roi

calculator

INVEST IN MACHINE TOOL AUTOMATION AND FIND OUT HOW MUCH YOU REALLY SAVE!

Assistec and ROI-Calculator by FANUC help you calculate an accurate estimate of the return on investment for automated servicing robots.

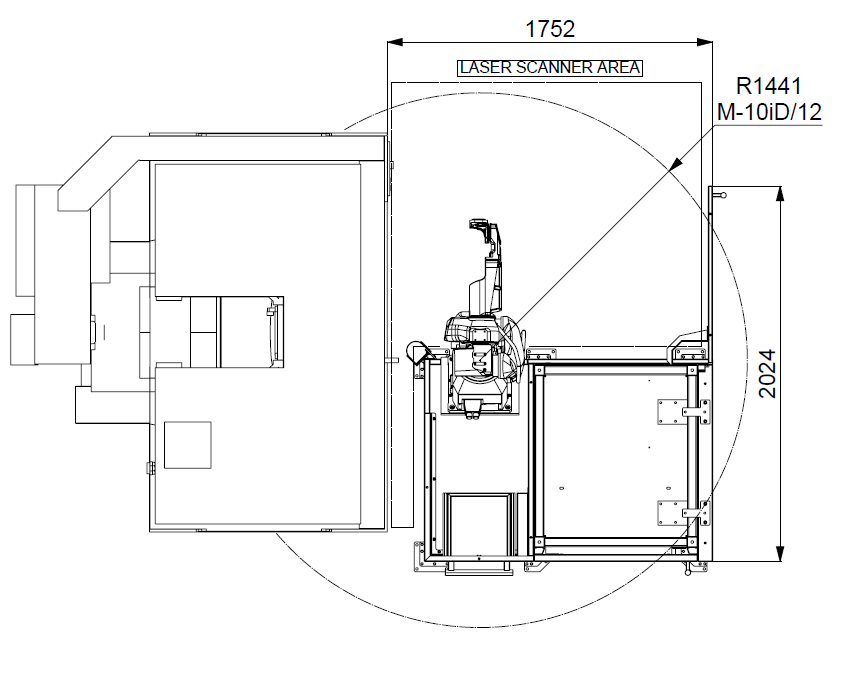

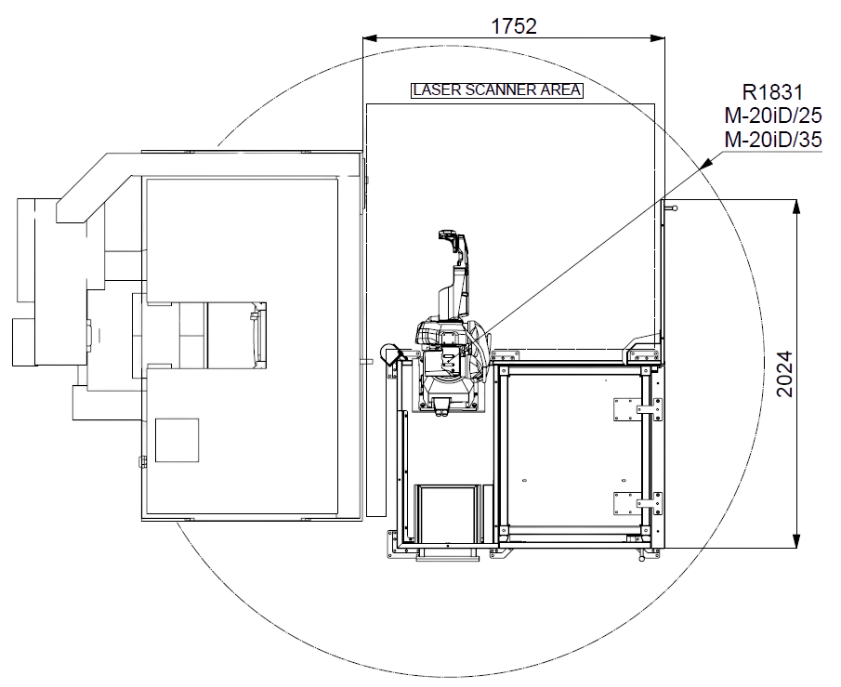

Assis-tec’s research and development department has developed an effective, fully-automated solution for servicing machine tools. Fanuc efficiency and reliability is the basis of our Robo feed machines.

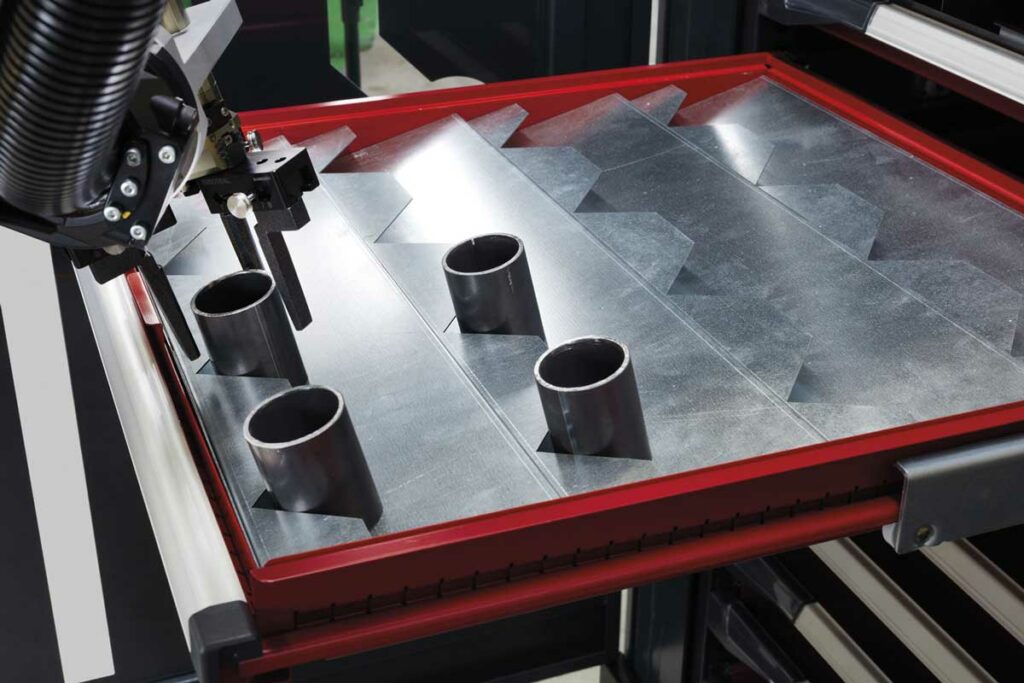

The models of the A2 SERIES are designed with drawers that are fully removable from the island and interchangeable, offering an operational availability of up to 16 drawers.

Immediate monitoring of production progress thanks to machine-side LED indicators.

The rapid installation and configuration as well as its compact dimensions allow perfect integration in the workshop.

By combining several robots assigned to different stages of the production process, it is possible to improve the degree of automation of the entire production line.

jaws and optional excluded

(*indicative data to be verified according to model choice)

Centring station

Tilting station

Deburring station

Deionisation station

Redevelopment station

Assistec and ROI-Calculator by FANUC help you calculate an accurate estimate of the return on investment for automated servicing robots.