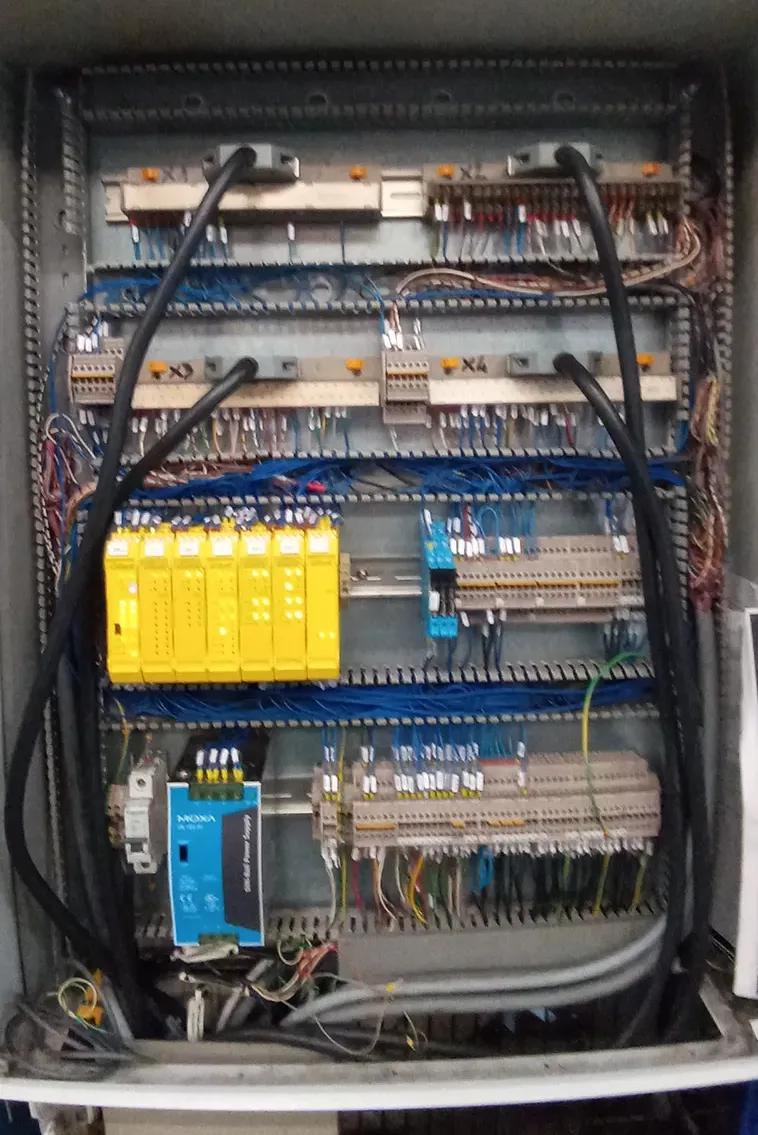

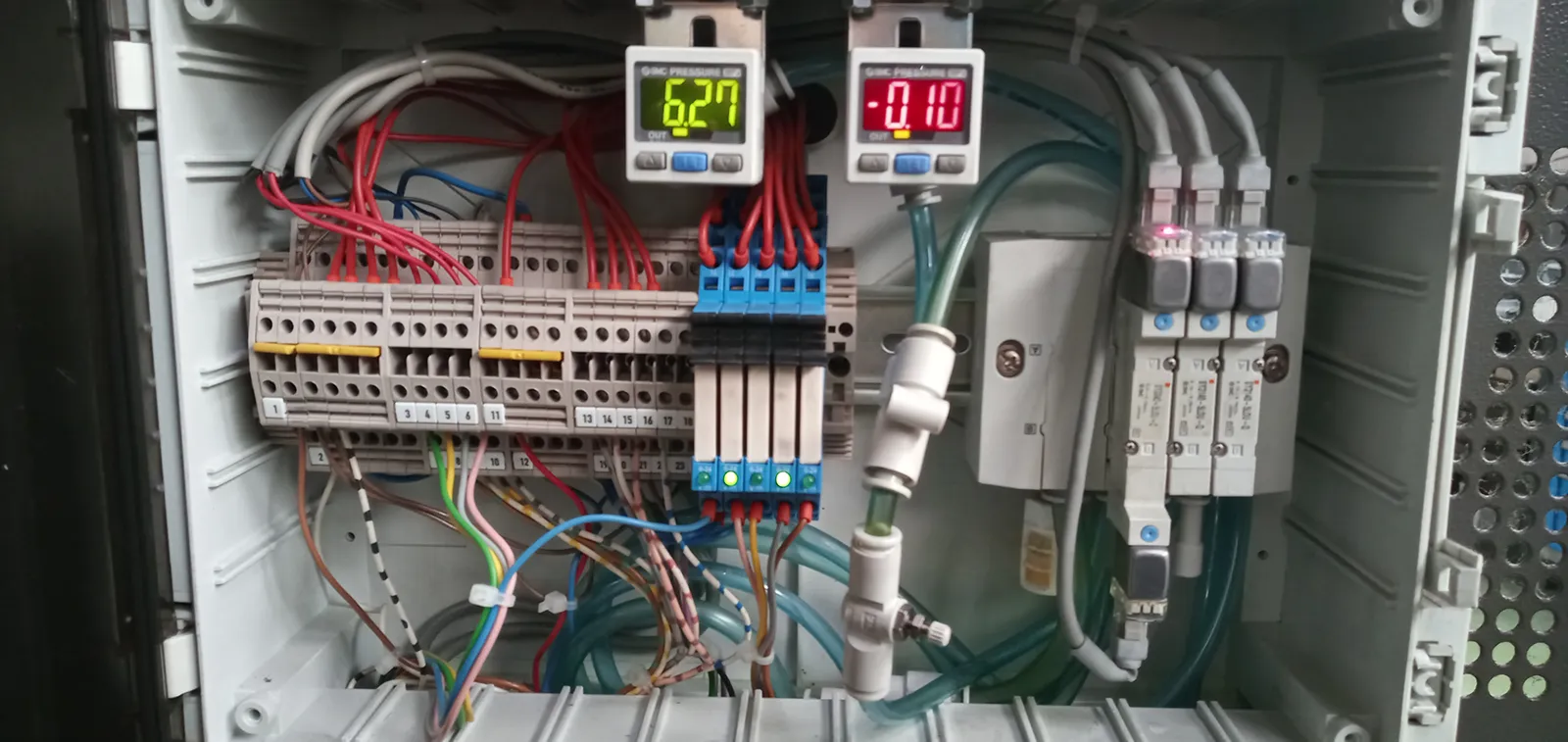

with new standardized control units and complete refurbishment of the control cabinet.

aon board robot, making it more understandable and flexible.

to integrate the new software with existing business systems, ensuring operational consistency

the new system was designed to also work with the old supervisor, ensuring production continuity during the transition phases.

We reconstructed the missing wiring diagram and modernized the cell with advanced tools such as RoboGuide.

As a result, we focused on creating tailored software that could enable the planning of handling missions with greater accuracy and reliability.

The electrical cabinet refurbishment involved replacing obsolete components, improving reliability and reducing failures.

Thanks to these interventions and careful planning, unmanned production was interrupted for only one night, without compromising order delivery delays.

New documentation and software simplified interfacing, which was completed in only 3 days.

The robotic cell is now completely revamped and integrated into business processes.

Among the main benefits achieved:

The customer can now operate autonomously and safely, with the peace of mind of having a documented and reliable system.

Production manager

Concluding our intervention, the client was able to replace one of the machine tools connected to the cell in just three days, a task that would have been unthinkable before.

Production is now smooth, safe, and ready to meet future challenges with a documented and customizable system.

Do you have a robotic cell to upgrade? Contact us today to find out how we can transform your robotic plant into a modern, reliable asset that meets Industry 4.0 standards.

Fill out the form and request a personalized consultation